Are you a seasoned Lead Burner Supervisor seeking a new career path? Discover our professionally built Lead Burner Supervisor Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

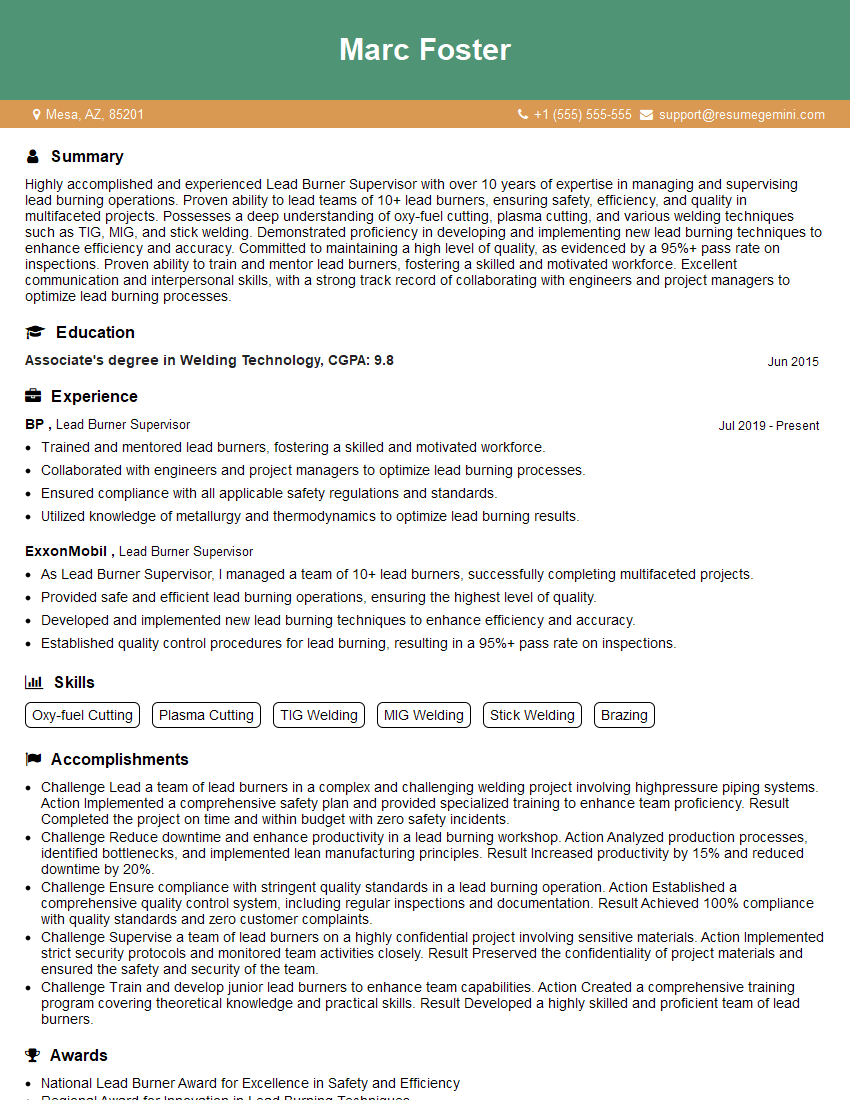

Marc Foster

Lead Burner Supervisor

Summary

Highly accomplished and experienced Lead Burner Supervisor with over 10 years of expertise in managing and supervising lead burning operations. Proven ability to lead teams of 10+ lead burners, ensuring safety, efficiency, and quality in multifaceted projects. Possesses a deep understanding of oxy-fuel cutting, plasma cutting, and various welding techniques such as TIG, MIG, and stick welding. Demonstrated proficiency in developing and implementing new lead burning techniques to enhance efficiency and accuracy. Committed to maintaining a high level of quality, as evidenced by a 95%+ pass rate on inspections. Proven ability to train and mentor lead burners, fostering a skilled and motivated workforce. Excellent communication and interpersonal skills, with a strong track record of collaborating with engineers and project managers to optimize lead burning processes.

Education

Associate’s degree in Welding Technology

June 2015

Skills

- Oxy-fuel Cutting

- Plasma Cutting

- TIG Welding

- MIG Welding

- Stick Welding

- Brazing

Work Experience

Lead Burner Supervisor

- Trained and mentored lead burners, fostering a skilled and motivated workforce.

- Collaborated with engineers and project managers to optimize lead burning processes.

- Ensured compliance with all applicable safety regulations and standards.

- Utilized knowledge of metallurgy and thermodynamics to optimize lead burning results.

Lead Burner Supervisor

- As Lead Burner Supervisor, I managed a team of 10+ lead burners, successfully completing multifaceted projects.

- Provided safe and efficient lead burning operations, ensuring the highest level of quality.

- Developed and implemented new lead burning techniques to enhance efficiency and accuracy.

- Established quality control procedures for lead burning, resulting in a 95%+ pass rate on inspections.

Accomplishments

- Challenge Lead a team of lead burners in a complex and challenging welding project involving highpressure piping systems. Action Implemented a comprehensive safety plan and provided specialized training to enhance team proficiency. Result Completed the project on time and within budget with zero safety incidents.

- Challenge Reduce downtime and enhance productivity in a lead burning workshop. Action Analyzed production processes, identified bottlenecks, and implemented lean manufacturing principles. Result Increased productivity by 15% and reduced downtime by 20%.

- Challenge Ensure compliance with stringent quality standards in a lead burning operation. Action Established a comprehensive quality control system, including regular inspections and documentation. Result Achieved 100% compliance with quality standards and zero customer complaints.

- Challenge Supervise a team of lead burners on a highly confidential project involving sensitive materials. Action Implemented strict security protocols and monitored team activities closely. Result Preserved the confidentiality of project materials and ensured the safety and security of the team.

- Challenge Train and develop junior lead burners to enhance team capabilities. Action Created a comprehensive training program covering theoretical knowledge and practical skills. Result Developed a highly skilled and proficient team of lead burners.

Awards

- National Lead Burner Award for Excellence in Safety and Efficiency

- Regional Award for Innovation in Lead Burning Techniques

- CompanyWide Recognition for Outstanding Performance as Lead Burner Supervisor

- Departmental Safety Award for maintaining an exemplary safety record

Certificates

- AWS Certified Welding Inspector (CWI)

- ASME Certified Pressure Vessel Welder

- National Board of Boiler and Pressure Vessel Inspectors (NBBI)

- API 510 Pressure Vessel Inspector Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Lead Burner Supervisor

- Quantify your accomplishments whenever possible. For instance, instead of simply stating that you ‘led a team of lead burners,’ you could say ‘Led a team of 10+ lead burners, successfully completing multifaceted projects, resulting in a 95%+ pass rate on inspections.’

- Use action verbs to highlight your skills and experience. For example, instead of saying ‘Responsible for training lead burners,’ you could say ‘Trained and mentored lead burners, fostering a skilled and motivated workforce.’

- Tailor your resume to each specific job you apply for. Be sure to highlight the skills and experience that are most relevant to the position you are seeking.

- Proofread your resume carefully before submitting it. Make sure there are no errors in grammar or spelling.

Essential Experience Highlights for a Strong Lead Burner Supervisor Resume

- Supervised and managed a team of over 10 lead burners, ensuring safety, efficiency, and quality in multifaceted projects.

- Provided safe and efficient lead burning operations, ensuring the highest level of quality.

- Developed and implemented new lead burning techniques to enhance efficiency and accuracy.

- Established quality control procedures for lead burning, resulting in a 95%+ pass rate on inspections.

- Trained and mentored lead burners, fostering a skilled and motivated workforce.

- Collaborated with engineers and project managers to optimize lead burning processes.

- Ensured compliance with all applicable safety regulations and standards.

Frequently Asked Questions (FAQ’s) For Lead Burner Supervisor

What are the key responsibilities of a Lead Burner Supervisor?

The key responsibilities of a Lead Burner Supervisor include supervising and managing a team of lead burners, ensuring safety, efficiency, and quality in multifaceted projects; developing and implementing new lead burning techniques to enhance efficiency and accuracy; establishing quality control procedures for lead burning; training and mentoring lead burners; collaborating with engineers and project managers to optimize lead burning processes; and ensuring compliance with all applicable safety regulations and standards.

What are the educational requirements to become a Lead Burner Supervisor?

Most Lead Burner Supervisors have at least an Associate’s degree in Welding Technology. However, some employers may require a Bachelor’s degree in a related field, such as Mechanical Engineering or Manufacturing Engineering.

What are the skills and experience required to become a Lead Burner Supervisor?

Lead Burner Supervisors should have a strong understanding of oxy-fuel cutting, plasma cutting, and various welding techniques such as TIG, MIG, and stick welding. They should also be proficient in developing and implementing new lead burning techniques to enhance efficiency and accuracy. Additionally, Lead Burner Supervisors should have excellent communication and interpersonal skills, as they are responsible for training and mentoring lead burners and collaborating with engineers and project managers.

What is the career outlook for Lead Burner Supervisors?

The career outlook for Lead Burner Supervisors is expected to be good over the next few years. As the construction industry continues to grow, there will be an increasing demand for qualified Lead Burner Supervisors to oversee lead burning operations.

What are the earning prospects for Lead Burner Supervisors?

Lead Burner Supervisors can earn a good salary, depending on their experience and the size of the company they work for. According to the U.S. Bureau of Labor Statistics, the median annual salary for Welding Supervisors and Managers was $69,980 in May 2021.

What are the benefits of becoming a Lead Burner Supervisor?

There are many benefits to becoming a Lead Burner Supervisor, including the opportunity to earn a good salary, work in a challenging and rewarding career, and make a difference in the construction industry.

What are the challenges of becoming a Lead Burner Supervisor?

There are also some challenges to becoming a Lead Burner Supervisor, including the need to have a strong understanding of oxy-fuel cutting, plasma cutting, and various welding techniques, as well as the ability to manage a team of lead burners and collaborate with engineers and project managers.

How can I become a Lead Burner Supervisor?

To become a Lead Burner Supervisor, you will need to have at least an Associate’s degree in Welding Technology, as well as several years of experience in lead burning. You will also need to have a strong understanding of oxy-fuel cutting, plasma cutting, and various welding techniques, as well as the ability to manage a team of lead burners and collaborate with engineers and project managers.