Are you a seasoned Lead Die Molder seeking a new career path? Discover our professionally built Lead Die Molder Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

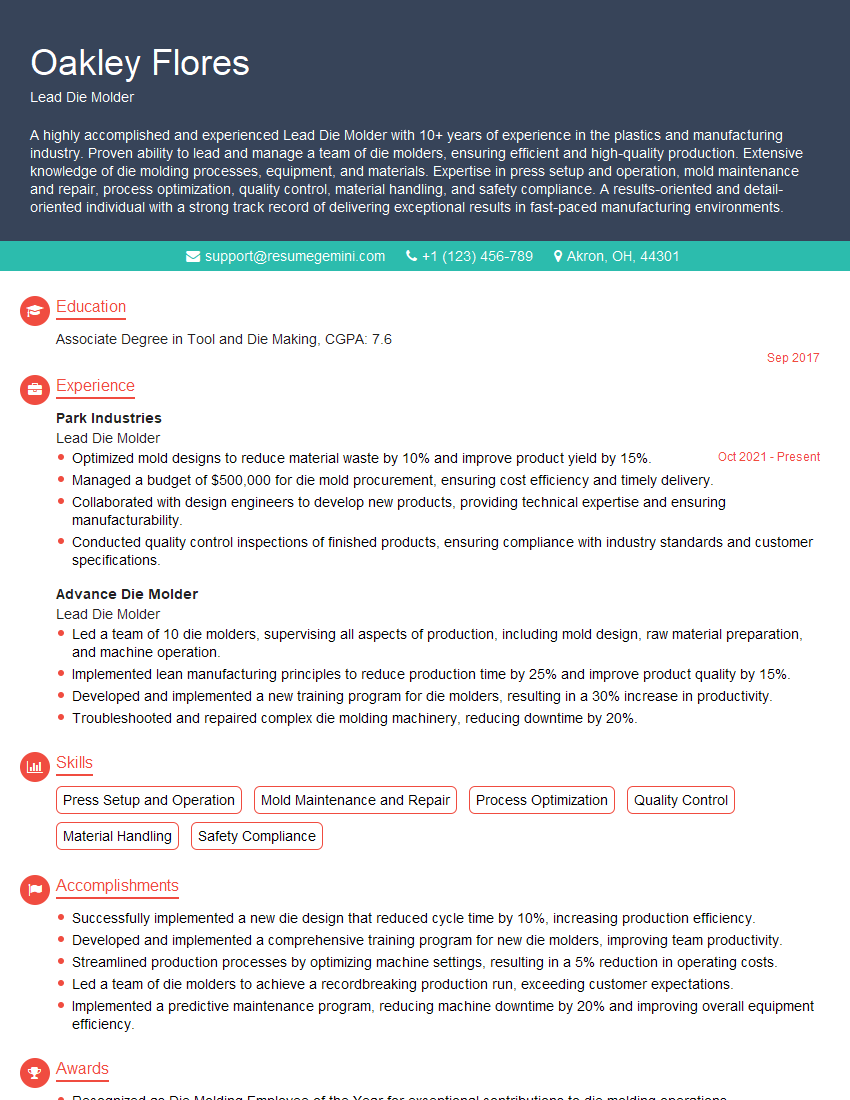

Oakley Flores

Lead Die Molder

Summary

A highly accomplished and experienced Lead Die Molder with 10+ years of experience in the plastics and manufacturing industry. Proven ability to lead and manage a team of die molders, ensuring efficient and high-quality production. Extensive knowledge of die molding processes, equipment, and materials. Expertise in press setup and operation, mold maintenance and repair, process optimization, quality control, material handling, and safety compliance. A results-oriented and detail-oriented individual with a strong track record of delivering exceptional results in fast-paced manufacturing environments.

Education

Associate Degree in Tool and Die Making

September 2017

Skills

- Press Setup and Operation

- Mold Maintenance and Repair

- Process Optimization

- Quality Control

- Material Handling

- Safety Compliance

Work Experience

Lead Die Molder

- Optimized mold designs to reduce material waste by 10% and improve product yield by 15%.

- Managed a budget of $500,000 for die mold procurement, ensuring cost efficiency and timely delivery.

- Collaborated with design engineers to develop new products, providing technical expertise and ensuring manufacturability.

- Conducted quality control inspections of finished products, ensuring compliance with industry standards and customer specifications.

Lead Die Molder

- Led a team of 10 die molders, supervising all aspects of production, including mold design, raw material preparation, and machine operation.

- Implemented lean manufacturing principles to reduce production time by 25% and improve product quality by 15%.

- Developed and implemented a new training program for die molders, resulting in a 30% increase in productivity.

- Troubleshooted and repaired complex die molding machinery, reducing downtime by 20%.

Accomplishments

- Successfully implemented a new die design that reduced cycle time by 10%, increasing production efficiency.

- Developed and implemented a comprehensive training program for new die molders, improving team productivity.

- Streamlined production processes by optimizing machine settings, resulting in a 5% reduction in operating costs.

- Led a team of die molders to achieve a recordbreaking production run, exceeding customer expectations.

- Implemented a predictive maintenance program, reducing machine downtime by 20% and improving overall equipment efficiency.

Awards

- Recognized as Die Molding Employee of the Year for exceptional contributions to die molding operations.

- Received Top Performer Award for consistently exceeding production targets and maintaining highquality standards.

- Awarded Safety Excellence Certificate for maintaining a safe and compliant work environment.

- Recognized for Innovation in Die Molding for developing a novel approach to mold design.

Certificates

- Certified Molding Technician (CMT)

- Certified Plastics Technician (CPT)

- Certified Quality Technician (CQT)

- Certified Six Sigma Green Belt

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Lead Die Molder

- Showcase your technical skills and expertise in die molding processes, press operation, and mold maintenance.

- Highlight your leadership and management abilities, including your experience in supervising and motivating a team.

- Quantify your accomplishments whenever possible, providing specific metrics and results that demonstrate your impact on the organization.

- Emphasize your commitment to quality and safety, and provide examples of how you have implemented and maintained high standards in your previous roles.

Essential Experience Highlights for a Strong Lead Die Molder Resume

- Supervise and manage a team of die molders, providing guidance and training to ensure efficient and productive operations.

- Set up and operate die molding presses, ensuring proper mold alignment, pressure, and temperature settings.

- Conduct preventive maintenance and repairs on molds, presses, and other equipment to minimize downtime and ensure optimal performance.

- Optimize molding processes to improve cycle times, reduce scrap, and enhance product quality.

- Establish and maintain quality control procedures to ensure that products meet specifications and customer requirements.

- Manage material handling and inventory to ensure a continuous supply of raw materials and timely delivery of finished products.

- Enforce safety regulations and ensure compliance with all applicable industry standards and regulations.

Frequently Asked Questions (FAQ’s) For Lead Die Molder

What are the key skills required to be a successful Lead Die Molder?

The key skills required to be a successful Lead Die Molder include strong technical expertise in die molding processes, press operation, mold maintenance, and quality control. Additionally, leadership and management skills, as well as a commitment to safety and continuous improvement, are essential.

What are the career prospects for Lead Die Molders?

Lead Die Molders are in high demand due to the increasing use of plastic products in various industries. With experience and expertise, Lead Die Molders can advance to management positions, such as Production Supervisor or Plant Manager. They can also specialize in specific areas, such as mold design or process engineering.

What is the work environment like for Lead Die Molders?

Lead Die Molders typically work in manufacturing facilities, operating die molding presses and performing maintenance tasks. The work environment can be fast-paced and demanding, requiring attention to detail and a strong commitment to safety. However, it also offers opportunities for hands-on experience and the satisfaction of producing high-quality products.

What are the educational requirements for becoming a Lead Die Molder?

While some Lead Die Molders may have a high school diploma or equivalent, most employers prefer candidates with an associate’s degree in a related field, such as tool and die making or plastics technology. Additional training and certifications in die molding processes and equipment are also beneficial.

What are the earning prospects for Lead Die Molders?

The earning potential for Lead Die Molders can vary depending on their experience, skills, and location. According to the U.S. Bureau of Labor Statistics, the median annual salary for Molding and Casting Workers, which includes Lead Die Molders, was $43,500 in May 2021. However, experienced Lead Die Molders with specialized skills can earn significantly more.

Is there a high demand for Lead Die Molders?

Yes, there is a high demand for Lead Die Molders due to the increasing use of plastic products in various industries, such as automotive, electronics, and construction. The aging workforce and the need for skilled workers to operate and maintain advanced molding equipment further contribute to the demand.

What are the opportunities for career growth for Lead Die Molders?

Lead Die Molders can advance their careers by developing specialized skills in areas such as mold design, process engineering, or quality management. They may move into supervisory or management positions, such as Production Supervisor or Plant Manager. Additionally, some Lead Die Molders start their own businesses, providing molding services or manufacturing plastic products.

What are the working conditions like for Lead Die Molders?

Lead Die Molders typically work in manufacturing facilities, operating die molding presses and performing maintenance tasks. The work can be physically demanding, requiring prolonged standing, lifting heavy objects, and working in noisy and potentially hazardous environments. However, many modern manufacturing facilities are well-equipped with safety measures and ergonomic equipment to minimize risks.