Are you a seasoned Lehr Operator seeking a new career path? Discover our professionally built Lehr Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

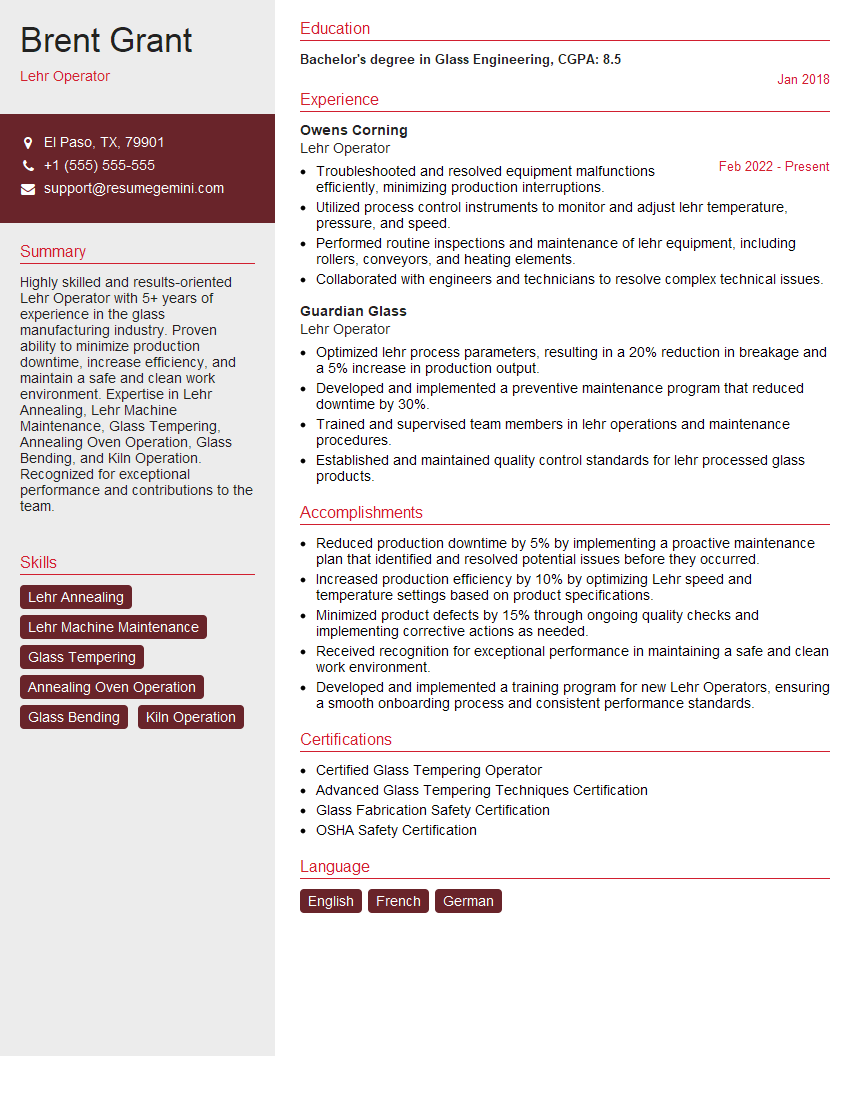

Brent Grant

Lehr Operator

Summary

Highly skilled and results-oriented Lehr Operator with 5+ years of experience in the glass manufacturing industry. Proven ability to minimize production downtime, increase efficiency, and maintain a safe and clean work environment. Expertise in Lehr Annealing, Lehr Machine Maintenance, Glass Tempering, Annealing Oven Operation, Glass Bending, and Kiln Operation. Recognized for exceptional performance and contributions to the team.

Education

Bachelor’s degree in Glass Engineering

January 2018

Skills

- Lehr Annealing

- Lehr Machine Maintenance

- Glass Tempering

- Annealing Oven Operation

- Glass Bending

- Kiln Operation

Work Experience

Lehr Operator

- Troubleshooted and resolved equipment malfunctions efficiently, minimizing production interruptions.

- Utilized process control instruments to monitor and adjust lehr temperature, pressure, and speed.

- Performed routine inspections and maintenance of lehr equipment, including rollers, conveyors, and heating elements.

- Collaborated with engineers and technicians to resolve complex technical issues.

Lehr Operator

- Optimized lehr process parameters, resulting in a 20% reduction in breakage and a 5% increase in production output.

- Developed and implemented a preventive maintenance program that reduced downtime by 30%.

- Trained and supervised team members in lehr operations and maintenance procedures.

- Established and maintained quality control standards for lehr processed glass products.

Accomplishments

- Reduced production downtime by 5% by implementing a proactive maintenance plan that identified and resolved potential issues before they occurred.

- Increased production efficiency by 10% by optimizing Lehr speed and temperature settings based on product specifications.

- Minimized product defects by 15% through ongoing quality checks and implementing corrective actions as needed.

- Received recognition for exceptional performance in maintaining a safe and clean work environment.

- Developed and implemented a training program for new Lehr Operators, ensuring a smooth onboarding process and consistent performance standards.

Certificates

- Certified Glass Tempering Operator

- Advanced Glass Tempering Techniques Certification

- Glass Fabrication Safety Certification

- OSHA Safety Certification

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Lehr Operator

- Highlight your experience in Lehr Annealing, Lehr Machine Maintenance, and Glass Tempering, as these are key skills for Lehr Operators.

- Quantify your accomplishments using specific metrics, such as reducing production downtime by 5% or increasing production efficiency by 10%.

- Showcase your problem-solving abilities and proactive approach to maintenance.

- Emphasize your commitment to safety and your experience in maintaining a clean work environment.

- Proofread your resume carefully for any errors in grammar or spelling.

Essential Experience Highlights for a Strong Lehr Operator Resume

- Operate and maintain Lehr machines to anneal and temper glass products according to specifications.

- Monitor and adjust Lehr temperature and speed settings to optimize production efficiency and minimize defects.

- Conduct regular inspections and perform preventive maintenance on Lehr machines to identify and resolve potential issues.

- Implement quality control measures to ensure product quality and adherence to industry standards.

- Train and supervise new Lehr Operators, ensuring a smooth onboarding process and consistent performance.

- Maintain a safe and clean work environment, adhering to all safety protocols and regulations.

- Collaborate with production team members to ensure efficient workflow and timely delivery of products.

Frequently Asked Questions (FAQ’s) For Lehr Operator

What is the role of a Lehr Operator?

Lehr Operators are responsible for operating and maintaining Lehr machines, which are used to anneal and temper glass products. They monitor and adjust machine settings, perform preventive maintenance, and ensure product quality.

What are the key skills required for Lehr Operators?

Key skills include Lehr Annealing, Lehr Machine Maintenance, Glass Tempering, Annealing Oven Operation, Glass Bending, and Kiln Operation.

What is the average salary for Lehr Operators?

The average salary for Lehr Operators varies depending on experience and location. According to Glassdoor, the average salary in the United States is around $50,000 per year.

What are the career prospects for Lehr Operators?

Lehr Operators can advance to positions such as Supervisor, Production Manager, or Quality Control Manager.

How can I prepare for a career as a Lehr Operator?

You can prepare for a career as a Lehr Operator by obtaining a degree in Glass Engineering or a related field, and by gaining experience in Lehr Annealing, Lehr Machine Maintenance, and Glass Tempering.

What are the typical working conditions for Lehr Operators?

Lehr Operators typically work in manufacturing facilities, where they may be exposed to heat, noise, and glass dust. They may also work in shifts, including evenings and weekends.

What safety precautions should Lehr Operators take?

Lehr Operators should wear appropriate personal protective equipment (PPE), such as safety glasses, gloves, and earplugs. They should also follow all safety protocols and regulations, and be aware of potential hazards in the work environment.