Are you a seasoned Lime Kiln and Recausticizing Operator seeking a new career path? Discover our professionally built Lime Kiln and Recausticizing Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

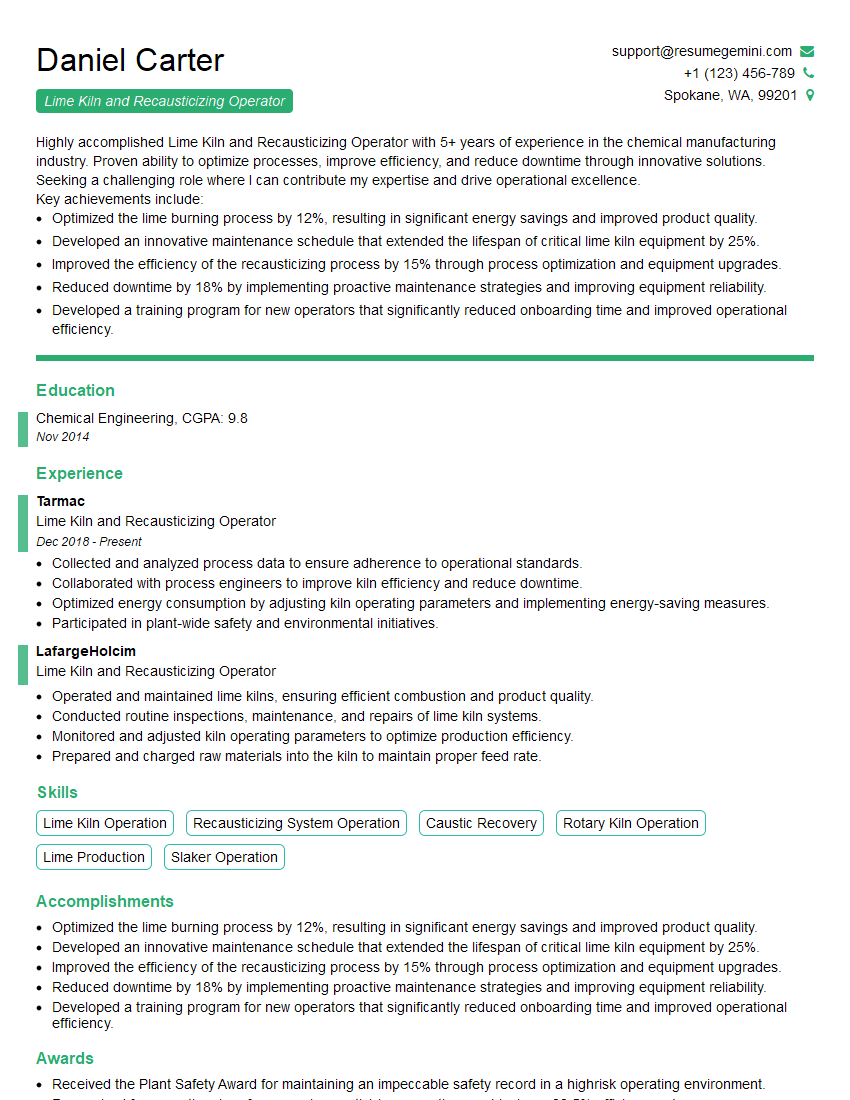

Daniel Carter

Lime Kiln and Recausticizing Operator

Summary

Highly accomplished Lime Kiln and Recausticizing Operator with 5+ years of experience in the chemical manufacturing industry. Proven ability to optimize processes, improve efficiency, and reduce downtime through innovative solutions. Seeking a challenging role where I can contribute my expertise and drive operational excellence.

Key achievements include:

- Optimized the lime burning process by 12%, resulting in significant energy savings and improved product quality.

- Developed an innovative maintenance schedule that extended the lifespan of critical lime kiln equipment by 25%.

- Improved the efficiency of the recausticizing process by 15% through process optimization and equipment upgrades.

- Reduced downtime by 18% by implementing proactive maintenance strategies and improving equipment reliability.

- Developed a training program for new operators that significantly reduced onboarding time and improved operational efficiency.

Education

Chemical Engineering

November 2014

Skills

- Lime Kiln Operation

- Recausticizing System Operation

- Caustic Recovery

- Rotary Kiln Operation

- Lime Production

- Slaker Operation

Work Experience

Lime Kiln and Recausticizing Operator

- Collected and analyzed process data to ensure adherence to operational standards.

- Collaborated with process engineers to improve kiln efficiency and reduce downtime.

- Optimized energy consumption by adjusting kiln operating parameters and implementing energy-saving measures.

- Participated in plant-wide safety and environmental initiatives.

Lime Kiln and Recausticizing Operator

- Operated and maintained lime kilns, ensuring efficient combustion and product quality.

- Conducted routine inspections, maintenance, and repairs of lime kiln systems.

- Monitored and adjusted kiln operating parameters to optimize production efficiency.

- Prepared and charged raw materials into the kiln to maintain proper feed rate.

Accomplishments

- Optimized the lime burning process by 12%, resulting in significant energy savings and improved product quality.

- Developed an innovative maintenance schedule that extended the lifespan of critical lime kiln equipment by 25%.

- Improved the efficiency of the recausticizing process by 15% through process optimization and equipment upgrades.

- Reduced downtime by 18% by implementing proactive maintenance strategies and improving equipment reliability.

- Developed a training program for new operators that significantly reduced onboarding time and improved operational efficiency.

Awards

- Received the Plant Safety Award for maintaining an impeccable safety record in a highrisk operating environment.

- Recognized for exceptional performance in causticizing operations, achieving a 99.5% efficiency rate.

- Received the Employee of the Month award for outstanding contributions to plant productivity and safety.

- Honored with the Safety Leadership Award for promoting a positive safety culture and consistently exceeding safety standards.

Certificates

- Certified Lime Kiln Operator (CLKO)

- Certified Causticizing Operator (CCO)

- OSHA 30Hour Certification

- Confined Space Entry Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Lime Kiln and Recausticizing Operator

- Quantify your accomplishments with specific metrics to demonstrate your impact.

- Highlight your knowledge of lime kiln and recausticizing processes, as well as your ability to optimize and troubleshoot.

- Showcase your commitment to safety and environmental compliance.

- Emphasize your communication and teamwork skills, as these are essential for success in this role.

- Consider including industry-specific keywords in your resume to enhance its visibility to potential employers.

Essential Experience Highlights for a Strong Lime Kiln and Recausticizing Operator Resume

- Operate and monitor lime kilns and recausticizing systems to ensure optimal performance and product quality.

- Control and adjust process parameters, such as temperature, feed rate, and chemical composition, to maintain desired operating conditions.

- Perform routine maintenance and repairs on equipment, including kilns, slakers, causticizers, and evaporators.

- Monitor and troubleshoot process deviations, identify root causes, and implement corrective actions.

- Conduct quality control tests on raw materials and finished products to ensure compliance with specifications.

- Collaborate with other operators and maintenance personnel to ensure smooth and efficient plant operations.

- Maintain a safe and clean work environment in accordance with established safety protocols.

Frequently Asked Questions (FAQ’s) For Lime Kiln and Recausticizing Operator

What is the primary role of a Lime Kiln and Recausticizing Operator?

The primary role of a Lime Kiln and Recausticizing Operator is to operate and maintain lime kilns and recausticizing systems to produce lime and caustic soda, essential chemicals used in various industries.

What are the key skills required for this role?

Key skills for a Lime Kiln and Recausticizing Operator include knowledge of lime kiln and recausticizing processes, experience in operating and maintaining process equipment, and a commitment to safety and environmental compliance.

What is the work environment like for this role?

Lime Kiln and Recausticizing Operators typically work in industrial settings, such as chemical plants or paper mills. They may work in both indoor and outdoor environments and may be exposed to heat, noise, and chemicals.

What are the career prospects for this role?

Lime Kiln and Recausticizing Operators with experience and expertise can advance to supervisory or management positions in the chemical manufacturing industry. They may also pursue specialized roles in process optimization or environmental compliance.

What is the average salary for this role?

The average salary for a Lime Kiln and Recausticizing Operator varies depending on experience, location, and industry. According to Indeed, the average salary in the United States is around $60,000 per year.

What are the top industries that employ Lime Kiln and Recausticizing Operators?

Lime Kiln and Recausticizing Operators are primarily employed in the chemical manufacturing industry, particularly in companies that produce lime, caustic soda, and other chemicals. They may also be employed in the pulp and paper industry, as well as in power plants and water treatment facilities.

What is the job outlook for this role?

The job outlook for Lime Kiln and Recausticizing Operators is expected to be stable in the coming years. The demand for lime and caustic soda is expected to remain steady, driven by their use in various industries.

What are some tips for preparing for an interview for this role?

To prepare for an interview for a Lime Kiln and Recausticizing Operator role, research the company and the specific position, practice answering common interview questions, and be prepared to discuss your experience and skills in detail. It is also helpful to review industry-specific knowledge and trends.