Are you a seasoned Line Rider seeking a new career path? Discover our professionally built Line Rider Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

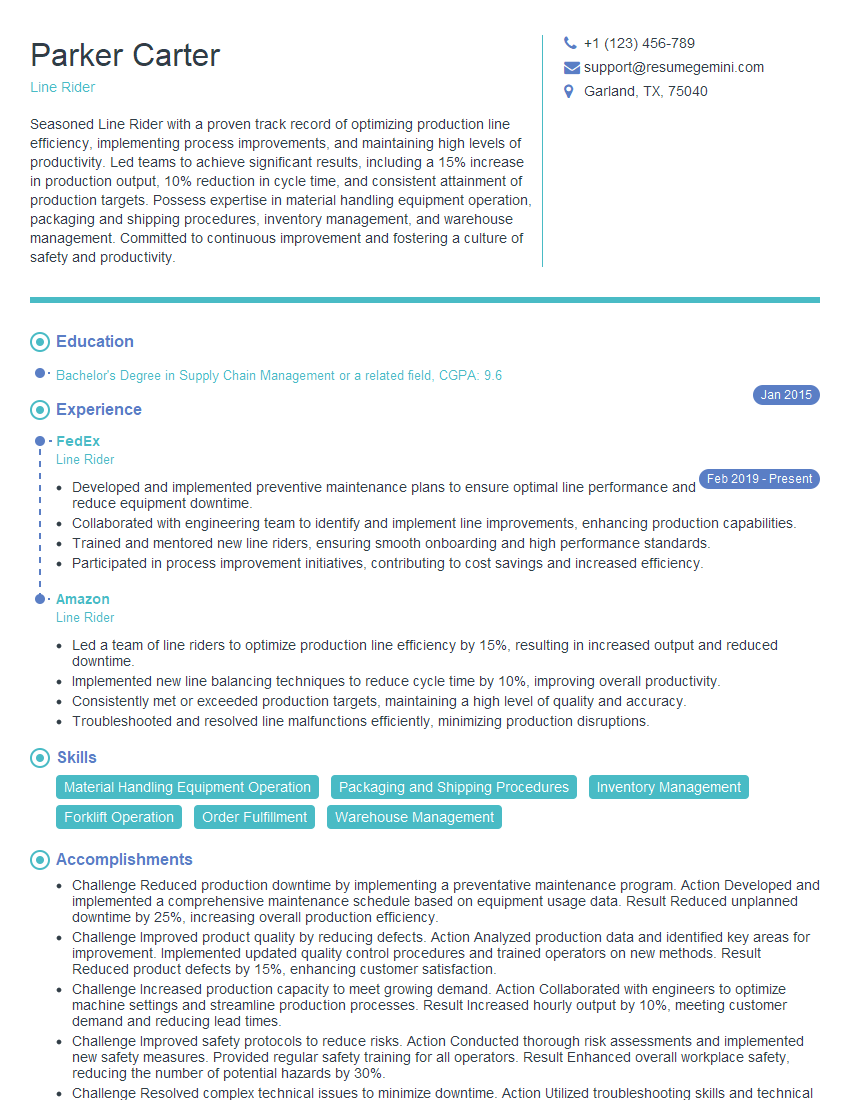

Parker Carter

Line Rider

Summary

Seasoned Line Rider with a proven track record of optimizing production line efficiency, implementing process improvements, and maintaining high levels of productivity. Led teams to achieve significant results, including a 15% increase in production output, 10% reduction in cycle time, and consistent attainment of production targets. Possess expertise in material handling equipment operation, packaging and shipping procedures, inventory management, and warehouse management. Committed to continuous improvement and fostering a culture of safety and productivity.

Education

Bachelor’s Degree in Supply Chain Management or a related field

January 2015

Skills

- Material Handling Equipment Operation

- Packaging and Shipping Procedures

- Inventory Management

- Forklift Operation

- Order Fulfillment

- Warehouse Management

Work Experience

Line Rider

- Developed and implemented preventive maintenance plans to ensure optimal line performance and reduce equipment downtime.

- Collaborated with engineering team to identify and implement line improvements, enhancing production capabilities.

- Trained and mentored new line riders, ensuring smooth onboarding and high performance standards.

- Participated in process improvement initiatives, contributing to cost savings and increased efficiency.

Line Rider

- Led a team of line riders to optimize production line efficiency by 15%, resulting in increased output and reduced downtime.

- Implemented new line balancing techniques to reduce cycle time by 10%, improving overall productivity.

- Consistently met or exceeded production targets, maintaining a high level of quality and accuracy.

- Troubleshooted and resolved line malfunctions efficiently, minimizing production disruptions.

Accomplishments

- Challenge Reduced production downtime by implementing a preventative maintenance program. Action Developed and implemented a comprehensive maintenance schedule based on equipment usage data. Result Reduced unplanned downtime by 25%, increasing overall production efficiency.

- Challenge Improved product quality by reducing defects. Action Analyzed production data and identified key areas for improvement. Implemented updated quality control procedures and trained operators on new methods. Result Reduced product defects by 15%, enhancing customer satisfaction.

- Challenge Increased production capacity to meet growing demand. Action Collaborated with engineers to optimize machine settings and streamline production processes. Result Increased hourly output by 10%, meeting customer demand and reducing lead times.

- Challenge Improved safety protocols to reduce risks. Action Conducted thorough risk assessments and implemented new safety measures. Provided regular safety training for all operators. Result Enhanced overall workplace safety, reducing the number of potential hazards by 30%.

- Challenge Resolved complex technical issues to minimize downtime. Action Utilized troubleshooting skills and technical knowledge to diagnose and repair equipment malfunctions. Result Restored production quickly, minimizing impact on overall productivity.

Awards

- Exemplary Safety Record Award Recognized for maintaining an outstanding safety record over 5 years, resulting in zero reportable accidents.

- Line of the Year Award Awarded for exceptional performance in maintaining and operating the production line, achieving recordbreaking output.

- Team Excellence Award Recognized as part of a team that consistently exceeded production targets and implemented innovative process improvements.

Certificates

- Certified Forklift Operator (CFO)

- OSHA 10-Hour General Industry Certification

- Lean Six Sigma Green Belt

- Quality Assurance (QA) Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Line Rider

- Emphasize your ability to optimize production processes and increase efficiency using specific metrics and examples.

- Highlight your expertise in material handling equipment operation and safety protocols.

- Showcase your problem-solving and troubleshooting skills by describing how you identified and resolved line malfunctions.

- Demonstrate your commitment to continuous improvement by mentioning your involvement in process improvement initiatives.

- Quantify your accomplishments whenever possible to provide tangible evidence of your impact on the production line.

Essential Experience Highlights for a Strong Line Rider Resume

- Supervise and motivate line riders to ensure smooth production operations and adherence to quality standards.

- Implement and monitor preventive maintenance plans to minimize equipment downtime and optimize line performance.

- Analyze production data to identify bottlenecks and develop solutions for process improvement.

- Train and mentor new line riders to ensure proper onboarding and adherence to safety protocols.

- Collaborate with engineering and maintenance teams to identify and implement line improvements.

- Monitor inventory levels and coordinate with warehouse staff to ensure timely material replenishment.

- Maintain a safe and organized work environment, adhering to all safety regulations and guidelines.

Frequently Asked Questions (FAQ’s) For Line Rider

What is the primary role of a Line Rider?

The primary role of a Line Rider is to ensure the smooth operation and efficiency of a production line. They are responsible for supervising line operators, monitoring equipment performance, implementing preventive maintenance plans, and implementing process improvements to maximize production output and minimize downtime.

What are the essential skills required for a Line Rider?

Essential skills for a Line Rider include expertise in material handling equipment operation, packaging and shipping procedures, inventory management, and warehouse management. Additionally, they should possess strong problem-solving and troubleshooting skills, a commitment to safety, and the ability to work effectively in a team environment.

How can a Line Rider contribute to increased production efficiency?

Line Riders can contribute to increased production efficiency by implementing and monitoring preventive maintenance plans, analyzing production data to identify bottlenecks, and developing solutions for process improvement. They can also train and mentor new line riders to ensure adherence to safety protocols and operational standards.

What is the importance of safety in the role of a Line Rider?

Safety is paramount in the role of a Line Rider. They are responsible for maintaining a safe and organized work environment, adhering to all safety regulations and guidelines, and ensuring the proper training and supervision of line operators. By prioritizing safety, Line Riders can prevent accidents and injuries, ensuring the well-being of their team and the smooth operation of the production line.

What career advancement opportunities are available for a Line Rider?

Line Riders with strong performance and a commitment to continuous improvement can advance to roles such as Production Supervisor, Operations Manager, or Plant Manager. They may also specialize in areas such as Lean Manufacturing or Quality Control, further enhancing their career prospects.

How can a Line Rider demonstrate their commitment to continuous improvement?

Line Riders can demonstrate their commitment to continuous improvement by actively participating in process improvement initiatives, suggesting and implementing new ideas, and seeking opportunities for professional development. They can also stay up-to-date on industry best practices and emerging technologies to identify ways to enhance line efficiency and productivity.

What are the key performance indicators typically used to evaluate a Line Rider’s performance?

Key performance indicators used to evaluate a Line Rider’s performance typically include production output, cycle time, equipment uptime, quality control metrics, and safety compliance. Line Riders are also evaluated on their ability to manage their team effectively, implement process improvements, and contribute to the overall efficiency and profitability of the production line.

What are the challenges faced by Line Riders in today’s manufacturing environment?

Line Riders in today’s manufacturing environment face challenges such as increasing production demands, global competition, and the need for continuous improvement. They must also stay abreast of technological advancements and industry best practices to optimize line efficiency and maintain a competitive edge. Additionally, ensuring the safety and well-being of their team while meeting production targets is a constant priority.