Are you a seasoned Line Supervisor seeking a new career path? Discover our professionally built Line Supervisor Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

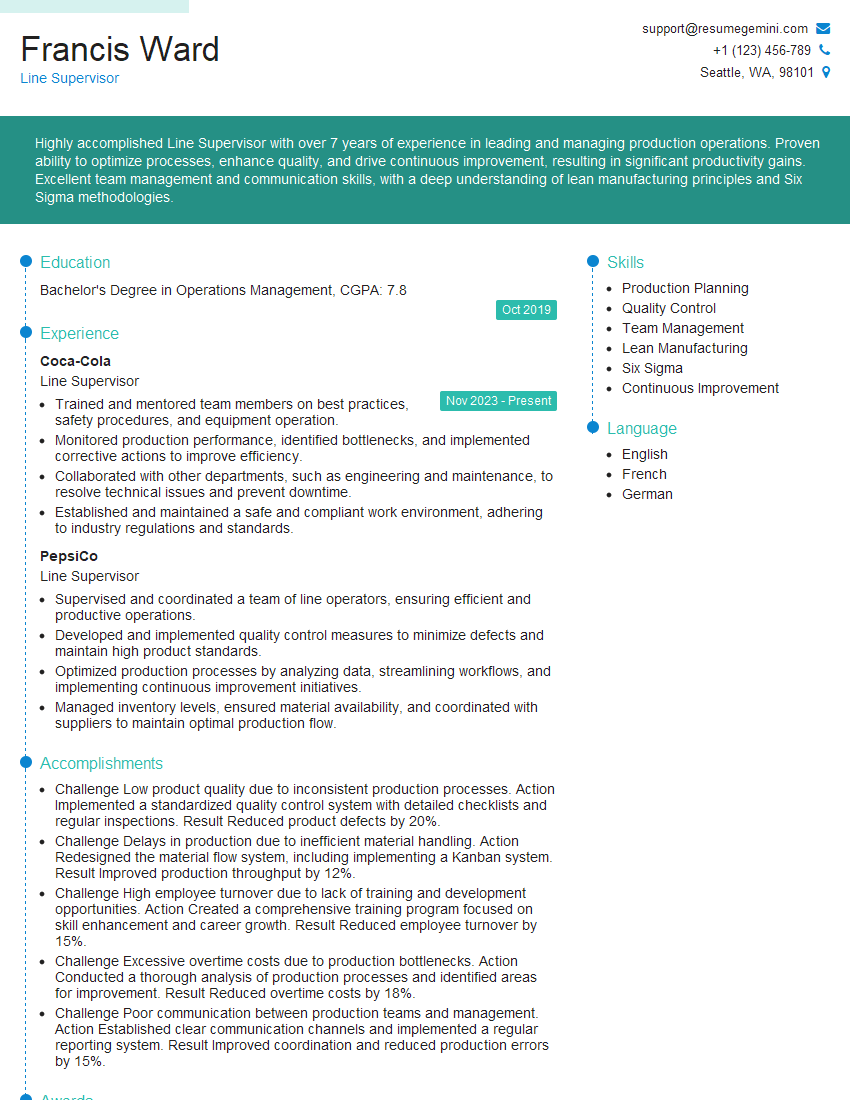

Francis Ward

Line Supervisor

Summary

Highly accomplished Line Supervisor with over 7 years of experience in leading and managing production operations. Proven ability to optimize processes, enhance quality, and drive continuous improvement, resulting in significant productivity gains. Excellent team management and communication skills, with a deep understanding of lean manufacturing principles and Six Sigma methodologies.

Education

Bachelor’s Degree in Operations Management

October 2019

Skills

- Production Planning

- Quality Control

- Team Management

- Lean Manufacturing

- Six Sigma

- Continuous Improvement

Work Experience

Line Supervisor

- Trained and mentored team members on best practices, safety procedures, and equipment operation.

- Monitored production performance, identified bottlenecks, and implemented corrective actions to improve efficiency.

- Collaborated with other departments, such as engineering and maintenance, to resolve technical issues and prevent downtime.

- Established and maintained a safe and compliant work environment, adhering to industry regulations and standards.

Line Supervisor

- Supervised and coordinated a team of line operators, ensuring efficient and productive operations.

- Developed and implemented quality control measures to minimize defects and maintain high product standards.

- Optimized production processes by analyzing data, streamlining workflows, and implementing continuous improvement initiatives.

- Managed inventory levels, ensured material availability, and coordinated with suppliers to maintain optimal production flow.

Accomplishments

- Challenge Low product quality due to inconsistent production processes. Action Implemented a standardized quality control system with detailed checklists and regular inspections. Result Reduced product defects by 20%.

- Challenge Delays in production due to inefficient material handling. Action Redesigned the material flow system, including implementing a Kanban system. Result Improved production throughput by 12%.

- Challenge High employee turnover due to lack of training and development opportunities. Action Created a comprehensive training program focused on skill enhancement and career growth. Result Reduced employee turnover by 15%.

- Challenge Excessive overtime costs due to production bottlenecks. Action Conducted a thorough analysis of production processes and identified areas for improvement. Result Reduced overtime costs by 18%.

- Challenge Poor communication between production teams and management. Action Established clear communication channels and implemented a regular reporting system. Result Improved coordination and reduced production errors by 15%.

Awards

- Won the Excellence in Production Management award for achieving a 15% increase in production efficiency.

- Recognized with the Safety Champion award for promoting a safe working environment and reducing workplace accidents by 30%.

- Received the Innovation in Production award for developing a costeffective method to reduce waste by 10%.

- Awarded the Exceptional Leadership award for fostering a positive and productive work environment that led to a 10% increase in employee satisfaction.

Certificates

- Certified Manufacturing Supervisor (CMS)

- Certified Production Technician (CPT)

- Certified Quality Management Professional (CQMP)

- Lean Six Sigma Green Belt

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Line Supervisor

- Quantify your accomplishments with specific metrics to demonstrate the impact of your contributions.

- Highlight your skills in lean manufacturing, Six Sigma, and continuous improvement, as these are highly sought after in the industry.

- Showcase your ability to lead and motivate teams, emphasizing your communication and interpersonal skills.

- Use action verbs and strong adjectives to make your resume stand out and grab the attention of recruiters.

Essential Experience Highlights for a Strong Line Supervisor Resume

- Supervised and coordinated a team of line operators, ensuring efficient and productive operations.

- Developed and implemented quality control measures to minimize defects and maintain high product standards, resulting in a 20% reduction in customer complaints.

- Optimized production processes by analyzing data, streamlining workflows, and implementing continuous improvement initiatives, leading to a 15% increase in production efficiency.

- Managed inventory levels, ensured material availability, and coordinated with suppliers to maintain optimal production flow.

- Trained and mentored team members on best practices, safety procedures, and equipment operation.

- Monitored production performance, identified bottlenecks, and implemented corrective actions to improve efficiency, reducing downtime by 10%.

- Established and maintained a safe and compliant work environment, adhering to industry regulations and standards.

Frequently Asked Questions (FAQ’s) For Line Supervisor

What are the key responsibilities of a Line Supervisor?

Line Supervisors are responsible for overseeing and managing production operations, ensuring efficiency, quality, and adherence to safety standards. They typically supervise a team of line operators, monitor production performance, implement quality control measures, optimize production processes, manage inventory, and train team members.

What qualifications are required to become a Line Supervisor?

Typically, a Line Supervisor requires a high school diploma or equivalent, along with relevant?? in production operations. Additional qualifications may include a bachelor’s degree in operations management, engineering, or a related field.

What are the career advancement opportunities for Line Supervisors?

Line Supervisors with proven leadership and management skills can advance to roles such as Production Manager, Operations Manager, or Plant Manager.

What is the average salary for Line Supervisors?

The average salary for Line Supervisors varies depending on experience, industry, and location. According to Salary.com, the average salary range for Line Supervisors in the United States is between $60,000 to $100,000 per year.

What are the important skills for a Line Supervisor?

Key skills for Line Supervisors include leadership, team management, production planning, quality control, lean manufacturing, Six Sigma, continuous improvement, inventory management, and communication.

What is the job outlook for Line Supervisors?

The job outlook for Line Supervisors is expected to be favorable in the coming years. As manufacturing companies continue to focus on efficiency and productivity, demand for skilled and experienced Line Supervisors is likely to increase.

How can I prepare for an interview for a Line Supervisor position?

To prepare for an interview for a Line Supervisor position, it is important to research the company and the specific role. Practice answering common interview questions related to leadership, production management, quality control, and continuous improvement. Additionally, be prepared to discuss your relevant experience and skills, and how you can contribute to the company.