Are you a seasoned Lining Mechanic seeking a new career path? Discover our professionally built Lining Mechanic Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

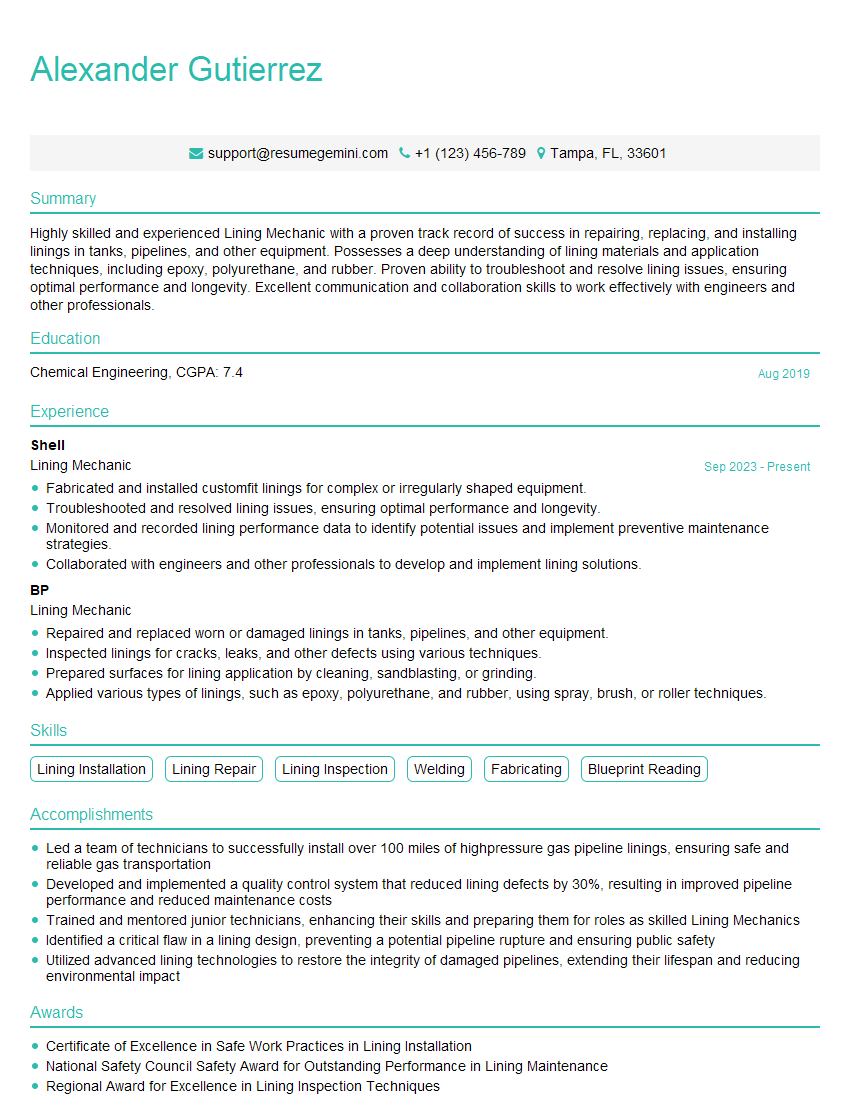

Alexander Gutierrez

Lining Mechanic

Summary

Highly skilled and experienced Lining Mechanic with a proven track record of success in repairing, replacing, and installing linings in tanks, pipelines, and other equipment. Possesses a deep understanding of lining materials and application techniques, including epoxy, polyurethane, and rubber. Proven ability to troubleshoot and resolve lining issues, ensuring optimal performance and longevity. Excellent communication and collaboration skills to work effectively with engineers and other professionals.

Education

Chemical Engineering

August 2019

Skills

- Lining Installation

- Lining Repair

- Lining Inspection

- Welding

- Fabricating

- Blueprint Reading

Work Experience

Lining Mechanic

- Fabricated and installed customfit linings for complex or irregularly shaped equipment.

- Troubleshooted and resolved lining issues, ensuring optimal performance and longevity.

- Monitored and recorded lining performance data to identify potential issues and implement preventive maintenance strategies.

- Collaborated with engineers and other professionals to develop and implement lining solutions.

Lining Mechanic

- Repaired and replaced worn or damaged linings in tanks, pipelines, and other equipment.

- Inspected linings for cracks, leaks, and other defects using various techniques.

- Prepared surfaces for lining application by cleaning, sandblasting, or grinding.

- Applied various types of linings, such as epoxy, polyurethane, and rubber, using spray, brush, or roller techniques.

Accomplishments

- Led a team of technicians to successfully install over 100 miles of highpressure gas pipeline linings, ensuring safe and reliable gas transportation

- Developed and implemented a quality control system that reduced lining defects by 30%, resulting in improved pipeline performance and reduced maintenance costs

- Trained and mentored junior technicians, enhancing their skills and preparing them for roles as skilled Lining Mechanics

- Identified a critical flaw in a lining design, preventing a potential pipeline rupture and ensuring public safety

- Utilized advanced lining technologies to restore the integrity of damaged pipelines, extending their lifespan and reducing environmental impact

Awards

- Certificate of Excellence in Safe Work Practices in Lining Installation

- National Safety Council Safety Award for Outstanding Performance in Lining Maintenance

- Regional Award for Excellence in Lining Inspection Techniques

Certificates

- Certified Welding Inspector (CWI)

- American Welding Society (AWS) Certified Welder

- National Association of Corrosion Engineers (NACE) Corrosion Specialist

- Occupational Safety and Health Administration (OSHA) 30-Hour Safety Training

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Lining Mechanic

- Highlight your experience and skills in lining installation, repair, and inspection.

- Showcase your ability to troubleshoot and resolve lining issues.

- Demonstrate your knowledge of lining materials and application techniques.

- Emphasize your ability to work independently and as part of a team.

Essential Experience Highlights for a Strong Lining Mechanic Resume

- Repaired and replaced worn or damaged linings in tanks, pipelines, and other equipment.

- Inspected linings for cracks, leaks, and other defects using various techniques.

- Prepared surfaces for lining application by cleaning, sandblasting, or grinding.

- Applied various types of linings, such as epoxy, polyurethane, and rubber, using spray, brush, or roller techniques.

- Fabricated and installed customfit linings for complex or irregularly shaped equipment.

- Troubleshooted and resolved lining issues, ensuring optimal performance and longevity.

- Monitored and recorded lining performance data to identify potential issues and implement preventive maintenance strategies.

Frequently Asked Questions (FAQ’s) For Lining Mechanic

What are the primary responsibilities of a Lining Mechanic?

The primary responsibilities of a Lining Mechanic include repairing, replacing, and installing linings in tanks, pipelines, and other equipment.

What skills are required to be a successful Lining Mechanic?

Successful Lining Mechanics typically have a strong understanding of lining materials and application techniques, as well as experience in troubleshooting and resolving lining issues.

What are the career prospects for Lining Mechanics?

Lining Mechanics with experience and expertise can advance to supervisory or management positions, or specialize in specific types of lining applications.

What industries employ Lining Mechanics?

Lining Mechanics are employed in a variety of industries, including oil and gas, chemical processing, and water treatment.

How can I improve my chances of getting hired as a Lining Mechanic?

To improve your chances of getting hired as a Lining Mechanic, focus on developing your skills and experience, and highlight your ability to work independently and as part of a team.

What are the key qualities of a successful Lining Mechanic?

Successful Lining Mechanics are typically detailoriented, have strong problem-solving skills, and are able to work independently and as part of a team.