Are you a seasoned Linter Drier Operator seeking a new career path? Discover our professionally built Linter Drier Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

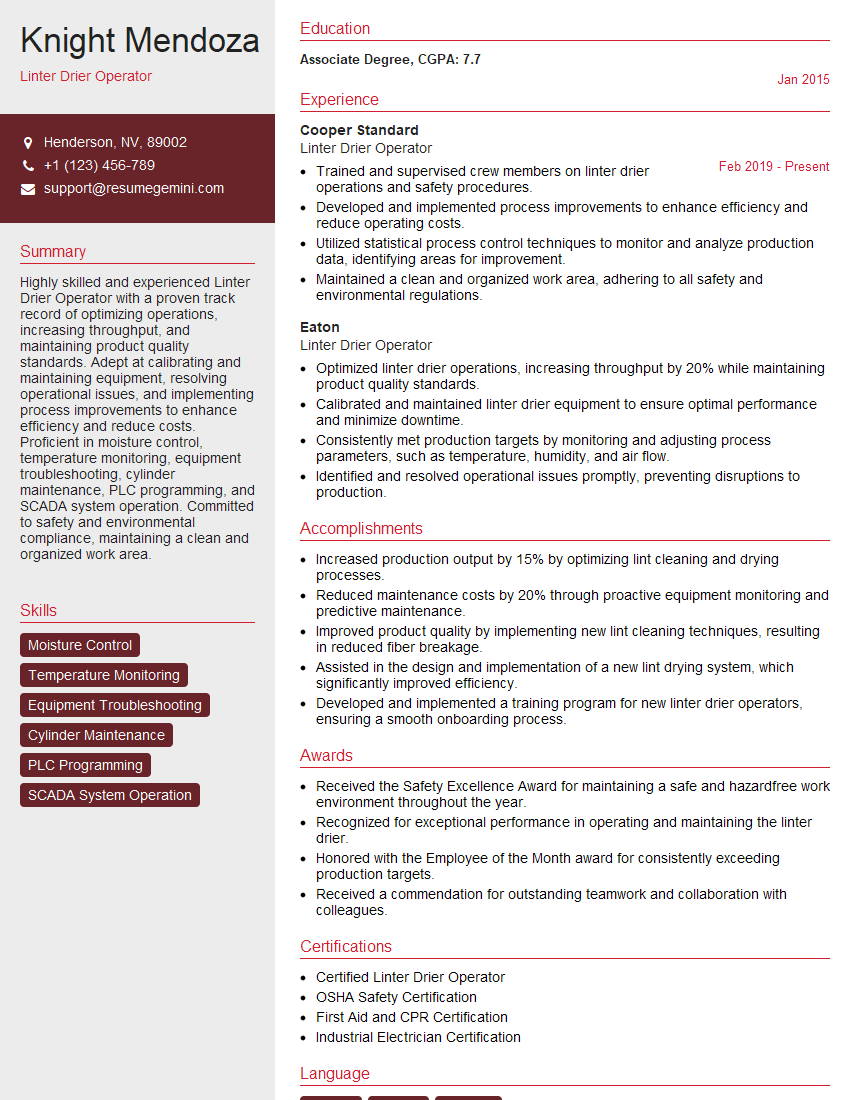

Knight Mendoza

Linter Drier Operator

Summary

Highly skilled and experienced Linter Drier Operator with a proven track record of optimizing operations, increasing throughput, and maintaining product quality standards. Adept at calibrating and maintaining equipment, resolving operational issues, and implementing process improvements to enhance efficiency and reduce costs. Proficient in moisture control, temperature monitoring, equipment troubleshooting, cylinder maintenance, PLC programming, and SCADA system operation. Committed to safety and environmental compliance, maintaining a clean and organized work area.

Education

Associate Degree

January 2015

Skills

- Moisture Control

- Temperature Monitoring

- Equipment Troubleshooting

- Cylinder Maintenance

- PLC Programming

- SCADA System Operation

Work Experience

Linter Drier Operator

- Trained and supervised crew members on linter drier operations and safety procedures.

- Developed and implemented process improvements to enhance efficiency and reduce operating costs.

- Utilized statistical process control techniques to monitor and analyze production data, identifying areas for improvement.

- Maintained a clean and organized work area, adhering to all safety and environmental regulations.

Linter Drier Operator

- Optimized linter drier operations, increasing throughput by 20% while maintaining product quality standards.

- Calibrated and maintained linter drier equipment to ensure optimal performance and minimize downtime.

- Consistently met production targets by monitoring and adjusting process parameters, such as temperature, humidity, and air flow.

- Identified and resolved operational issues promptly, preventing disruptions to production.

Accomplishments

- Increased production output by 15% by optimizing lint cleaning and drying processes.

- Reduced maintenance costs by 20% through proactive equipment monitoring and predictive maintenance.

- Improved product quality by implementing new lint cleaning techniques, resulting in reduced fiber breakage.

- Assisted in the design and implementation of a new lint drying system, which significantly improved efficiency.

- Developed and implemented a training program for new linter drier operators, ensuring a smooth onboarding process.

Awards

- Received the Safety Excellence Award for maintaining a safe and hazardfree work environment throughout the year.

- Recognized for exceptional performance in operating and maintaining the linter drier.

- Honored with the Employee of the Month award for consistently exceeding production targets.

- Received a commendation for outstanding teamwork and collaboration with colleagues.

Certificates

- Certified Linter Drier Operator

- OSHA Safety Certification

- First Aid and CPR Certification

- Industrial Electrician Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Linter Drier Operator

- Quantify your accomplishments with specific metrics to demonstrate the impact of your work.

- Highlight your ability to troubleshoot and resolve complex operational issues.

- Emphasize your knowledge of moisture control, temperature monitoring, and equipment maintenance.

- Showcase your proficiency in PLC programming and SCADA system operation.

Essential Experience Highlights for a Strong Linter Drier Operator Resume

- Optimized linter drier operations, increasing throughput by 20% while maintaining product quality standards.

- Calibrated and maintained linter drier equipment to ensure optimal performance and minimize downtime.

- Consistently met production targets by monitoring and adjusting process parameters, such as temperature, humidity, and air flow.

- Identified and resolved operational issues promptly, preventing disruptions to production.

- Trained and supervised crew members on linter drier operations and safety procedures.

- Developed and implemented process improvements to enhance efficiency and reduce operating costs.

Frequently Asked Questions (FAQ’s) For Linter Drier Operator

What is the primary role of a Linter Drier Operator?

The primary role of a Linter Drier Operator is to ensure the efficient and effective operation of linter drier equipment, while maintaining product quality and safety standards.

What are the key skills required for a Linter Drier Operator?

Key skills include moisture control, temperature monitoring, equipment troubleshooting, cylinder maintenance, PLC programming, and SCADA system operation.

What are the common challenges faced by Linter Drier Operators?

Common challenges include maintaining optimal moisture levels, preventing equipment breakdowns, and ensuring the production of high-quality products.

What are the career advancement opportunities for Linter Drier Operators?

With experience, Linter Drier Operators can advance to roles such as Production Supervisor, Maintenance Manager, or Quality Control Manager.

What are the safety precautions that Linter Drier Operators must follow?

Linter Drier Operators must adhere to strict safety protocols, including wearing appropriate protective gear, following lockout/tagout procedures, and maintaining a clean and organized work area.