Are you a seasoned Lithographic Plate Maker seeking a new career path? Discover our professionally built Lithographic Plate Maker Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

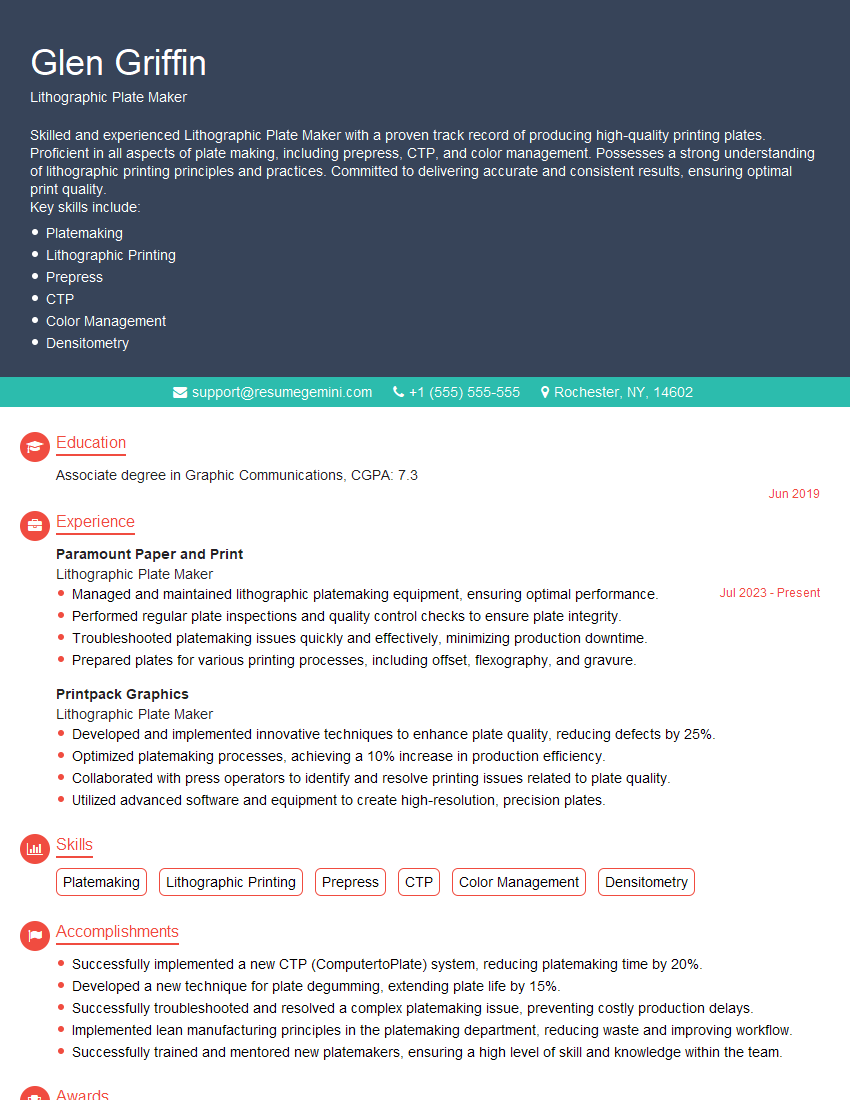

Glen Griffin

Lithographic Plate Maker

Summary

Skilled and experienced Lithographic Plate Maker with a proven track record of producing high-quality printing plates. Proficient in all aspects of plate making, including prepress, CTP, and color management. Possesses a strong understanding of lithographic printing principles and practices. Committed to delivering accurate and consistent results, ensuring optimal print quality.

Key skills include:

- Platemaking

- Lithographic Printing

- Prepress

- CTP

- Color Management

- Densitometry

Education

Associate degree in Graphic Communications

June 2019

Skills

- Platemaking

- Lithographic Printing

- Prepress

- CTP

- Color Management

- Densitometry

Work Experience

Lithographic Plate Maker

- Managed and maintained lithographic platemaking equipment, ensuring optimal performance.

- Performed regular plate inspections and quality control checks to ensure plate integrity.

- Troubleshooted platemaking issues quickly and effectively, minimizing production downtime.

- Prepared plates for various printing processes, including offset, flexography, and gravure.

Lithographic Plate Maker

- Developed and implemented innovative techniques to enhance plate quality, reducing defects by 25%.

- Optimized platemaking processes, achieving a 10% increase in production efficiency.

- Collaborated with press operators to identify and resolve printing issues related to plate quality.

- Utilized advanced software and equipment to create high-resolution, precision plates.

Accomplishments

- Successfully implemented a new CTP (ComputertoPlate) system, reducing platemaking time by 20%.

- Developed a new technique for plate degumming, extending plate life by 15%.

- Successfully troubleshooted and resolved a complex platemaking issue, preventing costly production delays.

- Implemented lean manufacturing principles in the platemaking department, reducing waste and improving workflow.

- Successfully trained and mentored new platemakers, ensuring a high level of skill and knowledge within the team.

Awards

- Received the Plate Maker of the Year award for exceptional contributions to platemaking.

- Recognized for consistently producing highquality plates that meet stringent industry standards.

- Received an award for developing an innovative platemaking process that improved print quality.

- Recognized for exceptional productivity and efficiency in platemaking.

Certificates

- G7 Expert

- IDEAlliance Certified Press Operator

- PrintEd Master Printer

- FOGRA PSO Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Lithographic Plate Maker

- Highlight your experience and skills in plate making, lithographic printing, and prepress techniques.

- Showcase your proficiency in using industry-standard software and equipment.

- Quantify your accomplishments with specific metrics, such as the number of plates produced or the percentage of plates that met quality standards.

- Emphasize your attention to detail and commitment to producing high-quality work.

Essential Experience Highlights for a Strong Lithographic Plate Maker Resume

- Produce high-quality lithographic printing plates according to job specifications.

- Operate and maintain platemaking equipment, including CtP (computer-to-plate) systems.

- Calibrate and maintain densitometers to ensure accurate color reproduction.

- Inspect plates for defects and make necessary adjustments to ensure optimal printing results.

- Collaborate with prepress and press operators to troubleshoot and resolve printing issues.

- Stay up-to-date with the latest lithographic printing technologies and techniques.

Frequently Asked Questions (FAQ’s) For Lithographic Plate Maker

What is the role of a Lithographic Plate Maker?

A Lithographic Plate Maker is responsible for creating the printing plates used in lithographic printing. They ensure that the plates meet the required specifications and produce high-quality prints.

What are the key skills required for a Lithographic Plate Maker?

Key skills for a Lithographic Plate Maker include plate making, lithographic printing, prepress, CTP, color management, and densitometry.

What is the educational background required for a Lithographic Plate Maker?

An Associate degree in Graphic Communications or a related field is typically required for a Lithographic Plate Maker.

What are the career prospects for a Lithographic Plate Maker?

Lithographic Plate Makers can advance to supervisory or management roles or specialize in specific areas such as color management or prepress.

What are the challenges faced by a Lithographic Plate Maker?

Lithographic Plate Makers may face challenges such as ensuring accurate color reproduction, meeting tight deadlines, and staying up-to-date with the latest printing technologies.

What is the salary range for a Lithographic Plate Maker?

The salary range for a Lithographic Plate Maker can vary depending on experience, location, and company size.