Are you a seasoned Lithographic Platemaker seeking a new career path? Discover our professionally built Lithographic Platemaker Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

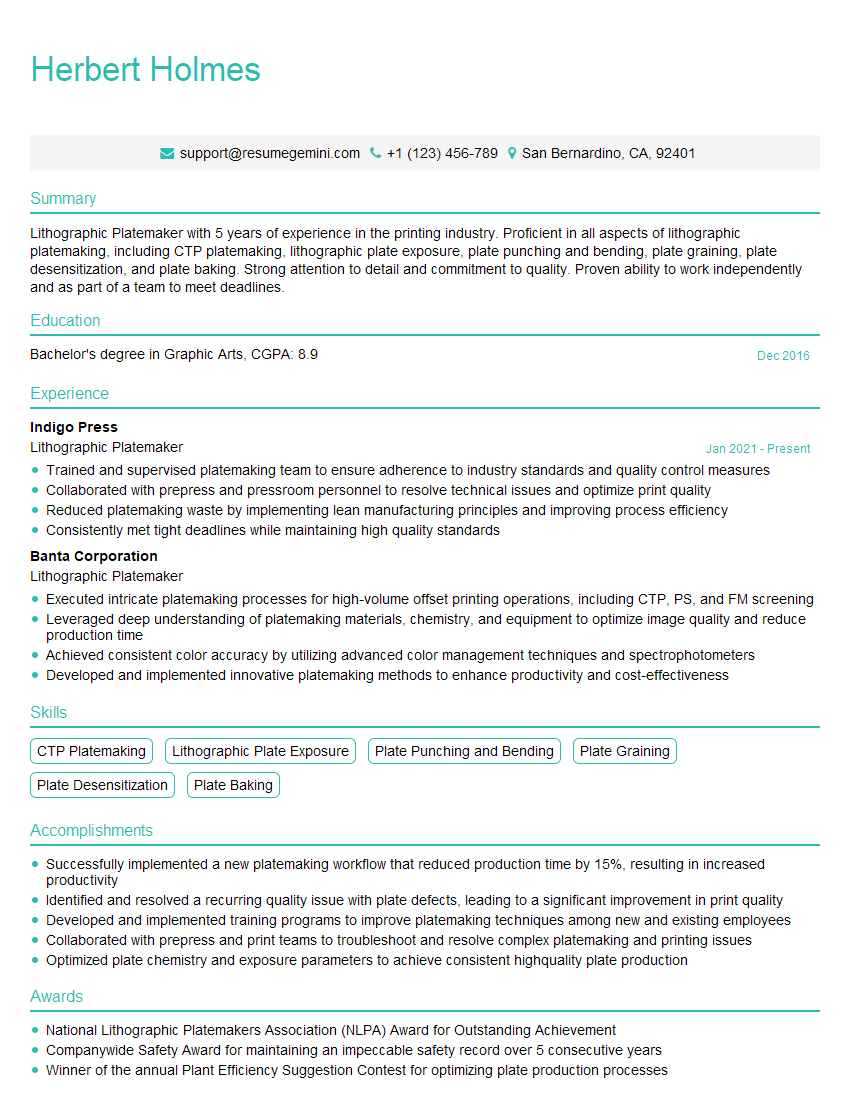

Herbert Holmes

Lithographic Platemaker

Summary

Lithographic Platemaker with 5 years of experience in the printing industry. Proficient in all aspects of lithographic platemaking, including CTP platemaking, lithographic plate exposure, plate punching and bending, plate graining, plate desensitization, and plate baking. Strong attention to detail and commitment to quality. Proven ability to work independently and as part of a team to meet deadlines.

Education

Bachelor’s degree in Graphic Arts

December 2016

Skills

- CTP Platemaking

- Lithographic Plate Exposure

- Plate Punching and Bending

- Plate Graining

- Plate Desensitization

- Plate Baking

Work Experience

Lithographic Platemaker

- Trained and supervised platemaking team to ensure adherence to industry standards and quality control measures

- Collaborated with prepress and pressroom personnel to resolve technical issues and optimize print quality

- Reduced platemaking waste by implementing lean manufacturing principles and improving process efficiency

- Consistently met tight deadlines while maintaining high quality standards

Lithographic Platemaker

- Executed intricate platemaking processes for high-volume offset printing operations, including CTP, PS, and FM screening

- Leveraged deep understanding of platemaking materials, chemistry, and equipment to optimize image quality and reduce production time

- Achieved consistent color accuracy by utilizing advanced color management techniques and spectrophotometers

- Developed and implemented innovative platemaking methods to enhance productivity and cost-effectiveness

Accomplishments

- Successfully implemented a new platemaking workflow that reduced production time by 15%, resulting in increased productivity

- Identified and resolved a recurring quality issue with plate defects, leading to a significant improvement in print quality

- Developed and implemented training programs to improve platemaking techniques among new and existing employees

- Collaborated with prepress and print teams to troubleshoot and resolve complex platemaking and printing issues

- Optimized plate chemistry and exposure parameters to achieve consistent highquality plate production

Awards

- National Lithographic Platemakers Association (NLPA) Award for Outstanding Achievement

- Companywide Safety Award for maintaining an impeccable safety record over 5 consecutive years

- Winner of the annual Plant Efficiency Suggestion Contest for optimizing plate production processes

Certificates

- Certified Lithographic Platemaker (CLP)

- Certified Prepress Technician (CPT)

- ISO 9001 Certification

- Lean Manufacturing Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Lithographic Platemaker

- Highlight your skills and experience in lithographic platemaking.

- Quantify your accomplishments whenever possible.

- Proofread your resume carefully before submitting it.

- Tailor your resume to each job you apply for.

Essential Experience Highlights for a Strong Lithographic Platemaker Resume

- Operate and maintain lithographic platemaking equipment

- Prepare and process lithographic plates for printing

- Inspect plates for defects and make corrections as necessary

- Maintain inventory of plates and platemaking supplies

- Follow safety and environmental procedures

- Troubleshoot and resolve problems with platemaking equipment and processes

Frequently Asked Questions (FAQ’s) For Lithographic Platemaker

What is the role of a Lithographic Platemaker?

A Lithographic Platemaker is responsible for creating the plates that are used in lithographic printing. This involves preparing the plates, exposing them to light, and developing them. Lithographic Platemakers must have a strong understanding of the printing process and be able to operate a variety of equipment.

What are the qualifications for becoming a Lithographic Platemaker?

Most Lithographic Platemakers have a high school diploma or equivalent. However, some employers may prefer candidates with a degree in graphic arts or a related field. In addition, Lithographic Platemakers must have a strong understanding of the printing process and be able to operate a variety of equipment.

What are the job prospects for Lithographic Platemakers?

The job outlook for Lithographic Platemakers is expected to be good over the next few years. As the demand for printed materials continues to grow, so too will the demand for Lithographic Platemakers.

What are the salary expectations for Lithographic Platemakers?

The salary for Lithographic Platemakers can vary depending on their experience and location. However, the median salary for Lithographic Platemakers is around $45,000 per year.

What are the working conditions for Lithographic Platemakers?

Lithographic Platemakers typically work in a printing plant or a related environment. The work can be physically demanding, as it requires standing for long periods of time and lifting heavy objects. However, the work is also typically performed in a climate-controlled environment.