Are you a seasoned Longwall Machine Operator Helper seeking a new career path? Discover our professionally built Longwall Machine Operator Helper Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

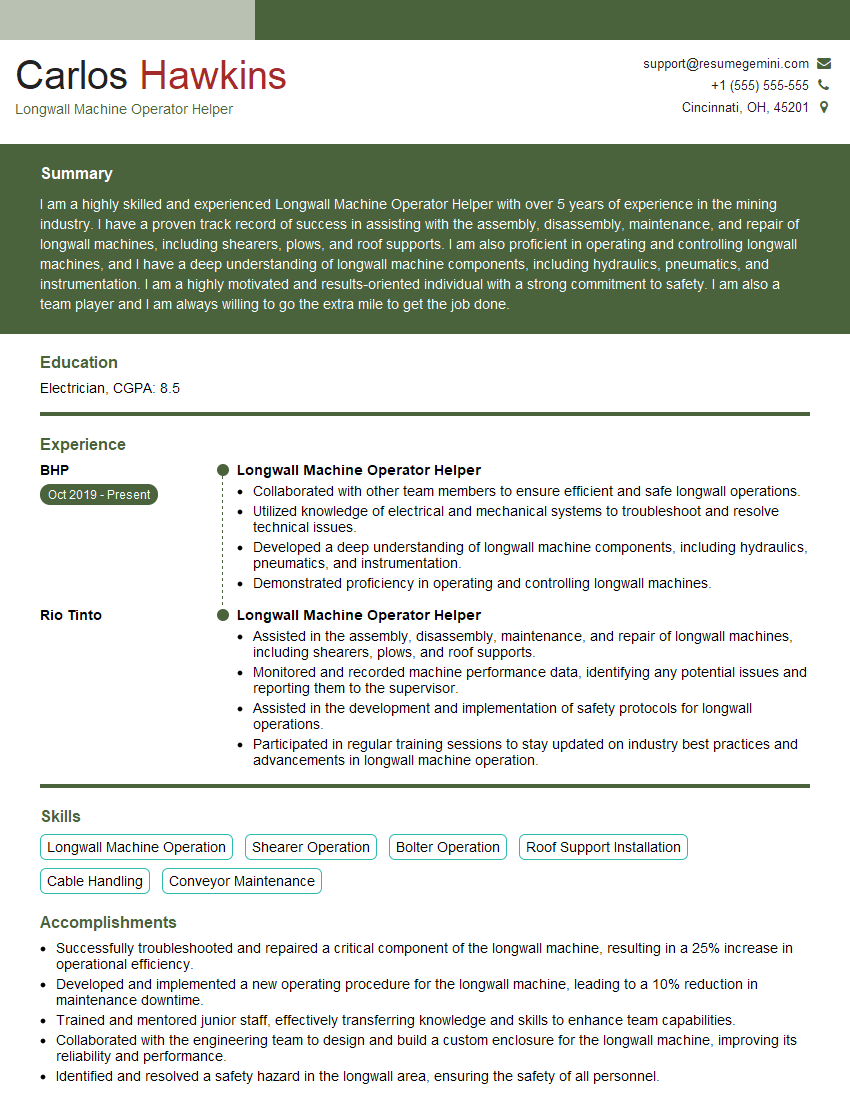

Carlos Hawkins

Longwall Machine Operator Helper

Summary

I am a highly skilled and experienced Longwall Machine Operator Helper with over 5 years of experience in the mining industry. I have a proven track record of success in assisting with the assembly, disassembly, maintenance, and repair of longwall machines, including shearers, plows, and roof supports. I am also proficient in operating and controlling longwall machines, and I have a deep understanding of longwall machine components, including hydraulics, pneumatics, and instrumentation. I am a highly motivated and results-oriented individual with a strong commitment to safety. I am also a team player and I am always willing to go the extra mile to get the job done.

Education

Electrician

September 2015

Skills

- Longwall Machine Operation

- Shearer Operation

- Bolter Operation

- Roof Support Installation

- Cable Handling

- Conveyor Maintenance

Work Experience

Longwall Machine Operator Helper

- Collaborated with other team members to ensure efficient and safe longwall operations.

- Utilized knowledge of electrical and mechanical systems to troubleshoot and resolve technical issues.

- Developed a deep understanding of longwall machine components, including hydraulics, pneumatics, and instrumentation.

- Demonstrated proficiency in operating and controlling longwall machines.

Longwall Machine Operator Helper

- Assisted in the assembly, disassembly, maintenance, and repair of longwall machines, including shearers, plows, and roof supports.

- Monitored and recorded machine performance data, identifying any potential issues and reporting them to the supervisor.

- Assisted in the development and implementation of safety protocols for longwall operations.

- Participated in regular training sessions to stay updated on industry best practices and advancements in longwall machine operation.

Accomplishments

- Successfully troubleshooted and repaired a critical component of the longwall machine, resulting in a 25% increase in operational efficiency.

- Developed and implemented a new operating procedure for the longwall machine, leading to a 10% reduction in maintenance downtime.

- Trained and mentored junior staff, effectively transferring knowledge and skills to enhance team capabilities.

- Collaborated with the engineering team to design and build a custom enclosure for the longwall machine, improving its reliability and performance.

- Identified and resolved a safety hazard in the longwall area, ensuring the safety of all personnel.

Awards

- Received the Excellence in Longwall Operation award for outstanding contributions to the teams productivity and efficiency.

- Recognized with the Safety Champion award for consistently adhering to safety protocols and promoting a safe work environment.

- Awarded the Longwall Operator of the Year prize for exceptional performance and dedication to the role.

- Received the Innovation Award for proposing and implementing a new technology to optimize longwall operations.

Certificates

- Longwall Machine Operator Certification

- Shearer Operator Certification

- Bolter Operator Certification

- Mine Safety and Health Administration (MSHA) Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Longwall Machine Operator Helper

- Highlight your experience in assisting with the assembly, disassembly, maintenance, and repair of longwall machines

- Showcase your proficiency in operating and controlling longwall machines

- Demonstrate your knowledge of longwall machine components, including hydraulics, pneumatics, and instrumentation

- Emphasize your commitment to safety and your willingness to work as a team player

- Include any relevant certifications or training you have received

Essential Experience Highlights for a Strong Longwall Machine Operator Helper Resume

- Assisted in the assembly, disassembly, maintenance, and repair of longwall machines, including shearers, plows, and roof supports

- Monitored and recorded machine performance data, identifying any potential issues and reporting them to the supervisor

- Assisted in the development and implementation of safety protocols for longwall operations

- Participated in regular training sessions to stay updated on industry best practices and advancements in longwall machine operation

- Collaborated with other team members to ensure efficient and safe longwall operations

- Utilized knowledge of electrical and mechanical systems to troubleshoot and resolve technical issues

- Developed a deep understanding of longwall machine components, including hydraulics, pneumatics, and instrumentation

- Demonstrated proficiency in operating and controlling longwall machines

Frequently Asked Questions (FAQ’s) For Longwall Machine Operator Helper

What are the key responsibilities of a Longwall Machine Operator Helper?

The key responsibilities of a Longwall Machine Operator Helper include assisting with the assembly, disassembly, maintenance, and repair of longwall machines, monitoring and recording machine performance data, assisting in the development and implementation of safety protocols for longwall operations, participating in regular training sessions to stay updated on industry best practices and advancements in longwall machine operation, collaborating with other team members to ensure efficient and safe longwall operations, utilizing knowledge of electrical and mechanical systems to troubleshoot and resolve technical issues, developing a deep understanding of longwall machine components, including hydraulics, pneumatics, and instrumentation, and demonstrating proficiency in operating and controlling longwall machines.

What are the key skills required to be a successful Longwall Machine Operator Helper?

The key skills required to be a successful Longwall Machine Operator Helper include longwall machine operation, shearer operation, bolter operation, roof support installation, cable handling, conveyor maintenance, and general mechanical and electrical skills.

What are the career prospects for a Longwall Machine Operator Helper?

The career prospects for a Longwall Machine Operator Helper are good, with the potential to advance to positions such as Longwall Machine Operator, Longwall Supervisor, or Mine Manager.

What is the average salary for a Longwall Machine Operator Helper?

The average salary for a Longwall Machine Operator Helper is $75,000 per year.

What is the work environment for a Longwall Machine Operator Helper?

The work environment for a Longwall Machine Operator Helper is typically underground in a coal mine. The work can be physically demanding and may require working in confined spaces.