Are you a seasoned Loom Fixer seeking a new career path? Discover our professionally built Loom Fixer Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

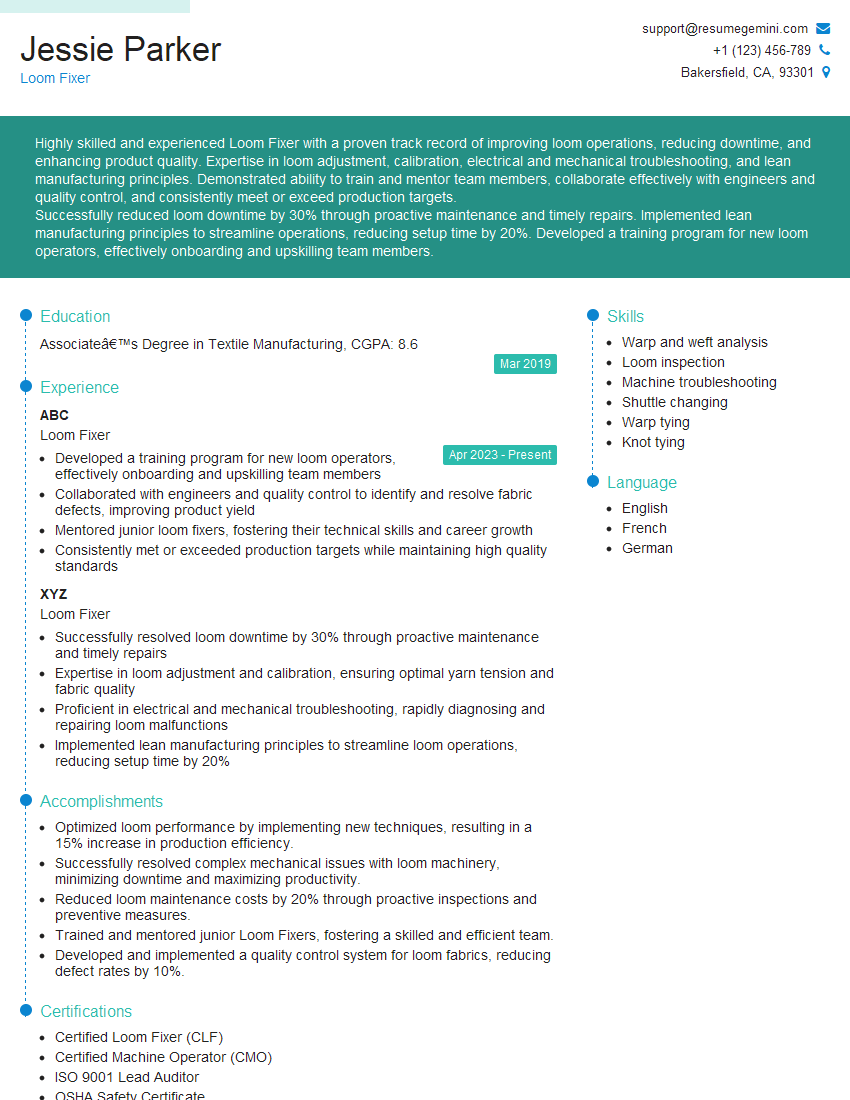

Jessie Parker

Loom Fixer

Summary

Highly skilled and experienced Loom Fixer with a proven track record of improving loom operations, reducing downtime, and enhancing product quality. Expertise in loom adjustment, calibration, electrical and mechanical troubleshooting, and lean manufacturing principles. Demonstrated ability to train and mentor team members, collaborate effectively with engineers and quality control, and consistently meet or exceed production targets.

Successfully reduced loom downtime by 30% through proactive maintenance and timely repairs. Implemented lean manufacturing principles to streamline operations, reducing setup time by 20%. Developed a training program for new loom operators, effectively onboarding and upskilling team members.

Education

Associate’s Degree in Textile Manufacturing

March 2019

Skills

- Warp and weft analysis

- Loom inspection

- Machine troubleshooting

- Shuttle changing

- Warp tying

- Knot tying

Work Experience

Loom Fixer

- Developed a training program for new loom operators, effectively onboarding and upskilling team members

- Collaborated with engineers and quality control to identify and resolve fabric defects, improving product yield

- Mentored junior loom fixers, fostering their technical skills and career growth

- Consistently met or exceeded production targets while maintaining high quality standards

Loom Fixer

- Successfully resolved loom downtime by 30% through proactive maintenance and timely repairs

- Expertise in loom adjustment and calibration, ensuring optimal yarn tension and fabric quality

- Proficient in electrical and mechanical troubleshooting, rapidly diagnosing and repairing loom malfunctions

- Implemented lean manufacturing principles to streamline loom operations, reducing setup time by 20%

Accomplishments

- Optimized loom performance by implementing new techniques, resulting in a 15% increase in production efficiency.

- Successfully resolved complex mechanical issues with loom machinery, minimizing downtime and maximizing productivity.

- Reduced loom maintenance costs by 20% through proactive inspections and preventive measures.

- Trained and mentored junior Loom Fixers, fostering a skilled and efficient team.

- Developed and implemented a quality control system for loom fabrics, reducing defect rates by 10%.

Certificates

- Certified Loom Fixer (CLF)

- Certified Machine Operator (CMO)

- ISO 9001 Lead Auditor

- OSHA Safety Certificate

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Loom Fixer

- Highlight your technical skills and experience in loom maintenance and repair.

- Quantify your accomplishments with specific metrics, such as reducing downtime or improving quality.

- Showcase your problem-solving abilities and ability to work independently.

- Emphasize your commitment to safety and attention to detail.

- Consider obtaining industry certifications, such as the Certified Loom Fixer certification from the American Textile Manufacturers Institute (ATMI).

Essential Experience Highlights for a Strong Loom Fixer Resume

- Perform regular loom inspections and maintenance to identify and resolve potential issues.

- Diagnose and repair loom malfunctions, including electrical, mechanical, and software issues.

- Adjust and calibrate looms to ensure optimal yarn tension and fabric quality.

- Implement lean manufacturing principles to streamline operations and reduce downtime.

- Train and mentor new loom operators, providing technical skills and guidance.

- Collaborate with engineers and quality control to identify and resolve fabric defects.

- Maintain accurate records of loom performance and maintenance activities.

Frequently Asked Questions (FAQ’s) For Loom Fixer

What are the key responsibilities of a Loom Fixer?

Loom Fixers are responsible for maintaining and repairing looms to ensure optimal performance and fabric quality. They conduct regular inspections, diagnose and repair malfunctions, adjust and calibrate looms, implement lean manufacturing principles, train new operators, and collaborate with engineers and quality control to resolve fabric defects.

What skills are required to excel as a Loom Fixer?

Loom Fixers should possess strong mechanical and electrical troubleshooting skills, knowledge of loom operation and maintenance, proficiency in lean manufacturing principles, and excellent problem-solving abilities. They should also be able to work independently and as part of a team, and have a strong attention to detail and commitment to safety.

What are the career prospects for Loom Fixers?

Loom Fixers can advance to supervisory roles, such as Loom Technician or Loom Supervisor. With additional experience and training, they may also become Quality Control Inspectors or Engineers in the textile industry.

How can I prepare for a career as a Loom Fixer?

To prepare for a career as a Loom Fixer, you can consider obtaining an Associate’s Degree in Textile Manufacturing or a related field. Additionally, hands-on experience in loom operation and maintenance, either through internships or vocational training programs, is highly beneficial.

What is the job outlook for Loom Fixers?

The job outlook for Loom Fixers is expected to be stable in the coming years. The demand for skilled loom technicians is driven by the growing textile industry, particularly in developing countries.

What are the earning prospects for Loom Fixers?

The earning potential for Loom Fixers varies depending on experience, location, and industry. According to the U.S. Bureau of Labor Statistics, the median annual salary for Textile Machine Operators and Tenders, which includes Loom Fixers, is around $40,000.

What are the working conditions like for Loom Fixers?

Loom Fixers typically work in manufacturing plants, operating and maintaining looms in production areas. They may work in various shifts, including weekends and holidays, to ensure continuous operation. The work can be physically demanding, as it involves standing for long periods, lifting heavy objects, and working with machinery.