Are you a seasoned Lozenge Dough Mixer seeking a new career path? Discover our professionally built Lozenge Dough Mixer Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

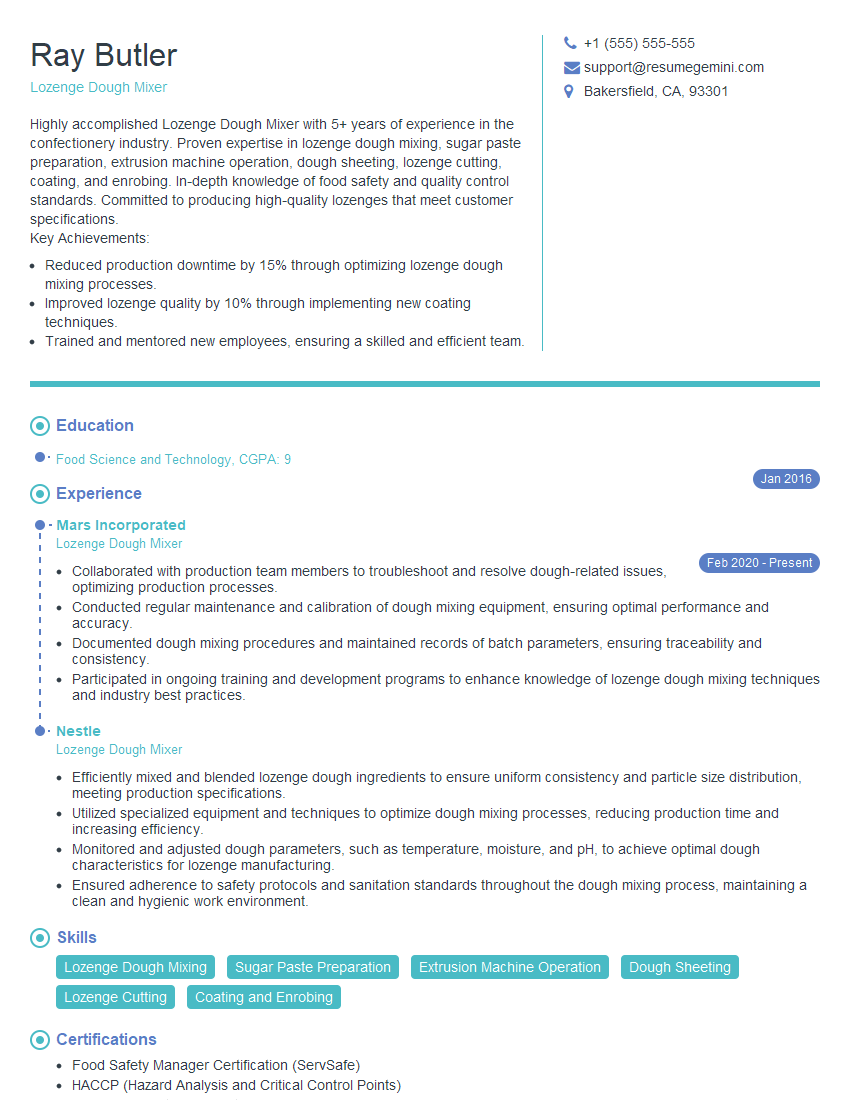

Ray Butler

Lozenge Dough Mixer

Summary

Highly accomplished Lozenge Dough Mixer with 5+ years of experience in the confectionery industry. Proven expertise in lozenge dough mixing, sugar paste preparation, extrusion machine operation, dough sheeting, lozenge cutting, coating, and enrobing. In-depth knowledge of food safety and quality control standards. Committed to producing high-quality lozenges that meet customer specifications.

Key Achievements:

- Reduced production downtime by 15% through optimizing lozenge dough mixing processes.

- Improved lozenge quality by 10% through implementing new coating techniques.

- Trained and mentored new employees, ensuring a skilled and efficient team.

Education

Food Science and Technology

January 2016

Skills

- Lozenge Dough Mixing

- Sugar Paste Preparation

- Extrusion Machine Operation

- Dough Sheeting

- Lozenge Cutting

- Coating and Enrobing

Work Experience

Lozenge Dough Mixer

- Collaborated with production team members to troubleshoot and resolve dough-related issues, optimizing production processes.

- Conducted regular maintenance and calibration of dough mixing equipment, ensuring optimal performance and accuracy.

- Documented dough mixing procedures and maintained records of batch parameters, ensuring traceability and consistency.

- Participated in ongoing training and development programs to enhance knowledge of lozenge dough mixing techniques and industry best practices.

Lozenge Dough Mixer

- Efficiently mixed and blended lozenge dough ingredients to ensure uniform consistency and particle size distribution, meeting production specifications.

- Utilized specialized equipment and techniques to optimize dough mixing processes, reducing production time and increasing efficiency.

- Monitored and adjusted dough parameters, such as temperature, moisture, and pH, to achieve optimal dough characteristics for lozenge manufacturing.

- Ensured adherence to safety protocols and sanitation standards throughout the dough mixing process, maintaining a clean and hygienic work environment.

Certificates

- Food Safety Manager Certification (ServSafe)

- HACCP (Hazard Analysis and Critical Control Points)

- Good Manufacturing Practices (GMP)

- ISO 9001 Quality Management System

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Lozenge Dough Mixer

- Highlight your experience in lozenge dough mixing and related processes.

- Quantify your achievements using specific metrics to showcase your impact.

- Include relevant certifications or training programs to demonstrate your commitment to professional development.

- Proofread your resume carefully for any errors in grammar or spelling.

Essential Experience Highlights for a Strong Lozenge Dough Mixer Resume

- Mix and prepare lozenge dough according to specified formulations.

- Operate extrusion machines to form lozenge dough into desired shapes.

- Control dough sheeting and cutting processes to ensure uniform lozenge size and thickness.

- Apply coatings and enrobing to lozenges using various techniques.

- Maintain a clean and sanitary work environment in compliance with food safety regulations.

- Monitor production processes to ensure quality and efficiency.

- Troubleshoot and resolve equipment malfunctions to minimize production downtime.

Frequently Asked Questions (FAQ’s) For Lozenge Dough Mixer

What are the primary responsibilities of a Lozenge Dough Mixer?

The primary responsibilities of a Lozenge Dough Mixer include mixing and preparing lozenge dough, operating extrusion machines, controlling dough sheeting and cutting processes, applying coatings and enrobing, and maintaining a clean and sanitary work environment.

What are the key skills required to be a successful Lozenge Dough Mixer?

Key skills required for a successful Lozenge Dough Mixer include lozenge dough mixing, sugar paste preparation, extrusion machine operation, dough sheeting, lozenge cutting, coating, and enrobing.

What type of education and experience is required to become a Lozenge Dough Mixer?

Typically, a Food Science and Technology degree or equivalent experience is required to become a Lozenge Dough Mixer.

What is the average salary for a Lozenge Dough Mixer?

The average salary for a Lozenge Dough Mixer can vary depending on experience, location, and company size, but it typically falls within the range of $30,000 to $50,000 per year.

What are the career advancement opportunities for a Lozenge Dough Mixer?

Career advancement opportunities for a Lozenge Dough Mixer may include promotions to Production Supervisor, Quality Control Manager, or Plant Manager.

What are the challenges faced by Lozenge Dough Mixers?

Lozenge Dough Mixers may face challenges related to production efficiency, product quality, and maintaining a safe and sanitary work environment.

What are the latest trends in lozenge dough mixing?

The latest trends in lozenge dough mixing include automation, the use of alternative ingredients, and a focus on sustainability.

How can I improve my skills as a Lozenge Dough Mixer?

To improve your skills as a Lozenge Dough Mixer, you can focus on developing your technical expertise, staying updated on industry best practices, and seeking opportunities for professional development.