Are you a seasoned Lubricating Machine Tender seeking a new career path? Discover our professionally built Lubricating Machine Tender Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

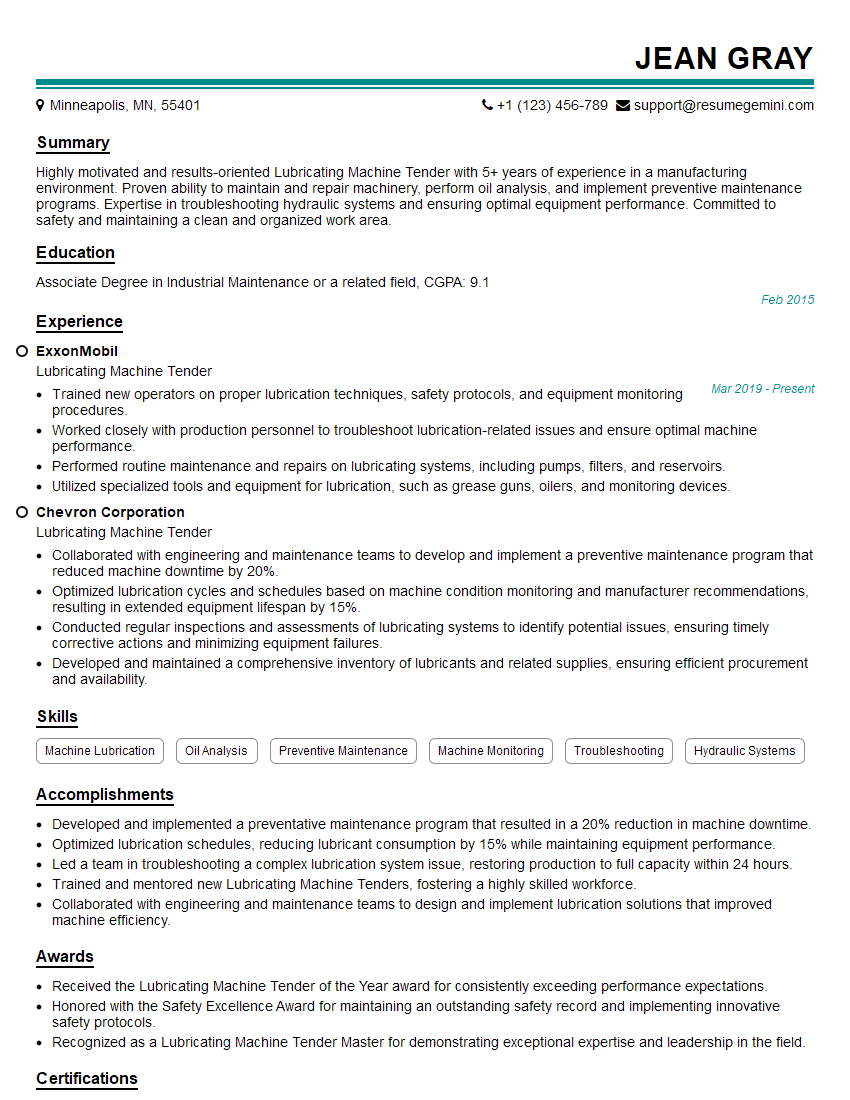

Jean Gray

Lubricating Machine Tender

Summary

Highly motivated and results-oriented Lubricating Machine Tender with 5+ years of experience in a manufacturing environment. Proven ability to maintain and repair machinery, perform oil analysis, and implement preventive maintenance programs. Expertise in troubleshooting hydraulic systems and ensuring optimal equipment performance. Committed to safety and maintaining a clean and organized work area.

Education

Associate Degree in Industrial Maintenance or a related field

February 2015

Skills

- Machine Lubrication

- Oil Analysis

- Preventive Maintenance

- Machine Monitoring

- Troubleshooting

- Hydraulic Systems

Work Experience

Lubricating Machine Tender

- Trained new operators on proper lubrication techniques, safety protocols, and equipment monitoring procedures.

- Worked closely with production personnel to troubleshoot lubrication-related issues and ensure optimal machine performance.

- Performed routine maintenance and repairs on lubricating systems, including pumps, filters, and reservoirs.

- Utilized specialized tools and equipment for lubrication, such as grease guns, oilers, and monitoring devices.

Lubricating Machine Tender

- Collaborated with engineering and maintenance teams to develop and implement a preventive maintenance program that reduced machine downtime by 20%.

- Optimized lubrication cycles and schedules based on machine condition monitoring and manufacturer recommendations, resulting in extended equipment lifespan by 15%.

- Conducted regular inspections and assessments of lubricating systems to identify potential issues, ensuring timely corrective actions and minimizing equipment failures.

- Developed and maintained a comprehensive inventory of lubricants and related supplies, ensuring efficient procurement and availability.

Accomplishments

- Developed and implemented a preventative maintenance program that resulted in a 20% reduction in machine downtime.

- Optimized lubrication schedules, reducing lubricant consumption by 15% while maintaining equipment performance.

- Led a team in troubleshooting a complex lubrication system issue, restoring production to full capacity within 24 hours.

- Trained and mentored new Lubricating Machine Tenders, fostering a highly skilled workforce.

- Collaborated with engineering and maintenance teams to design and implement lubrication solutions that improved machine efficiency.

Awards

- Received the Lubricating Machine Tender of the Year award for consistently exceeding performance expectations.

- Honored with the Safety Excellence Award for maintaining an outstanding safety record and implementing innovative safety protocols.

- Recognized as a Lubricating Machine Tender Master for demonstrating exceptional expertise and leadership in the field.

Certificates

- Certified Lubrication Technician (CLT)

- Certified Maintenance & Reliability Technician (CMRT)

- Certified Lubrication Engineer (CLE)

- Certified Reliability Engineer (CRE)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Lubricating Machine Tender

- Highlight your experience in maintaining and repairing various types of machinery.

- Showcase your knowledge of lubrication principles and oil analysis techniques.

- Emphasize your ability to troubleshoot and resolve mechanical issues efficiently.

- Demonstrate your commitment to safety and following established procedures.

- Include quantifiable results whenever possible to showcase the impact of your work.

Essential Experience Highlights for a Strong Lubricating Machine Tender Resume

- Lubricate and maintain machinery according to established schedules and procedures

- Monitor machine performance and conduct regular inspections to identify potential issues

- Perform oil analysis and interpret results to determine oil condition and recommend maintenance actions

- Troubleshoot and repair machinery, including hydraulic systems, bearings, and pumps

- Implement preventive maintenance programs to minimize downtime and extend equipment life

- Maintain a clean and organized work area, ensuring proper lubrication and safety standards

- Keep accurate records of maintenance activities and report any issues to supervisors

Frequently Asked Questions (FAQ’s) For Lubricating Machine Tender

What are the key skills required for a Lubricating Machine Tender?

Key skills include machine lubrication, oil analysis, preventive maintenance, machine monitoring, troubleshooting, and hydraulic systems.

What is the typical work environment for a Lubricating Machine Tender?

Lubricating Machine Tenders typically work in industrial settings, such as manufacturing plants, power plants, and oil and gas facilities.

What are the career prospects for a Lubricating Machine Tender?

With experience and additional training, Lubricating Machine Tenders can advance to positions such as Maintenance Technician, Maintenance Supervisor, or Plant Manager.

What is the average salary for a Lubricating Machine Tender?

According to Indeed, the average salary for a Lubricating Machine Tender in the United States is around $50,000 per year.

What are the common challenges faced by Lubricating Machine Tenders?

Common challenges include working in noisy and potentially hazardous environments, dealing with heavy machinery, and the need to stay up-to-date with industry best practices.

What are the safety precautions that Lubricating Machine Tenders should follow?

Important safety precautions include wearing appropriate personal protective equipment, following lockout/tagout procedures, and being aware of potential hazards such as moving machinery and electrical equipment.

What is the role of oil analysis in the work of a Lubricating Machine Tender?

Oil analysis helps Lubricating Machine Tenders monitor the condition of machinery by analyzing the properties of oil samples, allowing them to identify potential issues and schedule maintenance accordingly.