Are you a seasoned Lubricating Specialist seeking a new career path? Discover our professionally built Lubricating Specialist Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

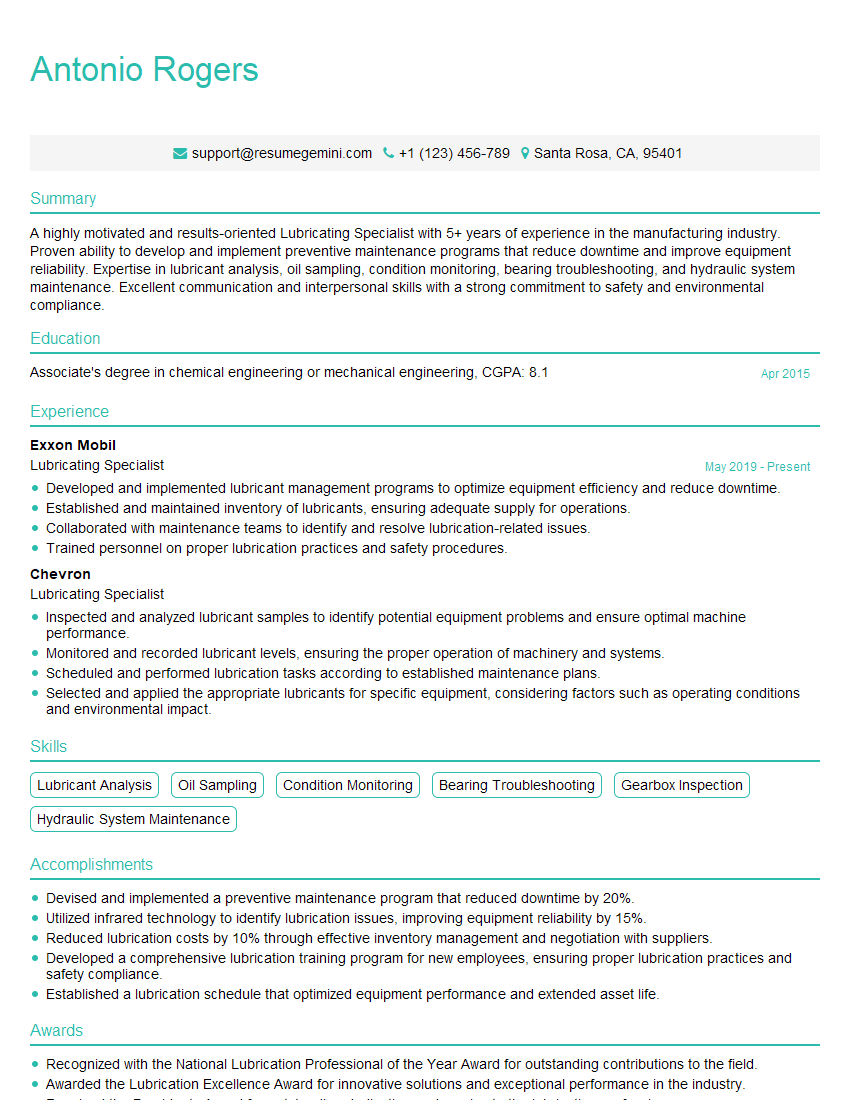

Antonio Rogers

Lubricating Specialist

Summary

A highly motivated and results-oriented Lubricating Specialist with 5+ years of experience in the manufacturing industry. Proven ability to develop and implement preventive maintenance programs that reduce downtime and improve equipment reliability. Expertise in lubricant analysis, oil sampling, condition monitoring, bearing troubleshooting, and hydraulic system maintenance. Excellent communication and interpersonal skills with a strong commitment to safety and environmental compliance.

Education

Associate’s degree in chemical engineering or mechanical engineering

April 2015

Skills

- Lubricant Analysis

- Oil Sampling

- Condition Monitoring

- Bearing Troubleshooting

- Gearbox Inspection

- Hydraulic System Maintenance

Work Experience

Lubricating Specialist

- Developed and implemented lubricant management programs to optimize equipment efficiency and reduce downtime.

- Established and maintained inventory of lubricants, ensuring adequate supply for operations.

- Collaborated with maintenance teams to identify and resolve lubrication-related issues.

- Trained personnel on proper lubrication practices and safety procedures.

Lubricating Specialist

- Inspected and analyzed lubricant samples to identify potential equipment problems and ensure optimal machine performance.

- Monitored and recorded lubricant levels, ensuring the proper operation of machinery and systems.

- Scheduled and performed lubrication tasks according to established maintenance plans.

- Selected and applied the appropriate lubricants for specific equipment, considering factors such as operating conditions and environmental impact.

Accomplishments

- Devised and implemented a preventive maintenance program that reduced downtime by 20%.

- Utilized infrared technology to identify lubrication issues, improving equipment reliability by 15%.

- Reduced lubrication costs by 10% through effective inventory management and negotiation with suppliers.

- Developed a comprehensive lubrication training program for new employees, ensuring proper lubrication practices and safety compliance.

- Established a lubrication schedule that optimized equipment performance and extended asset life.

Awards

- Recognized with the National Lubrication Professional of the Year Award for outstanding contributions to the field.

- Awarded the Lubrication Excellence Award for innovative solutions and exceptional performance in the industry.

- Received the Presidents Award for outstanding dedication and service to the lubrication profession.

- Recognized with the Excellence in Lubrication Technology Award for advancements in equipment reliability and efficiency.

Certificates

- Certified Lubrication Technician (CLT)

- Machinery Lubrication Technician (MLT)

- Reliability Leadership Institute Certificate Level 1 (RL1)

- Reliability Leadership Institute Certificate Level 2 (RL2)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Lubricating Specialist

- Highlight your experience in developing and implementing preventive maintenance programs that have reduced downtime and improved equipment reliability.

- Showcase your expertise in lubricant analysis, oil sampling, and condition monitoring techniques.

- Emphasize your ability to troubleshoot bearing and gearbox problems, and to perform repairs and replacements as needed.

- Demonstrate your knowledge of hydraulic system maintenance, including fluid changes, filter replacements, and system inspections.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate the impact of your work.

Essential Experience Highlights for a Strong Lubricating Specialist Resume

- Develop and implement preventive maintenance programs to minimize downtime and optimize equipment performance.

- Conduct lubricant analysis, oil sampling, and condition monitoring to identify potential lubrication issues and recommend corrective actions.

- Troubleshoot bearing and gearbox problems, and perform repairs and replacements as needed.

- Conduct hydraulic system maintenance, including fluid changes, filter replacements, and system inspections.

- Establish and maintain lubrication schedules to ensure optimal equipment performance and extend asset life.

- Provide technical support to maintenance personnel and operators, and conduct training on lubrication best practices.

- Monitor and control lubrication inventory, and negotiate with suppliers to reduce costs.

Frequently Asked Questions (FAQ’s) For Lubricating Specialist

What is the primary role of a Lubricating Specialist?

The primary role of a Lubricating Specialist is to ensure the proper lubrication of industrial machinery and equipment. This involves selecting the appropriate lubricants, developing lubrication schedules, conducting lubricant analysis, and troubleshooting lubrication-related problems.

What are the key skills and qualifications required for a Lubricating Specialist?

Key skills and qualifications for a Lubricating Specialist include a strong understanding of lubrication principles, experience in lubricant analysis and condition monitoring, and proficiency in troubleshooting lubrication-related problems. Additionally, Lubricating Specialists should have excellent communication and interpersonal skills.

What industries employ Lubricating Specialists?

Lubricating Specialists are employed in a variety of industries, including manufacturing, mining, transportation, and power generation.

What is the job outlook for Lubricating Specialists?

The job outlook for Lubricating Specialists is expected to be good over the next few years. As businesses continue to focus on improving efficiency and reducing downtime, the demand for qualified Lubricating Specialists is likely to increase.

What is the average salary for a Lubricating Specialist?

The average salary for a Lubricating Specialist varies depending on experience, location, and industry. However, according to the U.S. Bureau of Labor Statistics, the median annual salary for Lubricating Specialists was $60,920 in May 2021.

What are the advancement opportunities for a Lubricating Specialist?

Advancement opportunities for a Lubricating Specialist include promotion to supervisor or manager, or specialization in a particular area of lubrication, such as lubricant analysis or condition monitoring.