Are you a seasoned Lumber Kiln Operator seeking a new career path? Discover our professionally built Lumber Kiln Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

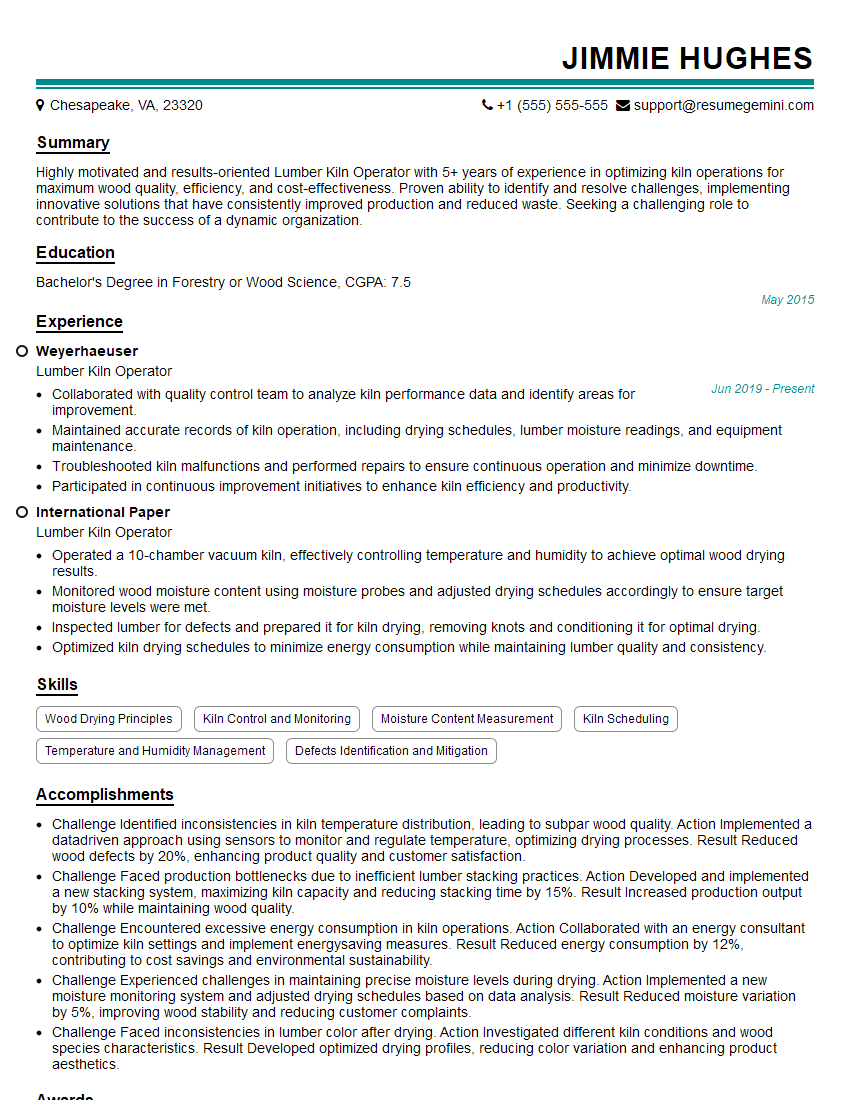

Jimmie Hughes

Lumber Kiln Operator

Summary

Highly motivated and results-oriented Lumber Kiln Operator with 5+ years of experience in optimizing kiln operations for maximum wood quality, efficiency, and cost-effectiveness. Proven ability to identify and resolve challenges, implementing innovative solutions that have consistently improved production and reduced waste. Seeking a challenging role to contribute to the success of a dynamic organization.

Education

Bachelor’s Degree in Forestry or Wood Science

May 2015

Skills

- Wood Drying Principles

- Kiln Control and Monitoring

- Moisture Content Measurement

- Kiln Scheduling

- Temperature and Humidity Management

- Defects Identification and Mitigation

Work Experience

Lumber Kiln Operator

- Collaborated with quality control team to analyze kiln performance data and identify areas for improvement.

- Maintained accurate records of kiln operation, including drying schedules, lumber moisture readings, and equipment maintenance.

- Troubleshooted kiln malfunctions and performed repairs to ensure continuous operation and minimize downtime.

- Participated in continuous improvement initiatives to enhance kiln efficiency and productivity.

Lumber Kiln Operator

- Operated a 10-chamber vacuum kiln, effectively controlling temperature and humidity to achieve optimal wood drying results.

- Monitored wood moisture content using moisture probes and adjusted drying schedules accordingly to ensure target moisture levels were met.

- Inspected lumber for defects and prepared it for kiln drying, removing knots and conditioning it for optimal drying.

- Optimized kiln drying schedules to minimize energy consumption while maintaining lumber quality and consistency.

Accomplishments

- Challenge Identified inconsistencies in kiln temperature distribution, leading to subpar wood quality. Action Implemented a datadriven approach using sensors to monitor and regulate temperature, optimizing drying processes. Result Reduced wood defects by 20%, enhancing product quality and customer satisfaction.

- Challenge Faced production bottlenecks due to inefficient lumber stacking practices. Action Developed and implemented a new stacking system, maximizing kiln capacity and reducing stacking time by 15%. Result Increased production output by 10% while maintaining wood quality.

- Challenge Encountered excessive energy consumption in kiln operations. Action Collaborated with an energy consultant to optimize kiln settings and implement energysaving measures. Result Reduced energy consumption by 12%, contributing to cost savings and environmental sustainability.

- Challenge Experienced challenges in maintaining precise moisture levels during drying. Action Implemented a new moisture monitoring system and adjusted drying schedules based on data analysis. Result Reduced moisture variation by 5%, improving wood stability and reducing customer complaints.

- Challenge Faced inconsistencies in lumber color after drying. Action Investigated different kiln conditions and wood species characteristics. Result Developed optimized drying profiles, reducing color variation and enhancing product aesthetics.

Awards

- Received recognition for outstanding quality control in lumber kiln operations, resulting in reduced product defects and increased customer satisfaction.

- Awarded ‘Kiln Operator of the Year’ for exceptional performance in maintaining kiln temperature and humidity levels, ensuring optimal wood quality.

- Honored with a ‘Safety Excellence Award’ for consistently adhering to safety protocols and ensuring a hazardfree work environment in the lumber kiln.

Certificates

- Kiln Operator Certification (National Hardwood Lumber Association)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Lumber Kiln Operator

- Highlight your technical expertise in kiln operations, including knowledge of wood drying principles, kiln control systems, and moisture measurement techniques.

- Quantify your accomplishments with specific metrics and results, such as reductions in wood defects, increased production output, or energy savings.

- Demonstrate your problem-solving abilities and provide examples of how you have identified and resolved challenges in kiln operations.

- Showcase your commitment to continuous improvement and professional development by mentioning any certifications, training programs, or research projects you have undertaken.

Essential Experience Highlights for a Strong Lumber Kiln Operator Resume

- Monitor and control kiln operations, ensuring optimal temperature, humidity, and airflow conditions.

- Conduct regular quality checks of lumber to identify and mitigate drying defects.

- Calibrate and maintain kiln equipment, including sensors, controllers, and data logging systems.

- Schedule kiln loads and manage inventory to ensure efficient production flow.

- Collaborate with other departments to optimize raw material quality, production planning, and finished goods handling.

- Troubleshoot and resolve technical issues related to kiln operations.

- Stay abreast of industry best practices and technological advancements in lumber drying.

Frequently Asked Questions (FAQ’s) For Lumber Kiln Operator

What are the primary responsibilities of a Lumber Kiln Operator?

The primary responsibilities of a Lumber Kiln Operator include monitoring and controlling kiln operations to ensure optimal drying conditions, conducting quality checks of lumber to identify and mitigate defects, calibrating and maintaining kiln equipment, scheduling kiln loads and managing inventory, and collaborating with other departments to optimize production processes.

What qualifications are typically required to become a Lumber Kiln Operator?

Typically, a high school diploma or equivalent is required to become a Lumber Kiln Operator. Some employers may prefer candidates with a Bachelor’s degree in Forestry or Wood Science. Additionally, certification programs and hands-on experience in kiln operations are beneficial.

What are the career advancement opportunities for Lumber Kiln Operators?

With experience and additional training, Lumber Kiln Operators can advance to supervisory roles, such as Kiln Supervisor or Production Manager. They may also specialize in areas such as research and development or technical support.

What is the average salary range for Lumber Kiln Operators?

The average salary range for Lumber Kiln Operators varies depending on factors such as experience, location, and employer. According to Salary.com, the average salary range in the United States is between $40,000 and $60,000 per year.

What are the key skills and qualities that employers look for in Lumber Kiln Operators?

Employers look for Lumber Kiln Operators with a strong understanding of wood drying principles, kiln control systems, and moisture measurement techniques. They also value candidates with problem-solving abilities, attention to detail, and a commitment to safety.