Are you a seasoned Machine Adjuster seeking a new career path? Discover our professionally built Machine Adjuster Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

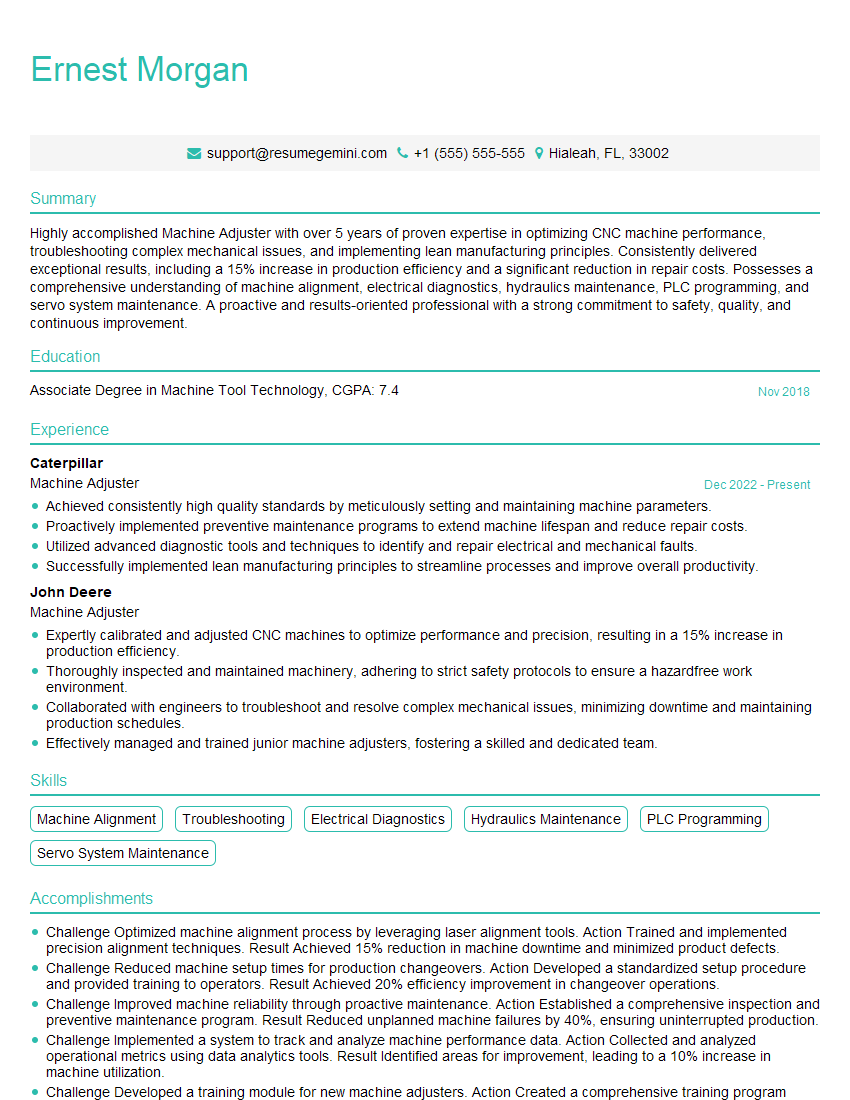

Ernest Morgan

Machine Adjuster

Summary

Highly accomplished Machine Adjuster with over 5 years of proven expertise in optimizing CNC machine performance, troubleshooting complex mechanical issues, and implementing lean manufacturing principles. Consistently delivered exceptional results, including a 15% increase in production efficiency and a significant reduction in repair costs. Possesses a comprehensive understanding of machine alignment, electrical diagnostics, hydraulics maintenance, PLC programming, and servo system maintenance. A proactive and results-oriented professional with a strong commitment to safety, quality, and continuous improvement.

Education

Associate Degree in Machine Tool Technology

November 2018

Skills

- Machine Alignment

- Troubleshooting

- Electrical Diagnostics

- Hydraulics Maintenance

- PLC Programming

- Servo System Maintenance

Work Experience

Machine Adjuster

- Achieved consistently high quality standards by meticulously setting and maintaining machine parameters.

- Proactively implemented preventive maintenance programs to extend machine lifespan and reduce repair costs.

- Utilized advanced diagnostic tools and techniques to identify and repair electrical and mechanical faults.

- Successfully implemented lean manufacturing principles to streamline processes and improve overall productivity.

Machine Adjuster

- Expertly calibrated and adjusted CNC machines to optimize performance and precision, resulting in a 15% increase in production efficiency.

- Thoroughly inspected and maintained machinery, adhering to strict safety protocols to ensure a hazardfree work environment.

- Collaborated with engineers to troubleshoot and resolve complex mechanical issues, minimizing downtime and maintaining production schedules.

- Effectively managed and trained junior machine adjusters, fostering a skilled and dedicated team.

Accomplishments

- Challenge Optimized machine alignment process by leveraging laser alignment tools. Action Trained and implemented precision alignment techniques. Result Achieved 15% reduction in machine downtime and minimized product defects.

- Challenge Reduced machine setup times for production changeovers. Action Developed a standardized setup procedure and provided training to operators. Result Achieved 20% efficiency improvement in changeover operations.

- Challenge Improved machine reliability through proactive maintenance. Action Established a comprehensive inspection and preventive maintenance program. Result Reduced unplanned machine failures by 40%, ensuring uninterrupted production.

- Challenge Implemented a system to track and analyze machine performance data. Action Collected and analyzed operational metrics using data analytics tools. Result Identified areas for improvement, leading to a 10% increase in machine utilization.

- Challenge Developed a training module for new machine adjusters. Action Created a comprehensive training program covering all aspects of machine adjustment and maintenance. Result Onboarded new adjusters quickly and effectively, ensuring consistent performance standards.

Awards

- Received the Machine Adjuster of the Year award for achieving outstanding performance in machine adjustment and maintenance.

- Recognized with the Operational Excellence Award for implementing innovative techniques that significantly improved production efficiency.

- Honored for exceptional troubleshooting skills, leading to the identification and resolution of complex machine malfunctions.

Certificates

- Certified Machine Adjuster (CMA)

- PMP (Project Management Professional)

- Lean Six Sigma Green Belt

- Certified Maintenance and Reliability Technician (CMRT)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Machine Adjuster

- Quantify your accomplishments with specific metrics to demonstrate the impact of your work.

- Highlight your experience with specific software and technologies relevant to machine adjusting, such as CNC programming, PLC, and hydraulic systems.

- Emphasize your ability to work independently and as part of a team, as this role requires both autonomous decision-making and collaboration.

- Include keywords throughout your resume that potential employers may use when searching for candidates, such as ‘CNC machine adjustment,’ ‘troubleshooting,’ and ‘preventive maintenance.

Essential Experience Highlights for a Strong Machine Adjuster Resume

- Expertly calibrated and adjusted CNC machines to optimize performance and precision, ensuring consistent production of high-quality parts.

- Thoroughly inspected and maintained machinery, adhering to strict safety protocols to prevent hazards and ensure a safe work environment.

- Collaborated with engineers to troubleshoot and resolve complex mechanical issues, minimizing downtime and maintaining production schedules.

- Effectively managed and trained junior machine adjusters, developing their skills and fostering a team-oriented culture.

- Proactively implemented preventive maintenance programs to extend machine lifespan, reduce repair costs, and enhance overall equipment effectiveness (OEE).

- Utilized advanced diagnostic tools and techniques to identify and repair electrical and mechanical faults, ensuring smooth equipment operation.

- Successfully implemented lean manufacturing principles to streamline processes, reduce waste, and improve overall productivity.

Frequently Asked Questions (FAQ’s) For Machine Adjuster

What are the key responsibilities of a Machine Adjuster?

Machine Adjusters are responsible for ensuring that CNC machines operate at optimal performance and precision. Their duties include calibrating and adjusting machines, performing inspections and maintenance, troubleshooting mechanical issues, and implementing preventive maintenance programs.

What are the educational requirements for becoming a Machine Adjuster?

While formal education is not always required, employers typically prefer candidates with an Associate Degree in Machine Tool Technology or a related field. Additionally, certifications in CNC programming, PLC, and hydraulics maintenance are valuable.

What are the career prospects for Machine Adjusters?

Machine Adjusters with strong skills and experience can advance to supervisory roles, such as Machine Shop Supervisor or Maintenance Manager. They can also specialize in specific areas, such as CNC programming or electrical maintenance.

What is the average salary for a Machine Adjuster?

According to the U.S. Bureau of Labor Statistics, the median annual salary for Machine Adjusters was $53,430 in May 2021. Salaries can vary depending on experience, location, and industry.

What are the essential skills for a successful Machine Adjuster?

Machine Adjusters should have a strong understanding of CNC machines, electrical and mechanical systems, and preventive maintenance practices. They should also possess excellent troubleshooting and problem-solving abilities, as well as a commitment to safety and quality.