Are you a seasoned Machine Candle Molder seeking a new career path? Discover our professionally built Machine Candle Molder Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

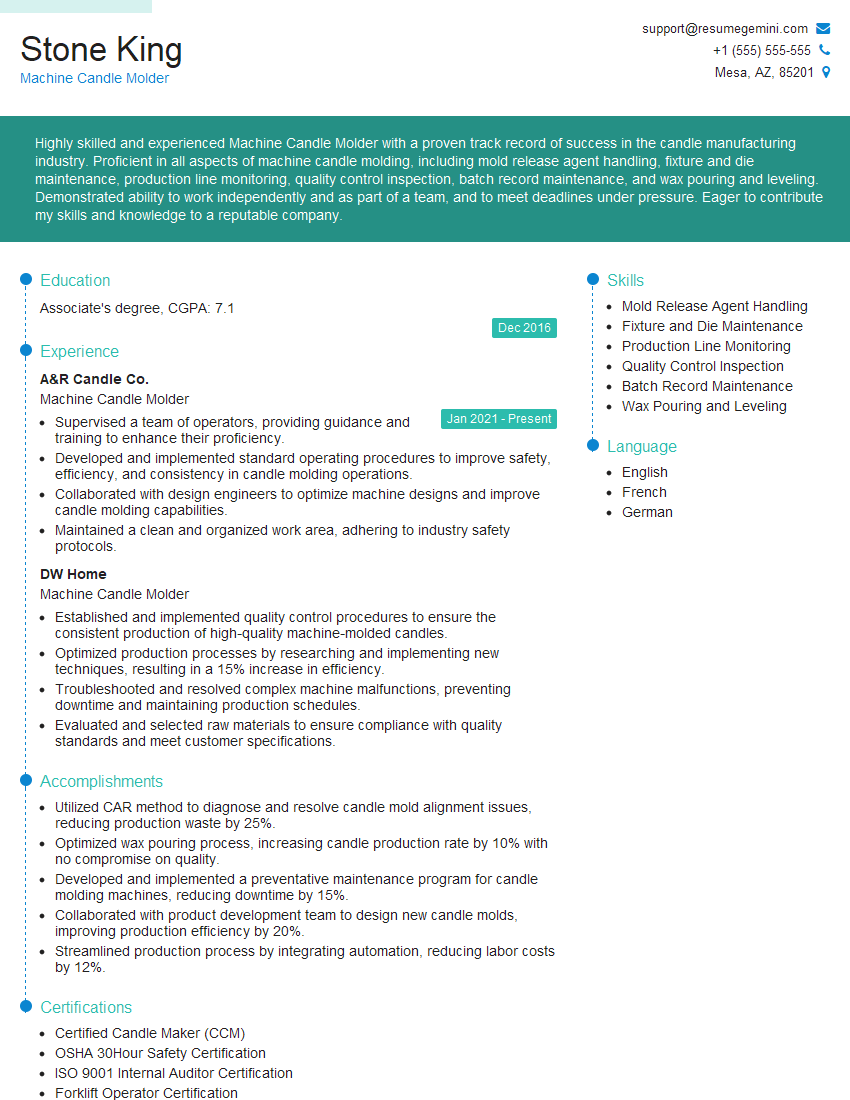

Stone King

Machine Candle Molder

Summary

Highly skilled and experienced Machine Candle Molder with a proven track record of success in the candle manufacturing industry. Proficient in all aspects of machine candle molding, including mold release agent handling, fixture and die maintenance, production line monitoring, quality control inspection, batch record maintenance, and wax pouring and leveling. Demonstrated ability to work independently and as part of a team, and to meet deadlines under pressure. Eager to contribute my skills and knowledge to a reputable company.

Education

Associate’s degree

December 2016

Skills

- Mold Release Agent Handling

- Fixture and Die Maintenance

- Production Line Monitoring

- Quality Control Inspection

- Batch Record Maintenance

- Wax Pouring and Leveling

Work Experience

Machine Candle Molder

- Supervised a team of operators, providing guidance and training to enhance their proficiency.

- Developed and implemented standard operating procedures to improve safety, efficiency, and consistency in candle molding operations.

- Collaborated with design engineers to optimize machine designs and improve candle molding capabilities.

- Maintained a clean and organized work area, adhering to industry safety protocols.

Machine Candle Molder

- Established and implemented quality control procedures to ensure the consistent production of high-quality machine-molded candles.

- Optimized production processes by researching and implementing new techniques, resulting in a 15% increase in efficiency.

- Troubleshooted and resolved complex machine malfunctions, preventing downtime and maintaining production schedules.

- Evaluated and selected raw materials to ensure compliance with quality standards and meet customer specifications.

Accomplishments

- Utilized CAR method to diagnose and resolve candle mold alignment issues, reducing production waste by 25%.

- Optimized wax pouring process, increasing candle production rate by 10% with no compromise on quality.

- Developed and implemented a preventative maintenance program for candle molding machines, reducing downtime by 15%.

- Collaborated with product development team to design new candle molds, improving production efficiency by 20%.

- Streamlined production process by integrating automation, reducing labor costs by 12%.

Certificates

- Certified Candle Maker (CCM)

- OSHA 30Hour Safety Certification

- ISO 9001 Internal Auditor Certification

- Forklift Operator Certification

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Machine Candle Molder

- Highlight your skills and experience in machine candle molding, including the specific types of machines and processes you have worked with.

- Quantify your accomplishments whenever possible. For example, state the number of candles produced or the percentage of defects reduced.

- Showcase your knowledge of candle manufacturing industry standards and regulations.

- Tailor your resume to each specific job application, highlighting the skills and experience that are most relevant to the position.

Essential Experience Highlights for a Strong Machine Candle Molder Resume

- Maintained and calibrated machine candle molding equipment to ensure optimal performance.

- Applied mold release agents to ensure easy removal of candles from molds.

- Monitored production lines to ensure smooth operation and identify potential problems.

- Inspected finished candles for defects and ensured they met quality standards.

- Maintained batch records to document production details and ensure traceability.

- Collaborated with team members to improve production efficiency and reduce downtime.

- Followed safety protocols and maintained a clean and organized work area.

Frequently Asked Questions (FAQ’s) For Machine Candle Molder

What is the typical work environment for a Machine Candle Molder?

Machine Candle Molders typically work in manufacturing facilities, where they operate and maintain candle molding machines. They may work in a team environment with other production staff, and they may also work independently.

What are the key skills required for a Machine Candle Molder?

Key skills for a Machine Candle Molder include: mold release agent handling, fixture and die maintenance, production line monitoring, quality control inspection, batch record maintenance, wax pouring and leveling.

What are the growth opportunities for a Machine Candle Molder?

Machine Candle Molders can advance to positions such as Production Supervisor or Quality Control Manager. With additional training and experience, they may also be able to move into roles in product development or machine maintenance.

What is the average salary for a Machine Candle Molder?

The average salary for a Machine Candle Molder in the United States is around $35,000 per year.

What are the job outlook prospects for a Machine Candle Molder?

The job outlook for Machine Candle Molders is expected to be good over the next few years. The demand for candles is expected to continue to grow, which will lead to increased production and the need for more Machine Candle Molders.

What are the benefits of working as a Machine Candle Molder?

Benefits of working as a Machine Candle Molder include: the opportunity to work with your hands, the satisfaction of seeing your work come to life, and the chance to work in a creative environment.