Are you a seasoned Machine Edge Bander seeking a new career path? Discover our professionally built Machine Edge Bander Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

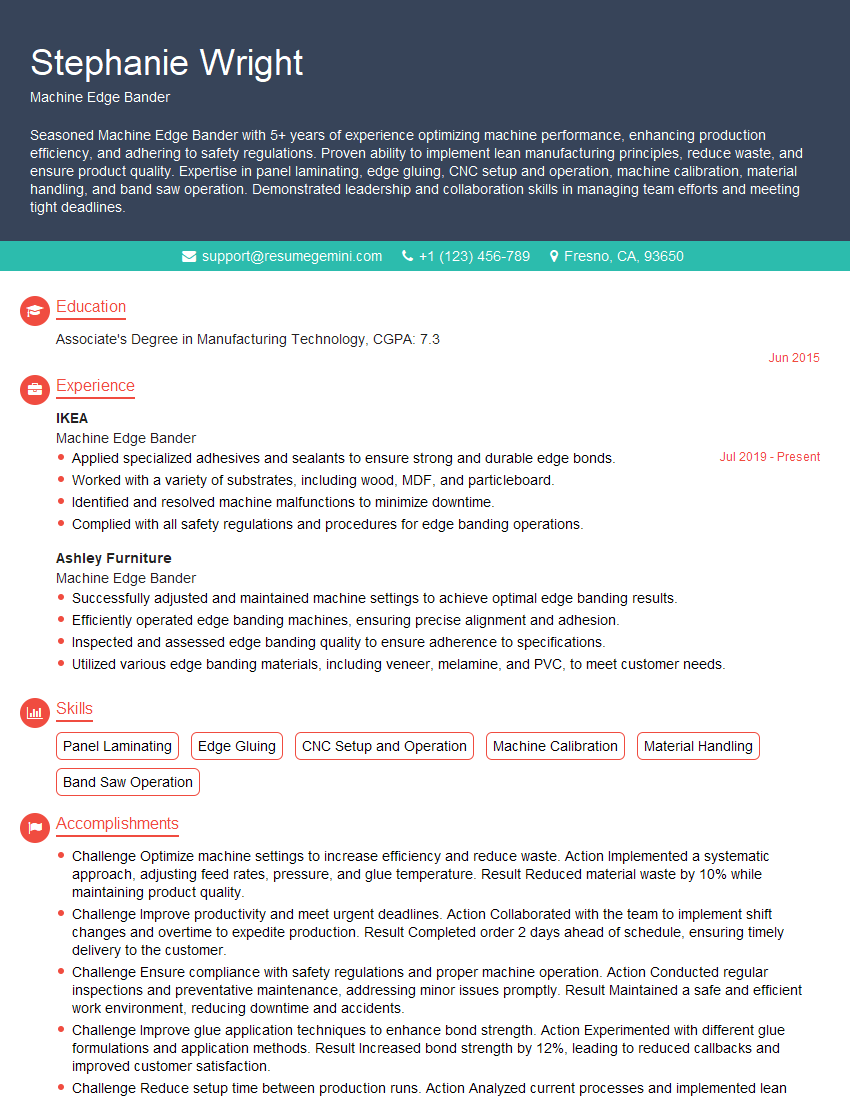

Stephanie Wright

Machine Edge Bander

Summary

Seasoned Machine Edge Bander with 5+ years of experience optimizing machine performance, enhancing production efficiency, and adhering to safety regulations. Proven ability to implement lean manufacturing principles, reduce waste, and ensure product quality. Expertise in panel laminating, edge gluing, CNC setup and operation, machine calibration, material handling, and band saw operation. Demonstrated leadership and collaboration skills in managing team efforts and meeting tight deadlines.

Education

Associate’s Degree in Manufacturing Technology

June 2015

Skills

- Panel Laminating

- Edge Gluing

- CNC Setup and Operation

- Machine Calibration

- Material Handling

- Band Saw Operation

Work Experience

Machine Edge Bander

- Applied specialized adhesives and sealants to ensure strong and durable edge bonds.

- Worked with a variety of substrates, including wood, MDF, and particleboard.

- Identified and resolved machine malfunctions to minimize downtime.

- Complied with all safety regulations and procedures for edge banding operations.

Machine Edge Bander

- Successfully adjusted and maintained machine settings to achieve optimal edge banding results.

- Efficiently operated edge banding machines, ensuring precise alignment and adhesion.

- Inspected and assessed edge banding quality to ensure adherence to specifications.

- Utilized various edge banding materials, including veneer, melamine, and PVC, to meet customer needs.

Accomplishments

- Challenge Optimize machine settings to increase efficiency and reduce waste. Action Implemented a systematic approach, adjusting feed rates, pressure, and glue temperature. Result Reduced material waste by 10% while maintaining product quality.

- Challenge Improve productivity and meet urgent deadlines. Action Collaborated with the team to implement shift changes and overtime to expedite production. Result Completed order 2 days ahead of schedule, ensuring timely delivery to the customer.

- Challenge Ensure compliance with safety regulations and proper machine operation. Action Conducted regular inspections and preventative maintenance, addressing minor issues promptly. Result Maintained a safe and efficient work environment, reducing downtime and accidents.

- Challenge Improve glue application techniques to enhance bond strength. Action Experimented with different glue formulations and application methods. Result Increased bond strength by 12%, leading to reduced callbacks and improved customer satisfaction.

- Challenge Reduce setup time between production runs. Action Analyzed current processes and implemented lean manufacturing principles. Result Reduced setup time by 15%, increasing overall production capacity.

Awards

- Recognized for producing the highest volume of edgebanded panels without defects, surpassing monthly targets by 15%.

- Awarded for maintaining a consistently high level of accuracy in edge band application, receiving positive feedback from quality control.

- Received recognition for innovation in developing a custom edgebanding solution for a complex project, exceeding customer expectations.

- Recognized for successfully troubleshooting and repairing complex machine malfunctions, ensuring uninterrupted production.

Certificates

- OSHA 30Hour Safety Certification

- First Aid and CPR Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Machine Edge Bander

- Quantify your accomplishments with specific metrics and data.

- Highlight your knowledge of lean manufacturing principles and experience in implementing them.

- Showcase your ability to work independently and as part of a team.

- Emphasize your attention to detail and commitment to safety.

Essential Experience Highlights for a Strong Machine Edge Bander Resume

- Optimize machine settings to maximize efficiency and minimize material waste.

- Conduct regular preventative maintenance and inspections to ensure smooth machine operation and minimize downtime.

- Implement lean manufacturing principles to reduce setup time and increase production capacity.

- Collaborate with team members to establish shift changes and overtime to meet urgent production deadlines.

- Supervise and train junior staff on proper machine operation and safety procedures.

Frequently Asked Questions (FAQ’s) For Machine Edge Bander

What are the key skills required for a Machine Edge Bander?

Essential skills include panel laminating, edge gluing, CNC setup and operation, machine calibration, material handling, and band saw operation.

What are the career prospects for a Machine Edge Bander?

With experience and additional training, you can advance to roles such as Production Supervisor, Quality Control Manager, or Manufacturing Engineer.

How can I improve my chances of getting hired as a Machine Edge Bander?

Obtain certification in machine operation and maintenance, gain experience in lean manufacturing, and demonstrate your ability to work efficiently and safely.

What are the safety precautions that a Machine Edge Bander should follow?

Always wear appropriate safety gear, keep the work area clean and organized, follow lockout/tagout procedures, and report any unsafe conditions immediately.

What are the common challenges faced by Machine Edge Banders?

Optimizing machine settings to minimize waste, meeting tight deadlines, ensuring product quality, adhering to safety regulations, and improving glue application techniques are some of the common challenges.