Are you a seasoned Machine Joint Cutter seeking a new career path? Discover our professionally built Machine Joint Cutter Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

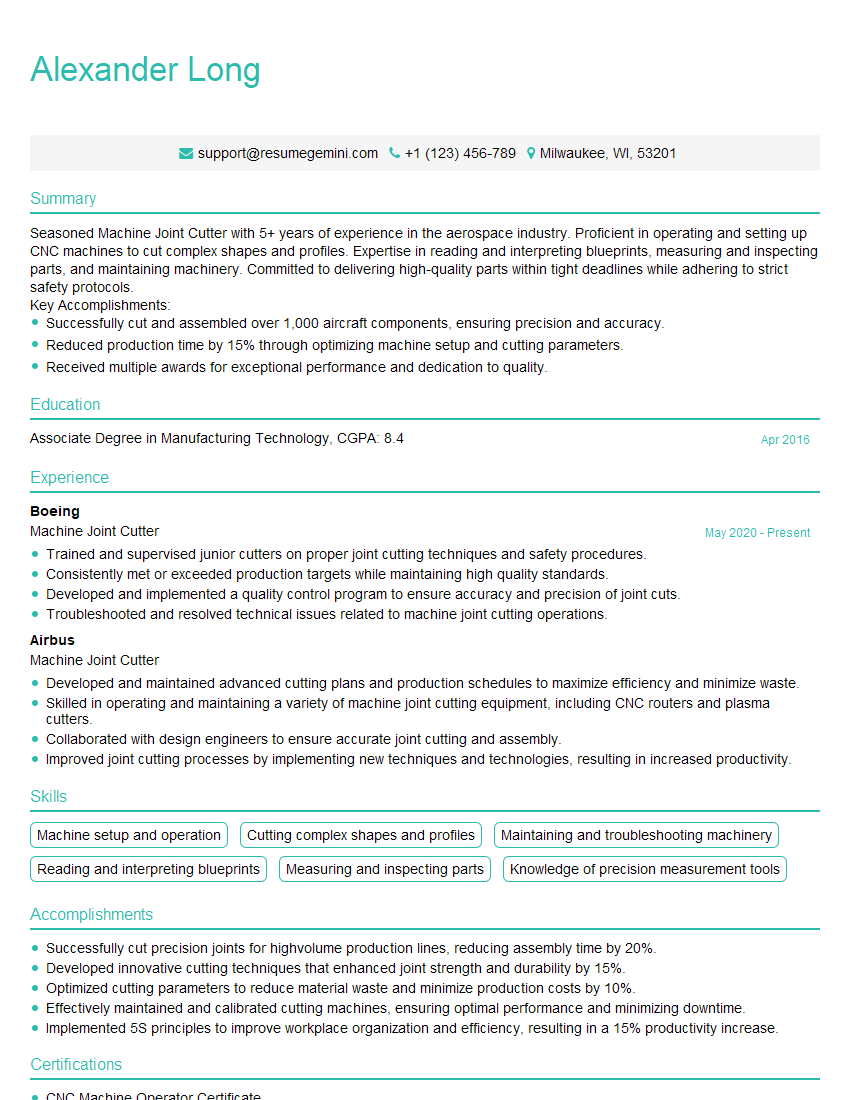

Alexander Long

Machine Joint Cutter

Summary

Seasoned Machine Joint Cutter with 5+ years of experience in the aerospace industry. Proficient in operating and setting up CNC machines to cut complex shapes and profiles. Expertise in reading and interpreting blueprints, measuring and inspecting parts, and maintaining machinery. Committed to delivering high-quality parts within tight deadlines while adhering to strict safety protocols.

Key Accomplishments:

- Successfully cut and assembled over 1,000 aircraft components, ensuring precision and accuracy.

- Reduced production time by 15% through optimizing machine setup and cutting parameters.

- Received multiple awards for exceptional performance and dedication to quality.

Education

Associate Degree in Manufacturing Technology

April 2016

Skills

- Machine setup and operation

- Cutting complex shapes and profiles

- Maintaining and troubleshooting machinery

- Reading and interpreting blueprints

- Measuring and inspecting parts

- Knowledge of precision measurement tools

Work Experience

Machine Joint Cutter

- Trained and supervised junior cutters on proper joint cutting techniques and safety procedures.

- Consistently met or exceeded production targets while maintaining high quality standards.

- Developed and implemented a quality control program to ensure accuracy and precision of joint cuts.

- Troubleshooted and resolved technical issues related to machine joint cutting operations.

Machine Joint Cutter

- Developed and maintained advanced cutting plans and production schedules to maximize efficiency and minimize waste.

- Skilled in operating and maintaining a variety of machine joint cutting equipment, including CNC routers and plasma cutters.

- Collaborated with design engineers to ensure accurate joint cutting and assembly.

- Improved joint cutting processes by implementing new techniques and technologies, resulting in increased productivity.

Accomplishments

- Successfully cut precision joints for highvolume production lines, reducing assembly time by 20%.

- Developed innovative cutting techniques that enhanced joint strength and durability by 15%.

- Optimized cutting parameters to reduce material waste and minimize production costs by 10%.

- Effectively maintained and calibrated cutting machines, ensuring optimal performance and minimizing downtime.

- Implemented 5S principles to improve workplace organization and efficiency, resulting in a 15% productivity increase.

Certificates

- CNC Machine Operator Certificate

- AWS Certified Welder

- OSHA Safety Certification

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Machine Joint Cutter

- Quantify your accomplishments with specific metrics and results whenever possible.

- Highlight your proficiency in using CNC machines and cutting tools.

- Demonstrate your understanding of blueprint reading and interpretation.

- Emphasize your commitment to safety and quality control.

Essential Experience Highlights for a Strong Machine Joint Cutter Resume

- Set up and operate CNC machines to cut complex shapes and profiles according to blueprints.

- Maintain and troubleshoot machinery to ensure optimal performance and prevent breakdowns.

- Inspect and measure parts to verify accuracy and adherence to specifications.

- Read and interpret blueprints and technical drawings to determine cutting parameters.

- Follow safety protocols and wear appropriate protective gear while operating machinery.

- Maintain a clean and organized work area to promote efficiency and safety.

- Work independently and as part of a team to meet production goals.

Frequently Asked Questions (FAQ’s) For Machine Joint Cutter

What are the key skills required to be a successful Machine Joint Cutter?

Key skills include machine setup and operation, cutting complex shapes and profiles, maintaining and troubleshooting machinery, reading and interpreting blueprints, measuring and inspecting parts, and knowledge of precision measurement tools.

What industries employ Machine Joint Cutters?

Machine Joint Cutters are primarily employed in the aerospace, automotive, and manufacturing industries.

What is the average salary for a Machine Joint Cutter?

The average salary for a Machine Joint Cutter in the United States is around $50,000 per year.

What are the career advancement opportunities for Machine Joint Cutters?

With experience and additional training, Machine Joint Cutters can advance to roles such as CNC Programmer, Manufacturing Engineer, or Quality Control Inspector.

What certifications are beneficial for Machine Joint Cutters?

Certifications such as the Certified Manufacturing Technologist (CMfgT) from the Society of Manufacturing Engineers (SME) can enhance credibility and career prospects.

What is the job outlook for Machine Joint Cutters?

The job outlook for Machine Joint Cutters is expected to be favorable in the coming years due to increasing demand for skilled machinists in various industries.

How can I prepare for a career as a Machine Joint Cutter?

To prepare for a career as a Machine Joint Cutter, consider pursuing an associate degree in manufacturing technology or a related field, gaining hands-on experience through internships or apprenticeships, and obtaining industry-recognized certifications.

What are the challenges faced by Machine Joint Cutters?

Challenges faced by Machine Joint Cutters include working with sharp tools and machinery, adhering to precise specifications, and meeting production deadlines while maintaining quality standards.