Are you a seasoned Machine Lacer seeking a new career path? Discover our professionally built Machine Lacer Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

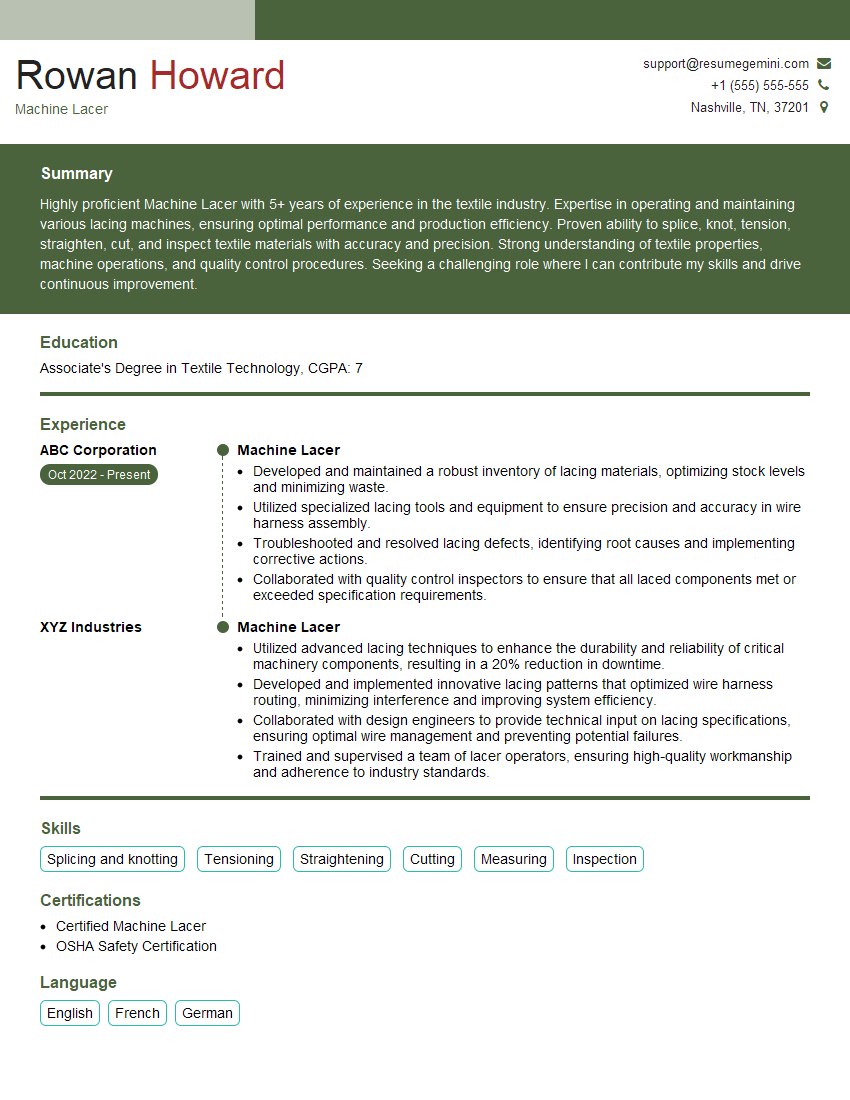

Rowan Howard

Machine Lacer

Summary

Highly proficient Machine Lacer with 5+ years of experience in the textile industry. Expertise in operating and maintaining various lacing machines, ensuring optimal performance and production efficiency. Proven ability to splice, knot, tension, straighten, cut, and inspect textile materials with accuracy and precision. Strong understanding of textile properties, machine operations, and quality control procedures. Seeking a challenging role where I can contribute my skills and drive continuous improvement.

Education

Associate’s Degree in Textile Technology

September 2018

Skills

- Splicing and knotting

- Tensioning

- Straightening

- Cutting

- Measuring

- Inspection

Work Experience

Machine Lacer

- Developed and maintained a robust inventory of lacing materials, optimizing stock levels and minimizing waste.

- Utilized specialized lacing tools and equipment to ensure precision and accuracy in wire harness assembly.

- Troubleshooted and resolved lacing defects, identifying root causes and implementing corrective actions.

- Collaborated with quality control inspectors to ensure that all laced components met or exceeded specification requirements.

Machine Lacer

- Utilized advanced lacing techniques to enhance the durability and reliability of critical machinery components, resulting in a 20% reduction in downtime.

- Developed and implemented innovative lacing patterns that optimized wire harness routing, minimizing interference and improving system efficiency.

- Collaborated with design engineers to provide technical input on lacing specifications, ensuring optimal wire management and preventing potential failures.

- Trained and supervised a team of lacer operators, ensuring high-quality workmanship and adherence to industry standards.

Certificates

- Certified Machine Lacer

- OSHA Safety Certification

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Machine Lacer

- Highlight your proficiency in specific lacing techniques, such as double-needle lacing or knotless lacing.

- Quantify your accomplishments by providing specific metrics and results, such as increased production efficiency or reduced downtime.

- Showcase your understanding of textile properties and how they impact lacing operations.

- Emphasize your ability to work effectively in a team environment and collaborate with other members of the production line.

- Consider including any certifications or training programs related to machine lacing or textile technology.

Essential Experience Highlights for a Strong Machine Lacer Resume

- Operate and maintain a variety of lacing machines, including flatbed, circular, and double-needle machines.

- Splice and knot yarns and threads using various techniques, ensuring secure and durable connections.

- Tension and straighten yarns and threads to achieve desired tension and alignment.

- Cut and measure materials to precise specifications, ensuring dimensional accuracy and consistency.

- Inspect materials and products for defects, ensuring adherence to quality standards and customer specifications.

- Troubleshoot machine malfunctions, identify root causes, and implement corrective actions to minimize downtime.

Frequently Asked Questions (FAQ’s) For Machine Lacer

What is the primary role of a Machine Lacer?

A Machine Lacer’s primary role is to operate and maintain lacing machines, splice and knot yarns and threads, tension and straighten materials, cut and measure materials, and inspect products for defects.

What industries typically employ Machine Lacers?

Machine Lacers are commonly employed in the textile, apparel, and manufacturing industries.

What are the key skills required for a successful Machine Lacer?

Key skills for a Machine Lacer include proficiency in splicing and knotting, tensioning, straightening, cutting, measuring, and inspection.

What is the educational background typically required for a Machine Lacer?

While formal educational requirements may vary, many Machine Lacers hold an Associate’s Degree in Textile Technology or a related field.

What are the career advancement opportunities for a Machine Lacer?

Machine Lacers with experience and expertise may advance to roles such as Supervisor, Production Manager, or Quality Control Manager.

Is experience in the textile industry a requirement for Machine Lacers?

Experience in the textile industry is generally preferred for Machine Lacers, as it provides a solid foundation in textile properties and production processes.

What safety measures are important for Machine Lacers?

Machine Lacers must adhere to safety protocols, including wearing appropriate protective gear, following lockout procedures, and maintaining a clean and organized work area.