Are you a seasoned Machine Rough Rounder seeking a new career path? Discover our professionally built Machine Rough Rounder Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

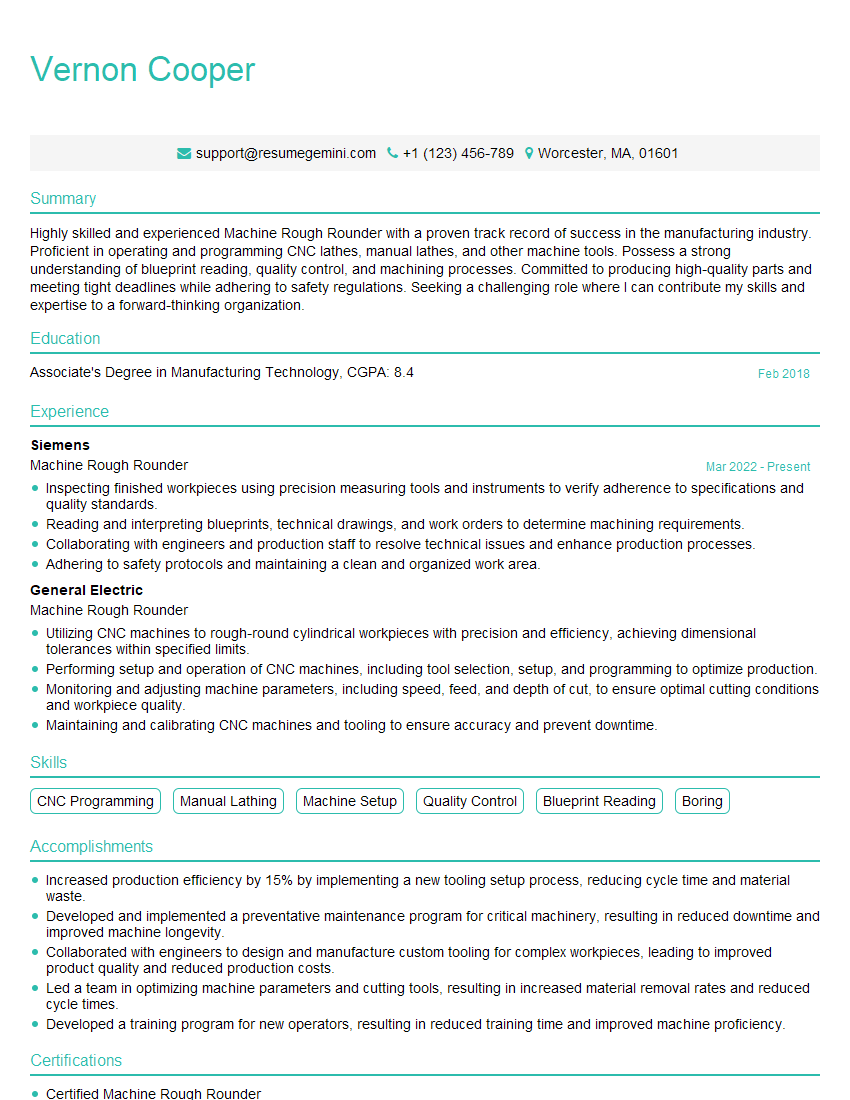

Vernon Cooper

Machine Rough Rounder

Summary

Highly skilled and experienced Machine Rough Rounder with a proven track record of success in the manufacturing industry. Proficient in operating and programming CNC lathes, manual lathes, and other machine tools. Possess a strong understanding of blueprint reading, quality control, and machining processes. Committed to producing high-quality parts and meeting tight deadlines while adhering to safety regulations. Seeking a challenging role where I can contribute my skills and expertise to a forward-thinking organization.

Education

Associate’s Degree in Manufacturing Technology

February 2018

Skills

- CNC Programming

- Manual Lathing

- Machine Setup

- Quality Control

- Blueprint Reading

- Boring

Work Experience

Machine Rough Rounder

- Inspecting finished workpieces using precision measuring tools and instruments to verify adherence to specifications and quality standards.

- Reading and interpreting blueprints, technical drawings, and work orders to determine machining requirements.

- Collaborating with engineers and production staff to resolve technical issues and enhance production processes.

- Adhering to safety protocols and maintaining a clean and organized work area.

Machine Rough Rounder

- Utilizing CNC machines to rough-round cylindrical workpieces with precision and efficiency, achieving dimensional tolerances within specified limits.

- Performing setup and operation of CNC machines, including tool selection, setup, and programming to optimize production.

- Monitoring and adjusting machine parameters, including speed, feed, and depth of cut, to ensure optimal cutting conditions and workpiece quality.

- Maintaining and calibrating CNC machines and tooling to ensure accuracy and prevent downtime.

Accomplishments

- Increased production efficiency by 15% by implementing a new tooling setup process, reducing cycle time and material waste.

- Developed and implemented a preventative maintenance program for critical machinery, resulting in reduced downtime and improved machine longevity.

- Collaborated with engineers to design and manufacture custom tooling for complex workpieces, leading to improved product quality and reduced production costs.

- Led a team in optimizing machine parameters and cutting tools, resulting in increased material removal rates and reduced cycle times.

- Developed a training program for new operators, resulting in reduced training time and improved machine proficiency.

Certificates

- Certified Machine Rough Rounder

- OSHA 30Hour Safety Training Certification

- ISO 90012015 Quality Management System Certification

- Lean Six Sigma Certification

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Machine Rough Rounder

- Highlight your CNC programming skills and experience in your resume.

- Quantify your accomplishments whenever possible, using specific numbers and metrics.

- Use industry-specific keywords throughout your resume to optimize it for search engines.

- Proofread your resume carefully before submitting it to eliminate any errors.

- Consider including a portfolio of your work to showcase your skills.

Essential Experience Highlights for a Strong Machine Rough Rounder Resume

- Operate and program CNC lathes, manual lathes, and other machine tools to produce precision parts according to specifications.

- Read and interpret blueprints, technical drawings, and work orders to determine machining requirements.

- Perform quality control checks on finished parts to ensure they meet specifications and customer requirements.

- Set up and maintain machine tools, including changing cutting tools, adjusting speeds and feeds, and lubricating moving parts.

- Troubleshoot and resolve machine problems to minimize downtime and maintain production efficiency.

- Follow safety protocols and maintain a clean and organized work area.

- Work independently and as part of a team to meet production targets and deadlines.

Frequently Asked Questions (FAQ’s) For Machine Rough Rounder

What is the primary role of a Machine Rough Rounder?

The primary role of a Machine Rough Rounder is to operate and program machine tools, such as CNC lathes and manual lathes, to produce precision parts according to specifications. They are responsible for reading and interpreting blueprints, setting up and maintaining machine tools, performing quality control checks, and troubleshooting machine problems.

What skills are required to become a Machine Rough Rounder?

To become a Machine Rough Rounder, you typically need an Associate’s Degree in Manufacturing Technology or a related field, as well as experience in operating and programming CNC lathes and manual lathes. Additional skills include blueprint reading, quality control, and machining processes.

What is the job outlook for Machine Rough Rounders?

The job outlook for Machine Rough Rounders is expected to be good in the coming years due to the increasing demand for precision parts in various industries, such as automotive, aerospace, and medical.

What are the career advancement opportunities for Machine Rough Rounders?

Machine Rough Rounders can advance their careers by becoming CNC programmers, quality control inspectors, or supervisors. With additional training and experience, they can also move into management roles.

What are the safety precautions that Machine Rough Rounders must follow?

Machine Rough Rounders must follow strict safety precautions, such as wearing appropriate personal protective equipment, following lockout/tagout procedures, and maintaining a clean and organized work area. They must also be aware of the potential hazards associated with operating machine tools and take steps to minimize risks.