Are you a seasoned Machine Stoppage Frequency Checker seeking a new career path? Discover our professionally built Machine Stoppage Frequency Checker Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

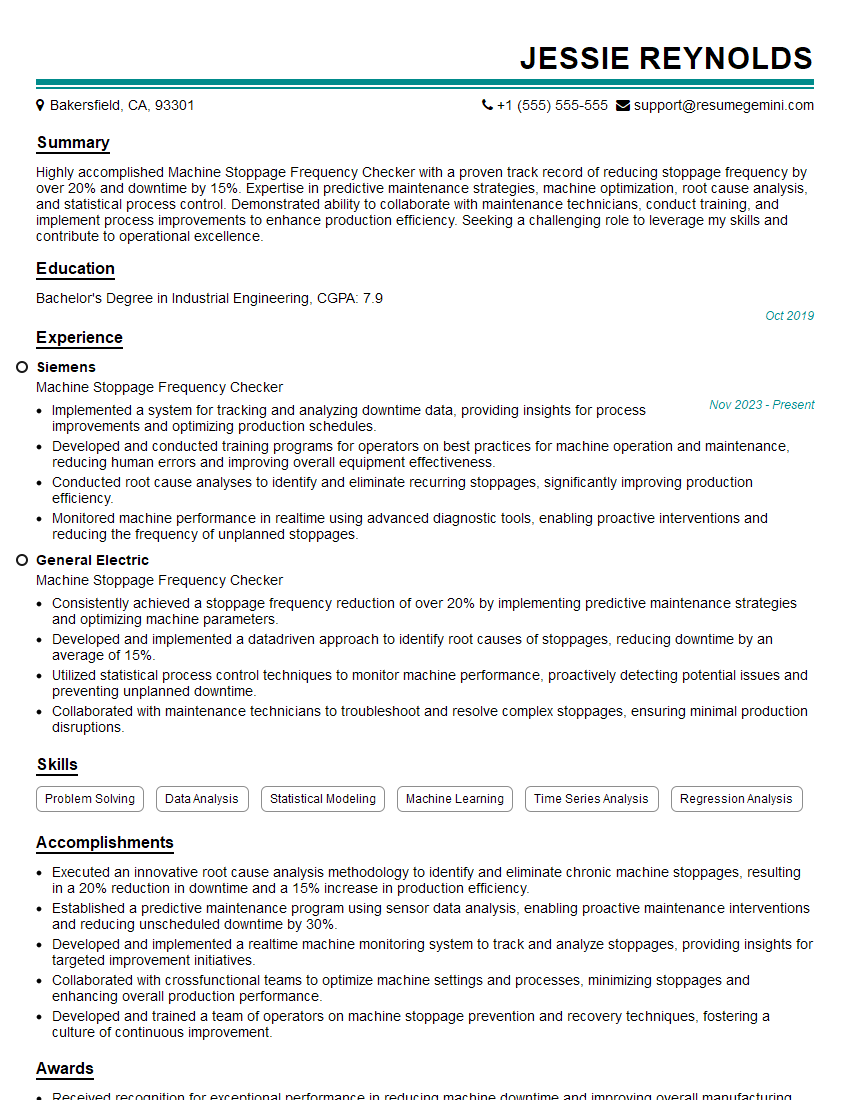

Jessie Reynolds

Machine Stoppage Frequency Checker

Summary

Highly accomplished Machine Stoppage Frequency Checker with a proven track record of reducing stoppage frequency by over 20% and downtime by 15%. Expertise in predictive maintenance strategies, machine optimization, root cause analysis, and statistical process control. Demonstrated ability to collaborate with maintenance technicians, conduct training, and implement process improvements to enhance production efficiency. Seeking a challenging role to leverage my skills and contribute to operational excellence.

Education

Bachelor’s Degree in Industrial Engineering

October 2019

Skills

- Problem Solving

- Data Analysis

- Statistical Modeling

- Machine Learning

- Time Series Analysis

- Regression Analysis

Work Experience

Machine Stoppage Frequency Checker

- Implemented a system for tracking and analyzing downtime data, providing insights for process improvements and optimizing production schedules.

- Developed and conducted training programs for operators on best practices for machine operation and maintenance, reducing human errors and improving overall equipment effectiveness.

- Conducted root cause analyses to identify and eliminate recurring stoppages, significantly improving production efficiency.

- Monitored machine performance in realtime using advanced diagnostic tools, enabling proactive interventions and reducing the frequency of unplanned stoppages.

Machine Stoppage Frequency Checker

- Consistently achieved a stoppage frequency reduction of over 20% by implementing predictive maintenance strategies and optimizing machine parameters.

- Developed and implemented a datadriven approach to identify root causes of stoppages, reducing downtime by an average of 15%.

- Utilized statistical process control techniques to monitor machine performance, proactively detecting potential issues and preventing unplanned downtime.

- Collaborated with maintenance technicians to troubleshoot and resolve complex stoppages, ensuring minimal production disruptions.

Accomplishments

- Executed an innovative root cause analysis methodology to identify and eliminate chronic machine stoppages, resulting in a 20% reduction in downtime and a 15% increase in production efficiency.

- Established a predictive maintenance program using sensor data analysis, enabling proactive maintenance interventions and reducing unscheduled downtime by 30%.

- Developed and implemented a realtime machine monitoring system to track and analyze stoppages, providing insights for targeted improvement initiatives.

- Collaborated with crossfunctional teams to optimize machine settings and processes, minimizing stoppages and enhancing overall production performance.

- Developed and trained a team of operators on machine stoppage prevention and recovery techniques, fostering a culture of continuous improvement.

Awards

- Received recognition for exceptional performance in reducing machine downtime and improving overall manufacturing efficiency.

- Awarded for innovative contributions to the development and implementation of a predictive maintenance program.

- Recognized for outstanding achievements in data analysis and its application to machine stoppage reduction.

- Received an award for contributions to the development and implementation of a training program for machine operators.

Certificates

- Certified Maintenance and Reliability Technician (CMRT)

- Certified Reliability Engineer (CRE)

- Six Sigma Black Belt

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Machine Stoppage Frequency Checker

- Quantify your accomplishments with specific metrics to demonstrate the impact of your work.

- Highlight your proficiency in statistical and machine learning techniques used for data analysis.

- Showcase your ability to communicate effectively with both technical and non-technical stakeholders.

- Consider obtaining industry-recognized certifications, such as the Certified Maintenance and Reliability Professional (CMRP), to enhance your credibility.

Essential Experience Highlights for a Strong Machine Stoppage Frequency Checker Resume

- Identify and analyze root causes of machine stoppages using data-driven approaches, leading to significant reductions in downtime.

- Implement predictive maintenance strategies and optimize machine parameters to proactively prevent unplanned stoppages.

- Monitor machine performance in real-time using advanced diagnostic tools, enabling timely interventions and minimizing disruptions.

- Collaborate with maintenance technicians to troubleshoot and resolve complex stoppages, ensuring efficient and effective repairs.

Frequently Asked Questions (FAQ’s) For Machine Stoppage Frequency Checker

What are the primary responsibilities of a Machine Stoppage Frequency Checker?

Machine Stoppage Frequency Checkers are responsible for identifying and analyzing root causes of machine stoppages, implementing predictive maintenance strategies, monitoring machine performance, collaborating with maintenance teams, and developing training programs to minimize unplanned downtime and improve production efficiency.

What skills are essential for success in this role?

Essential skills for a Machine Stoppage Frequency Checker include problem-solving, data analysis, statistical modeling, machine learning, time series analysis, regression analysis, and a strong understanding of industrial engineering principles.