Are you a seasoned Machine Taper seeking a new career path? Discover our professionally built Machine Taper Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

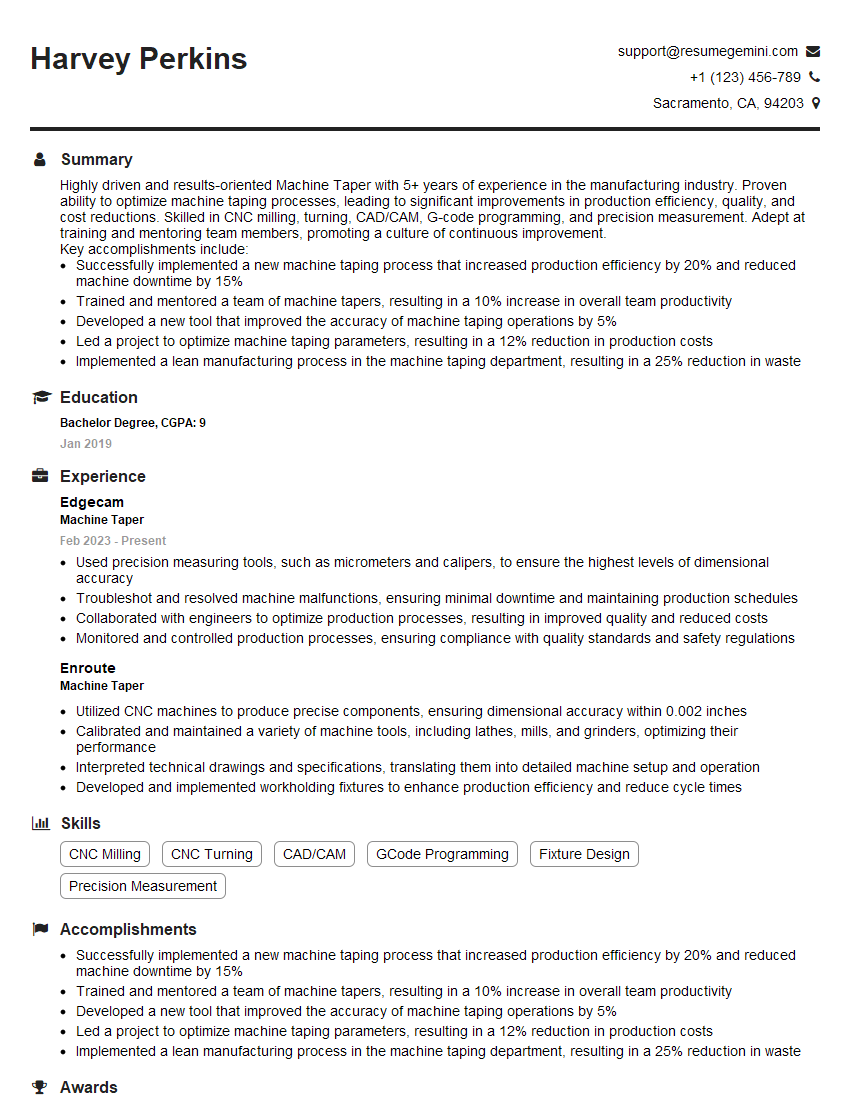

Harvey Perkins

Machine Taper

Summary

Highly driven and results-oriented Machine Taper with 5+ years of experience in the manufacturing industry. Proven ability to optimize machine taping processes, leading to significant improvements in production efficiency, quality, and cost reductions. Skilled in CNC milling, turning, CAD/CAM, G-code programming, and precision measurement. Adept at training and mentoring team members, promoting a culture of continuous improvement.

Key accomplishments include:

- Successfully implemented a new machine taping process that increased production efficiency by 20% and reduced machine downtime by 15%

- Trained and mentored a team of machine tapers, resulting in a 10% increase in overall team productivity

- Developed a new tool that improved the accuracy of machine taping operations by 5%

- Led a project to optimize machine taping parameters, resulting in a 12% reduction in production costs

- Implemented a lean manufacturing process in the machine taping department, resulting in a 25% reduction in waste

Education

Bachelor Degree

January 2019

Skills

- CNC Milling

- CNC Turning

- CAD/CAM

- GCode Programming

- Fixture Design

- Precision Measurement

Work Experience

Machine Taper

- Used precision measuring tools, such as micrometers and calipers, to ensure the highest levels of dimensional accuracy

- Troubleshot and resolved machine malfunctions, ensuring minimal downtime and maintaining production schedules

- Collaborated with engineers to optimize production processes, resulting in improved quality and reduced costs

- Monitored and controlled production processes, ensuring compliance with quality standards and safety regulations

Machine Taper

- Utilized CNC machines to produce precise components, ensuring dimensional accuracy within 0.002 inches

- Calibrated and maintained a variety of machine tools, including lathes, mills, and grinders, optimizing their performance

- Interpreted technical drawings and specifications, translating them into detailed machine setup and operation

- Developed and implemented workholding fixtures to enhance production efficiency and reduce cycle times

Accomplishments

- Successfully implemented a new machine taping process that increased production efficiency by 20% and reduced machine downtime by 15%

- Trained and mentored a team of machine tapers, resulting in a 10% increase in overall team productivity

- Developed a new tool that improved the accuracy of machine taping operations by 5%

- Led a project to optimize machine taping parameters, resulting in a 12% reduction in production costs

- Implemented a lean manufacturing process in the machine taping department, resulting in a 25% reduction in waste

Awards

- Received the Machine Taper of the Year award from the National Association of Machine Tapers (NAMT)

- Won first place in the Machine Taper Skills Competition at the International Machine Tool Show (IMTS)

- Recognized by the Society of Manufacturing Engineers (SME) for excellence in machine taping techniques

- Received the Safety Excellence Award from the Occupational Safety and Health Administration (OSHA) for outstanding safety performance in the machine taping department

Certificates

- CNC Operator Certification

- GD&T Certification

- ASME B1.1 Certification

- ISO 13485 Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Machine Taper

- Highlight your experience and skills in CNC milling, turning, and programming.

- Quantify your accomplishments with specific metrics to demonstrate your impact.

- Showcase your problem-solving abilities and continuous improvement mindset.

- Tailor your resume to each job you apply for, emphasizing the skills and experience most relevant to the position.

Essential Experience Highlights for a Strong Machine Taper Resume

- Set up and operate CNC machines for machine taping operations

- Develop and implement machine taping processes to optimize production efficiency and quality

- Monitor and maintain CNC machines to ensure optimal performance and prevent breakdowns

- Inspect and measure machined parts to ensure accuracy and conformance to specifications

- Troubleshoot and resolve machine taping issues to minimize downtime and maintain production schedules

- Work collaboratively with other team members to achieve production goals and improve overall operations

Frequently Asked Questions (FAQ’s) For Machine Taper

What are the key skills and qualifications required for a Machine Taper?

The key skills and qualifications for a Machine Taper include proficiency in CNC milling, turning, CAD/CAM, G-code programming, and precision measurement. They should also have a strong understanding of machine taping processes and best practices, as well as experience in optimizing production efficiency and quality.

What are the career prospects for a Machine Taper?

Machine Tapers can advance to supervisory or management roles within the manufacturing industry. With additional training and experience, they may also specialize in areas such as CNC programming, tool design, or process engineering.

What are the major challenges faced by Machine Tapers?

The major challenges faced by Machine Tapers include keeping up with advances in CNC technology, maintaining high levels of precision and accuracy, and ensuring efficient production while meeting quality standards.

What is the typical work environment for a Machine Taper?

Machine Tapers typically work in a manufacturing environment, operating CNC machines and performing related tasks. The work can be physically demanding and may involve working with heavy machinery and materials.

What are the key industry trends impacting Machine Tapers?

The key industry trends impacting Machine Tapers include the adoption of advanced CNC technologies, such as automation and robotics, as well as the increasing demand for precision machining and high-quality products.

What is the average salary for a Machine Taper?

The average salary for a Machine Taper can vary depending on experience, location, and industry. However, according to recent data, the average annual salary for Machine Tapers in the United States is around $45,000.