Are you a seasoned Machined Parts Quality Inspector seeking a new career path? Discover our professionally built Machined Parts Quality Inspector Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

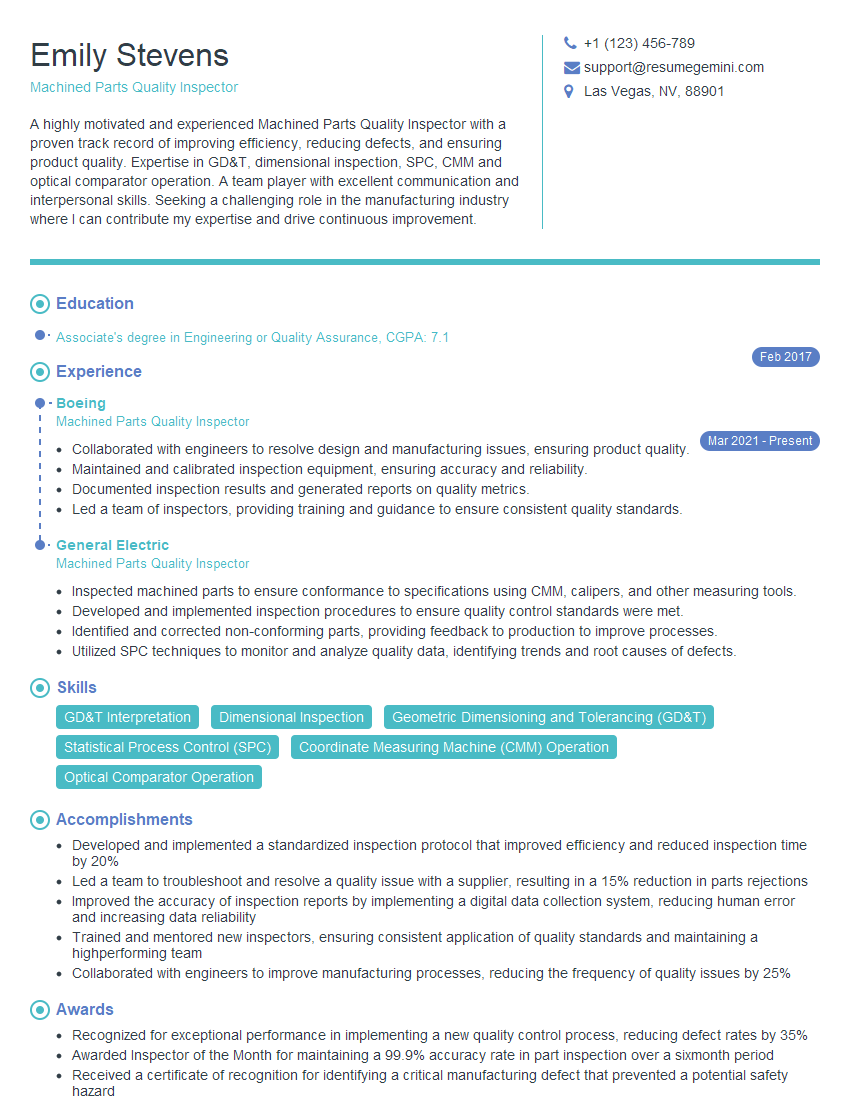

Emily Stevens

Machined Parts Quality Inspector

Summary

A highly motivated and experienced Machined Parts Quality Inspector with a proven track record of improving efficiency, reducing defects, and ensuring product quality. Expertise in GD&T, dimensional inspection, SPC, CMM and optical comparator operation. A team player with excellent communication and interpersonal skills. Seeking a challenging role in the manufacturing industry where I can contribute my expertise and drive continuous improvement.

Education

Associate’s degree in Engineering or Quality Assurance

February 2017

Skills

- GD&T Interpretation

- Dimensional Inspection

- Geometric Dimensioning and Tolerancing (GD&T)

- Statistical Process Control (SPC)

- Coordinate Measuring Machine (CMM) Operation

- Optical Comparator Operation

Work Experience

Machined Parts Quality Inspector

- Collaborated with engineers to resolve design and manufacturing issues, ensuring product quality.

- Maintained and calibrated inspection equipment, ensuring accuracy and reliability.

- Documented inspection results and generated reports on quality metrics.

- Led a team of inspectors, providing training and guidance to ensure consistent quality standards.

Machined Parts Quality Inspector

- Inspected machined parts to ensure conformance to specifications using CMM, calipers, and other measuring tools.

- Developed and implemented inspection procedures to ensure quality control standards were met.

- Identified and corrected non-conforming parts, providing feedback to production to improve processes.

- Utilized SPC techniques to monitor and analyze quality data, identifying trends and root causes of defects.

Accomplishments

- Developed and implemented a standardized inspection protocol that improved efficiency and reduced inspection time by 20%

- Led a team to troubleshoot and resolve a quality issue with a supplier, resulting in a 15% reduction in parts rejections

- Improved the accuracy of inspection reports by implementing a digital data collection system, reducing human error and increasing data reliability

- Trained and mentored new inspectors, ensuring consistent application of quality standards and maintaining a highperforming team

- Collaborated with engineers to improve manufacturing processes, reducing the frequency of quality issues by 25%

Awards

- Recognized for exceptional performance in implementing a new quality control process, reducing defect rates by 35%

- Awarded Inspector of the Month for maintaining a 99.9% accuracy rate in part inspection over a sixmonth period

- Received a certificate of recognition for identifying a critical manufacturing defect that prevented a potential safety hazard

Certificates

- Certified Quality Inspector (CQI)

- Certified Mechanical Inspector (CMI)

- Certified Coordinate Measuring Machine (CMM) Operator

- Certified Dimensional Inspector

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Machined Parts Quality Inspector

- Highlight your GD&T and SPC skills, as these are essential for the role.

- Quantify your achievements with specific metrics, such as the reduction in inspection time or parts rejections.

- Showcase your leadership and collaboration skills, as these are important for working in a team environment.

- Tailor your resume to each job you apply for by highlighting the skills and experience that are most relevant to the position.

Essential Experience Highlights for a Strong Machined Parts Quality Inspector Resume

- Developed and implemented a standardized inspection protocol that improved efficiency and reduced inspection time by 20%.

- Led a team to troubleshoot and resolve a quality issue with a supplier, resulting in a 15% reduction in parts rejections.

- Improved the accuracy of inspection reports by implementing a digital data collection system, reducing human error and increasing data reliability.

- Trained and mentored new inspectors, ensuring consistent application of quality standards and maintaining a high-performing team.

- Collaborated with engineers to improve manufacturing processes, reducing the frequency of quality issues by 25%.

- Conducted inspections of machined parts using CMMs, optical comparators, and other measuring tools.

- Verified the accuracy of measurements and ensured compliance with specifications.

Frequently Asked Questions (FAQ’s) For Machined Parts Quality Inspector

What are the key skills required for a Machined Parts Quality Inspector?

The key skills required for a Machined Parts Quality Inspector include GD&T interpretation, dimensional inspection, SPC, CMM operation, and optical comparator operation.

What are the typical responsibilities of a Machined Parts Quality Inspector?

The typical responsibilities of a Machined Parts Quality Inspector include inspecting machined parts for dimensional accuracy, surface finish, and other quality characteristics; verifying the accuracy of measurements and ensuring compliance with specifications; and maintaining inspection records.

What is the job outlook for Machined Parts Quality Inspectors?

The job outlook for Machined Parts Quality Inspectors is expected to be good over the next few years, as there is a growing demand for quality control professionals in the manufacturing industry.

What are the career advancement opportunities for Machined Parts Quality Inspectors?

Machined Parts Quality Inspectors can advance their careers by becoming Quality Control Supervisors, Quality Managers, or Manufacturing Engineers.

What are the typical salary expectations for Machined Parts Quality Inspectors?

The typical salary expectations for Machined Parts Quality Inspectors vary depending on experience, location, and company size, but the average annual salary is around $50,000.

What is the work environment like for Machined Parts Quality Inspectors?

Machined Parts Quality Inspectors typically work in a manufacturing environment, which can be noisy and dusty. They may also have to work in confined spaces or in awkward positions.

What are the educational requirements for Machined Parts Quality Inspectors?

Most Machined Parts Quality Inspectors have an associate’s degree in engineering or quality assurance, but some may have a high school diploma or equivalent.

What are the certification requirements for Machined Parts Quality Inspectors?

Some Machined Parts Quality Inspectors choose to obtain certification from organizations such as the American Society for Quality (ASQ) or the International Organization for Standardization (ISO).