Are you a seasoned Machinery Repair Maintenance Supervisor seeking a new career path? Discover our professionally built Machinery Repair Maintenance Supervisor Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

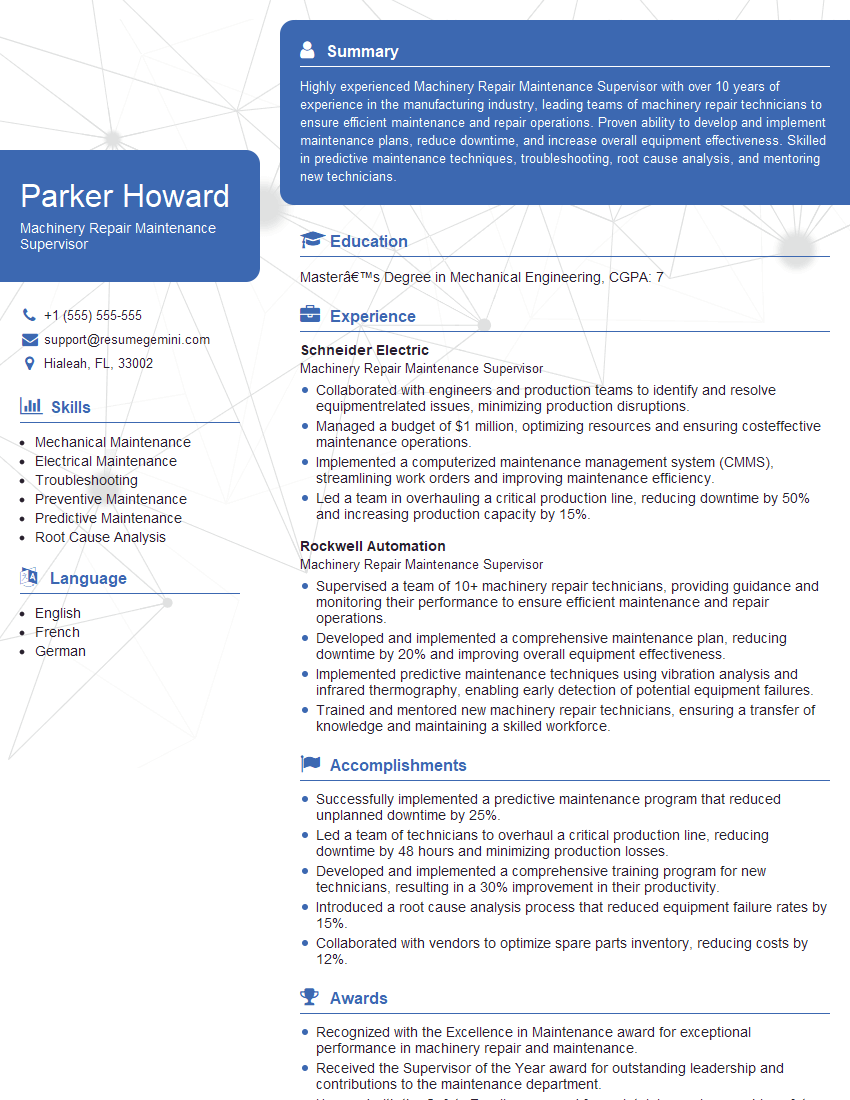

Parker Howard

Machinery Repair Maintenance Supervisor

Summary

Highly experienced Machinery Repair Maintenance Supervisor with over 10 years of experience in the manufacturing industry, leading teams of machinery repair technicians to ensure efficient maintenance and repair operations. Proven ability to develop and implement maintenance plans, reduce downtime, and increase overall equipment effectiveness. Skilled in predictive maintenance techniques, troubleshooting, root cause analysis, and mentoring new technicians.

Education

Master’s Degree in Mechanical Engineering

September 2015

Skills

- Mechanical Maintenance

- Electrical Maintenance

- Troubleshooting

- Preventive Maintenance

- Predictive Maintenance

- Root Cause Analysis

Work Experience

Machinery Repair Maintenance Supervisor

- Collaborated with engineers and production teams to identify and resolve equipmentrelated issues, minimizing production disruptions.

- Managed a budget of $1 million, optimizing resources and ensuring costeffective maintenance operations.

- Implemented a computerized maintenance management system (CMMS), streamlining work orders and improving maintenance efficiency.

- Led a team in overhauling a critical production line, reducing downtime by 50% and increasing production capacity by 15%.

Machinery Repair Maintenance Supervisor

- Supervised a team of 10+ machinery repair technicians, providing guidance and monitoring their performance to ensure efficient maintenance and repair operations.

- Developed and implemented a comprehensive maintenance plan, reducing downtime by 20% and improving overall equipment effectiveness.

- Implemented predictive maintenance techniques using vibration analysis and infrared thermography, enabling early detection of potential equipment failures.

- Trained and mentored new machinery repair technicians, ensuring a transfer of knowledge and maintaining a skilled workforce.

Accomplishments

- Successfully implemented a predictive maintenance program that reduced unplanned downtime by 25%.

- Led a team of technicians to overhaul a critical production line, reducing downtime by 48 hours and minimizing production losses.

- Developed and implemented a comprehensive training program for new technicians, resulting in a 30% improvement in their productivity.

- Introduced a root cause analysis process that reduced equipment failure rates by 15%.

- Collaborated with vendors to optimize spare parts inventory, reducing costs by 12%.

Awards

- Recognized with the Excellence in Maintenance award for exceptional performance in machinery repair and maintenance.

- Received the Supervisor of the Year award for outstanding leadership and contributions to the maintenance department.

- Honored with the Safety Excellence award for maintaining an impeccable safety record in the workshop.

- Recognized for achieving the companys highest customer satisfaction ratings for maintenance services.

Certificates

- Certified Maintenance and Reliability Professional (CMRP)

- Certified Maintenance Manager (CMM)

- Certified Plant Maintenance Manager (CPMM)

- Certified Machine Repair Mechanic (CMRM)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Machinery Repair Maintenance Supervisor

- Highlight your experience in leading and supervising a team of machinery repair technicians.

- Quantify your accomplishments with specific metrics, such as reducing downtime by 20% or improving overall equipment effectiveness by 15%.

- Showcase your knowledge of predictive maintenance techniques, such as vibration analysis and infrared thermography.

- Emphasize your ability to collaborate with engineers and production teams to resolve equipmentrelated issues.

- Demonstrate your commitment to continuous improvement by highlighting your role in implementing a computerized maintenance management system (CMMS) or other initiatives to streamline operations.

Essential Experience Highlights for a Strong Machinery Repair Maintenance Supervisor Resume

- Supervise a team of machinery repair technicians to ensure efficient maintenance and repair operations.

- Develop and implement a comprehensive maintenance plan to reduce downtime and improve overall equipment effectiveness.

- Implement predictive maintenance techniques to enable early detection of potential equipment failures.

- Train and mentor new machinery repair technicians to maintain a skilled workforce.

- Collaborate with engineers and production teams to identify and resolve equipmentrelated issues, minimizing production disruptions.

- Optimize resources and ensure cost-effective maintenance operations by managing a budget of $1 million.

- Utilize a computerized maintenance management system (CMMS) to streamline work orders and improve maintenance efficiency.

Frequently Asked Questions (FAQ’s) For Machinery Repair Maintenance Supervisor

What are the key skills and qualifications required for a Machinery Repair Maintenance Supervisor?

The key skills and qualifications required for a Machinery Repair Maintenance Supervisor include mechanical and electrical maintenance, troubleshooting, preventive maintenance, predictive maintenance, and root cause analysis.

What are the primary responsibilities of a Machinery Repair Maintenance Supervisor?

The primary responsibilities of a Machinery Repair Maintenance Supervisor include supervising a team of machinery repair technicians, developing and implementing a comprehensive maintenance plan, implementing predictive maintenance techniques, training and mentoring new technicians, collaborating with engineers and production teams to resolve equipmentrelated issues, managing a budget, and utilizing a computerized maintenance management system (CMMS).

What are the career prospects for a Machinery Repair Maintenance Supervisor?

The career prospects for a Machinery Repair Maintenance Supervisor are excellent, as there is a high demand for qualified candidates in this field. With experience and additional training, Machinery Repair Maintenance Supervisors can advance to positions such as Maintenance Manager, Plant Manager, or Operations Manager.

What is the average salary for a Machinery Repair Maintenance Supervisor?

The average salary for a Machinery Repair Maintenance Supervisor in the United States is between $70,000 and $100,000 per year.

What are some tips for writing a standout Machinery Repair Maintenance Supervisor resume?

Some tips for writing a standout Machinery Repair Maintenance Supervisor resume include highlighting your experience in leading and supervising a team of machinery repair technicians, quantifying your accomplishments with specific metrics, showcasing your knowledge of predictive maintenance techniques, emphasizing your ability to collaborate with engineers and production teams to resolve equipmentrelated issues, and demonstrating your commitment to continuous improvement by highlighting your role in implementing a computerized maintenance management system (CMMS) or other initiatives to streamline operations.

What are the common interview questions for a Machinery Repair Maintenance Supervisor position?

Common interview questions for a Machinery Repair Maintenance Supervisor position include questions about your experience in leading and supervising a team of machinery repair technicians, your knowledge of predictive maintenance techniques, your ability to troubleshoot and resolve complex equipment issues, your experience in implementing and managing a computerized maintenance management system (CMMS), and your commitment to safety and quality.

What are the best companies for Machinery Repair Maintenance Supervisors?

Some of the best companies for Machinery Repair Maintenance Supervisors include Schneider Electric, Rockwell Automation, Siemens, GE, and Johnson Controls.

What are the key challenges facing Machinery Repair Maintenance Supervisors?

Some of the key challenges facing Machinery Repair Maintenance Supervisors include the need to keep up with the latest technology, the need to manage a team of technicians, and the need to meet the demands of production.