Are you a seasoned Machining and Assembly Supervisor seeking a new career path? Discover our professionally built Machining and Assembly Supervisor Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

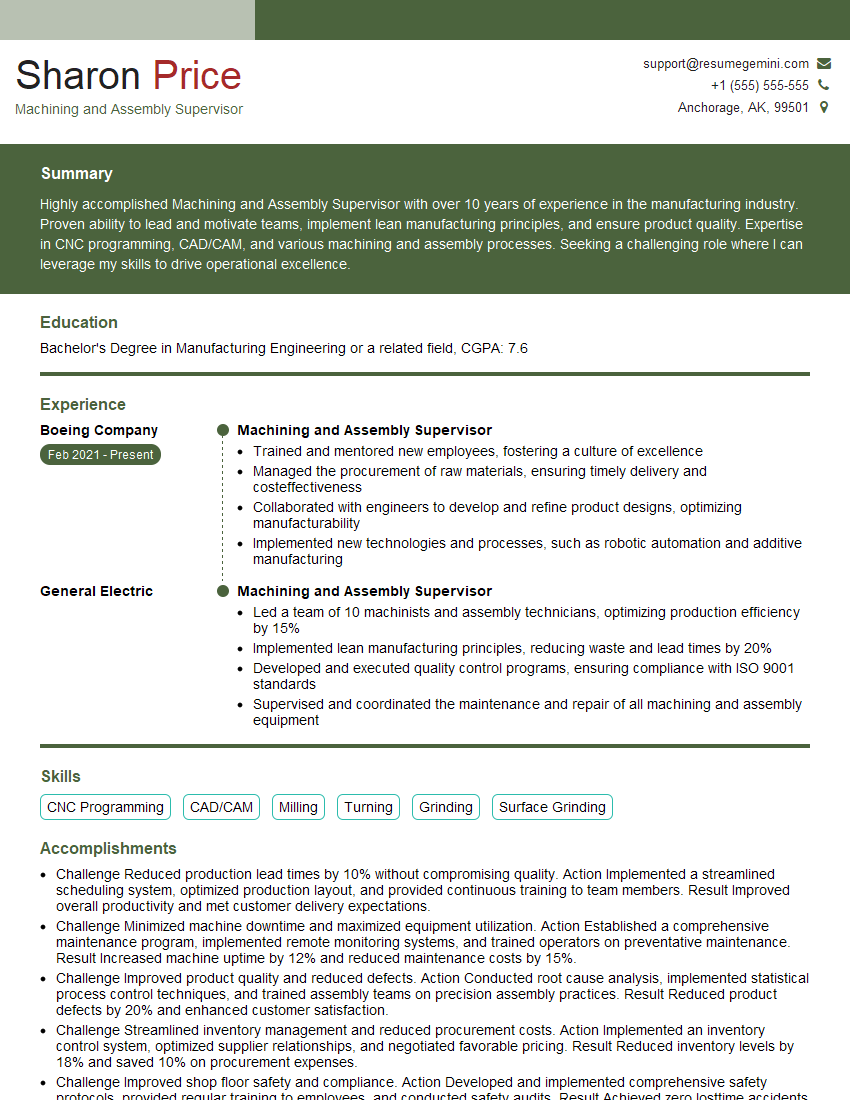

Sharon Price

Machining and Assembly Supervisor

Summary

Highly accomplished Machining and Assembly Supervisor with over 10 years of experience in the manufacturing industry. Proven ability to lead and motivate teams, implement lean manufacturing principles, and ensure product quality. Expertise in CNC programming, CAD/CAM, and various machining and assembly processes. Seeking a challenging role where I can leverage my skills to drive operational excellence.

Education

Bachelor’s Degree in Manufacturing Engineering or a related field

January 2017

Skills

- CNC Programming

- CAD/CAM

- Milling

- Turning

- Grinding

- Surface Grinding

Work Experience

Machining and Assembly Supervisor

- Trained and mentored new employees, fostering a culture of excellence

- Managed the procurement of raw materials, ensuring timely delivery and costeffectiveness

- Collaborated with engineers to develop and refine product designs, optimizing manufacturability

- Implemented new technologies and processes, such as robotic automation and additive manufacturing

Machining and Assembly Supervisor

- Led a team of 10 machinists and assembly technicians, optimizing production efficiency by 15%

- Implemented lean manufacturing principles, reducing waste and lead times by 20%

- Developed and executed quality control programs, ensuring compliance with ISO 9001 standards

- Supervised and coordinated the maintenance and repair of all machining and assembly equipment

Accomplishments

- Challenge Reduced production lead times by 10% without compromising quality. Action Implemented a streamlined scheduling system, optimized production layout, and provided continuous training to team members. Result Improved overall productivity and met customer delivery expectations.

- Challenge Minimized machine downtime and maximized equipment utilization. Action Established a comprehensive maintenance program, implemented remote monitoring systems, and trained operators on preventative maintenance. Result Increased machine uptime by 12% and reduced maintenance costs by 15%.

- Challenge Improved product quality and reduced defects. Action Conducted root cause analysis, implemented statistical process control techniques, and trained assembly teams on precision assembly practices. Result Reduced product defects by 20% and enhanced customer satisfaction.

- Challenge Streamlined inventory management and reduced procurement costs. Action Implemented an inventory control system, optimized supplier relationships, and negotiated favorable pricing. Result Reduced inventory levels by 18% and saved 10% on procurement expenses.

- Challenge Improved shop floor safety and compliance. Action Developed and implemented comprehensive safety protocols, provided regular training to employees, and conducted safety audits. Result Achieved zero losttime accidents for over 500 days.

Awards

- Recognized with the Excellence in Manufacturing Award for consistently exceeding production targets and minimizing scrap.

- Awarded the Innovation Award for developing a new assembly process that improved efficiency by 15%.

- Honored with the Leadership Award for successfully mentoring and developing a team of highly skilled machinists and assembly technicians.

- Recipient of the Operational Excellence Award for implementing lean manufacturing principles and achieving significant improvements in production efficiency.

Certificates

- Certified Machinist

- Certified Assembly Technician

- Certified Six Sigma Green Belt

- Certified Lean Manufacturing Specialist

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Machining and Assembly Supervisor

- Quantify your accomplishments with specific metrics and data whenever possible.

- Highlight your expertise in lean manufacturing principles, such as Six Sigma and Kaizen.

- Showcase your ability to manage and motivate diverse teams effectively.

- Emphasize your knowledge of CNC programming, CAD/CAM, and industry-specific software.

- Proofread your resume carefully for errors and ensure it is well-organized and easy to read.

Essential Experience Highlights for a Strong Machining and Assembly Supervisor Resume

- Managed a team of machinists and assembly technicians, providing guidance and training to optimize production efficiency and ensure adherence to quality standards.

- Developed and implemented lean manufacturing principles to reduce waste, improve lead times, and enhance overall productivity.

- Established and maintained quality control programs to ensure compliance with ISO 9001 standards, minimizing defects and ensuring product consistency.

- Supervised and coordinated the maintenance and repair of all machining and assembly equipment, ensuring optimal performance and minimizing downtime.

- Collaborated with engineers to develop and refine product designs, optimizing manufacturability and ensuring efficient production.

- Managed the procurement of raw materials, evaluating suppliers, negotiating contracts, and ensuring timely delivery to meet production schedules.

Frequently Asked Questions (FAQ’s) For Machining and Assembly Supervisor

What are the key skills required for a Machining and Assembly Supervisor?

Key skills include CNC programming, CAD/CAM, milling, turning, grinding, surface grinding, and a strong understanding of lean manufacturing principles.

What are the typical responsibilities of a Machining and Assembly Supervisor?

Responsibilities include managing teams, implementing lean manufacturing, ensuring quality control, supervising equipment maintenance, and collaborating with engineers.

What are the career advancement opportunities for a Machining and Assembly Supervisor?

With experience and additional qualifications, supervisors can advance to roles such as Production Manager, Manufacturing Engineer, or Plant Manager.

What are the educational requirements for a Machining and Assembly Supervisor?

A bachelor’s degree in Manufacturing Engineering or a related field is typically required, along with relevant industry experience.

What industries employ Machining and Assembly Supervisors?

Supervisors are employed in various industries, including automotive, aerospace, medical, and electronics manufacturing.

What are the key challenges faced by Machining and Assembly Supervisors?

Challenges include managing production schedules, meeting quality standards, controlling costs, and ensuring employee safety.