Are you a seasoned Magnaflux Operator seeking a new career path? Discover our professionally built Magnaflux Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

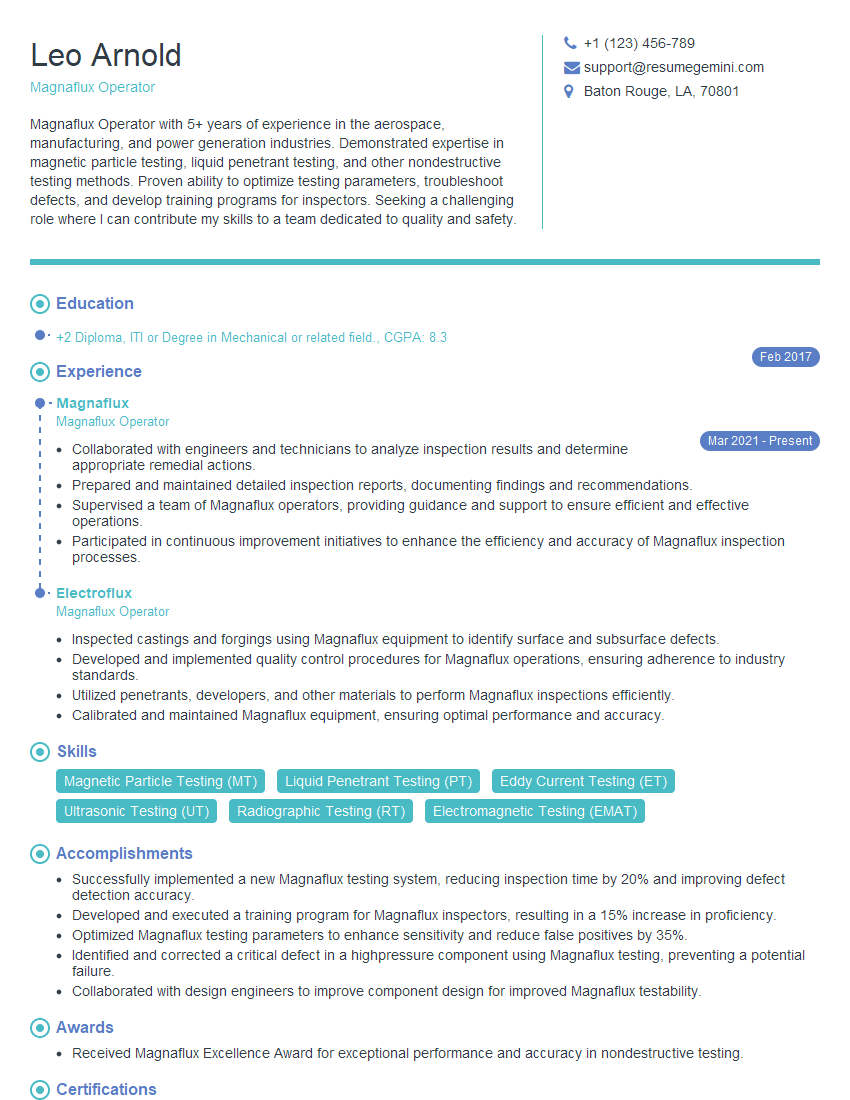

Leo Arnold

Magnaflux Operator

Summary

Magnaflux Operator with 5+ years of experience in the aerospace, manufacturing, and power generation industries. Demonstrated expertise in magnetic particle testing, liquid penetrant testing, and other nondestructive testing methods. Proven ability to optimize testing parameters, troubleshoot defects, and develop training programs for inspectors. Seeking a challenging role where I can contribute my skills to a team dedicated to quality and safety.

Education

+2 Diploma, ITI or Degree in Mechanical or related field.

February 2017

Skills

- Magnetic Particle Testing (MT)

- Liquid Penetrant Testing (PT)

- Eddy Current Testing (ET)

- Ultrasonic Testing (UT)

- Radiographic Testing (RT)

- Electromagnetic Testing (EMAT)

Work Experience

Magnaflux Operator

- Collaborated with engineers and technicians to analyze inspection results and determine appropriate remedial actions.

- Prepared and maintained detailed inspection reports, documenting findings and recommendations.

- Supervised a team of Magnaflux operators, providing guidance and support to ensure efficient and effective operations.

- Participated in continuous improvement initiatives to enhance the efficiency and accuracy of Magnaflux inspection processes.

Magnaflux Operator

- Inspected castings and forgings using Magnaflux equipment to identify surface and subsurface defects.

- Developed and implemented quality control procedures for Magnaflux operations, ensuring adherence to industry standards.

- Utilized penetrants, developers, and other materials to perform Magnaflux inspections efficiently.

- Calibrated and maintained Magnaflux equipment, ensuring optimal performance and accuracy.

Accomplishments

- Successfully implemented a new Magnaflux testing system, reducing inspection time by 20% and improving defect detection accuracy.

- Developed and executed a training program for Magnaflux inspectors, resulting in a 15% increase in proficiency.

- Optimized Magnaflux testing parameters to enhance sensitivity and reduce false positives by 35%.

- Identified and corrected a critical defect in a highpressure component using Magnaflux testing, preventing a potential failure.

- Collaborated with design engineers to improve component design for improved Magnaflux testability.

Awards

- Received Magnaflux Excellence Award for exceptional performance and accuracy in nondestructive testing.

Certificates

- ASNT NDT Level III

- NAS 410 Certification

- API RP 578 Certification

- AWS QC1 Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Magnaflux Operator

- Highlight your experience with specific types of equipment and materials, such as Magnaflux machines, ferrous and non-ferrous alloys, etc.

- Showcase your understanding of industry standards and regulations, such as AWS, ASME, and ISO.

- Emphasize your problem-solving abilities and experience in troubleshooting and resolving testing issues.

- Quantify your accomplishments with specific metrics, such as reducing inspection time and improving defect detection accuracy.

Essential Experience Highlights for a Strong Magnaflux Operator Resume

- Conduct magnetic particle testing (MT) and liquid penetrant testing (PT) to detect surface and subsurface defects in materials.

- Interpret test results and generate reports for documentation and quality control purposes.

- Maintain and calibrate Magnaflux testing equipment to ensure accurate and reliable results.

- Troubleshoot and resolve testing issues, including false positives and low sensitivity.

- Develop and implement training programs for Magnaflux inspectors to enhance their proficiency and skillset.

- Collaborate with quality control department to establish and maintain testing standards and procedures.

- Stay updated with industry best practices and advancements in non-destructive testing techniques.

Frequently Asked Questions (FAQ’s) For Magnaflux Operator

What is Magnaflux testing used for?

Magnaflux testing, more commonly known as magnetic particle testing (MT), is a nondestructive testing (NDT) technique used to detect surface and subsurface defects in ferromagnetic materials, such as iron, steel, and nickel. It involves inducing a magnetic field in the material and applying magnetic particles to the surface. Any defects or discontinuities in the material will cause the particles to accumulate, creating visible indications that can be inspected to determine the extent and severity of the defect.

What qualifications are required to become a Magnaflux Operator?

Typically, a high school diploma or equivalent, with additional training and certification in nondestructive testing, specifically magnetic particle testing (MT). Some employers may require industry-recognized certifications from organizations such as the American Society for Nondestructive Testing (ASNT) or the Canadian Institute for Non-Destructive Evaluation (CINDE).

What are the career prospects for Magnaflux Operators?

Magnaflux Operators are in high demand in various industries, including aerospace, manufacturing, automotive, oil and gas, and power generation. With experience and additional certifications in other NDT methods, such as liquid penetrant testing (PT), ultrasonic testing (UT), and radiographic testing (RT), advancement opportunities exist in quality control, inspection management, and engineering roles.

What is the work environment like for Magnaflux Operators?

Magnaflux Operators typically work in industrial settings, such as manufacturing plants, maintenance facilities, and inspection labs. They may work independently or as part of a team, and often work with other technicians, engineers, and quality control personnel. The work can be physically demanding and requires attention to detail, as well as the ability to work in confined spaces or at heights.

What are the safety precautions that Magnaflux Operators must follow?

Magnaflux Operators should be aware of the potential hazards associated with working with electrical equipment, magnetic fields, and hazardous materials. They must wear appropriate personal protective equipment (PPE), such as gloves, safety glasses, and hearing protection, and follow established safety protocols to minimize the risk of accidents or injuries.

How can I improve my skills as a Magnaflux Operator?

To enhance your skills as a Magnaflux Operator, consider obtaining industry-recognized certifications, such as those offered by ASNT or CINDE. Additionally, seek opportunities to work with experienced operators and participate in training programs or workshops to stay updated with the latest techniques and best practices in the field.

What are the key qualities of a successful Magnaflux Operator?

Successful Magnaflux Operators possess a strong understanding of magnetic particle testing principles and techniques, as well as the ability to interpret test results accurately. They are detail-oriented, with excellent observation skills and the ability to work independently and as part of a team. Good communication and documentation skills are also essential to effectively convey findings and maintain records.

What is the typical salary range for Magnaflux Operators?

The salary range for Magnaflux Operators can vary depending on factors such as experience, location, and industry. According to Salary.com, the average salary for a Magnaflux Operator in the United States is around $55,000 per year.