Are you a seasoned Maintainer Operator seeking a new career path? Discover our professionally built Maintainer Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

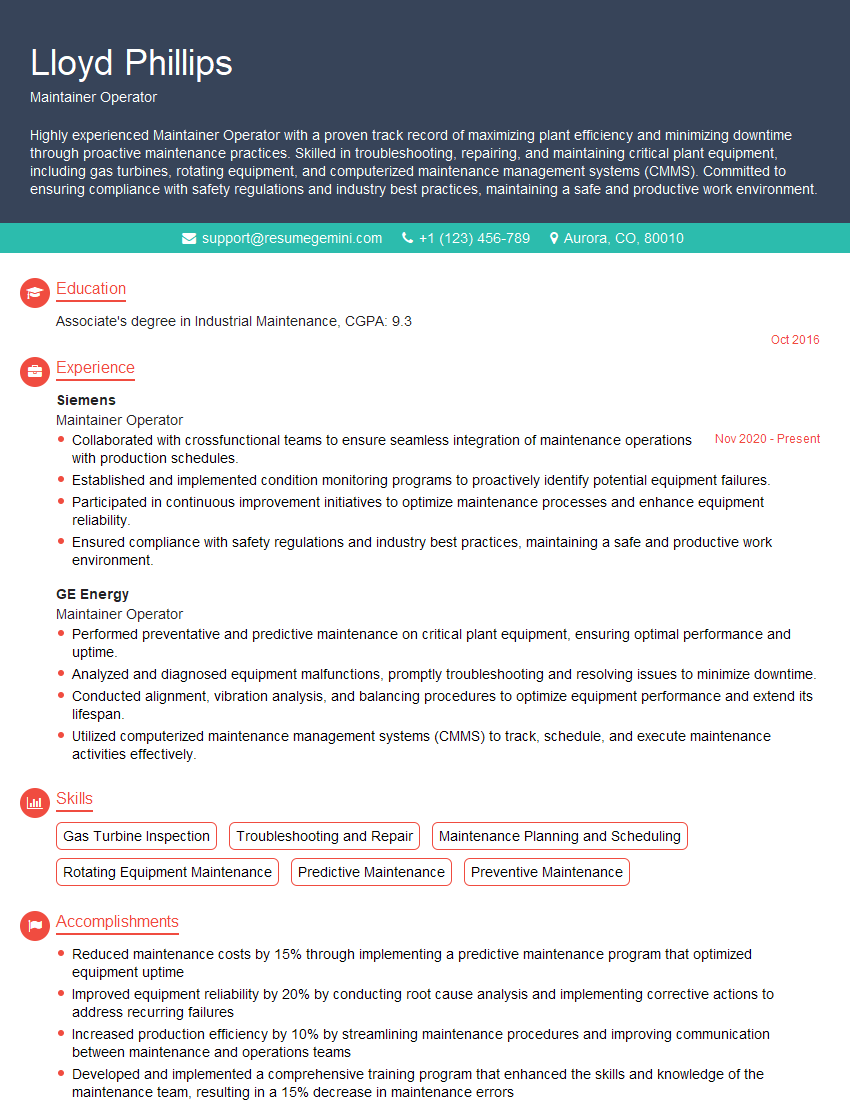

Lloyd Phillips

Maintainer Operator

Summary

Highly experienced Maintainer Operator with a proven track record of maximizing plant efficiency and minimizing downtime through proactive maintenance practices. Skilled in troubleshooting, repairing, and maintaining critical plant equipment, including gas turbines, rotating equipment, and computerized maintenance management systems (CMMS). Committed to ensuring compliance with safety regulations and industry best practices, maintaining a safe and productive work environment.

Education

Associate’s degree in Industrial Maintenance

October 2016

Skills

- Gas Turbine Inspection

- Troubleshooting and Repair

- Maintenance Planning and Scheduling

- Rotating Equipment Maintenance

- Predictive Maintenance

- Preventive Maintenance

Work Experience

Maintainer Operator

- Collaborated with crossfunctional teams to ensure seamless integration of maintenance operations with production schedules.

- Established and implemented condition monitoring programs to proactively identify potential equipment failures.

- Participated in continuous improvement initiatives to optimize maintenance processes and enhance equipment reliability.

- Ensured compliance with safety regulations and industry best practices, maintaining a safe and productive work environment.

Maintainer Operator

- Performed preventative and predictive maintenance on critical plant equipment, ensuring optimal performance and uptime.

- Analyzed and diagnosed equipment malfunctions, promptly troubleshooting and resolving issues to minimize downtime.

- Conducted alignment, vibration analysis, and balancing procedures to optimize equipment performance and extend its lifespan.

- Utilized computerized maintenance management systems (CMMS) to track, schedule, and execute maintenance activities effectively.

Accomplishments

- Reduced maintenance costs by 15% through implementing a predictive maintenance program that optimized equipment uptime

- Improved equipment reliability by 20% by conducting root cause analysis and implementing corrective actions to address recurring failures

- Increased production efficiency by 10% by streamlining maintenance procedures and improving communication between maintenance and operations teams

- Developed and implemented a comprehensive training program that enhanced the skills and knowledge of the maintenance team, resulting in a 15% decrease in maintenance errors

- Utilized advanced diagnostic tools and techniques to identify and resolve complex equipment malfunctions, preventing unplanned downtime

Awards

- Recognized as the Technician of the Year by the Association of Maintenance Professionals for outstanding technical skills and innovation

- Awarded a Certificate of Merit from the International Society of Maintenance and Reliability Professionals for contributing to the advancement of the profession

Certificates

- Certified Maintenance and Reliability Professional (CMRP)

- Certified Maintenance Manager (CMM)

- Certified Maintenance Technician (CMT)

- Certified Predictive Maintenance Technician (CPMT)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Maintainer Operator

- Quantify your accomplishments using specific metrics, such as the percentage of uptime achieved or the reduction in maintenance costs.

- Highlight your expertise in specific maintenance techniques, such as gas turbine inspection, troubleshooting, and repair.

- Showcase your ability to manage multiple projects simultaneously and meet deadlines effectively.

- Emphasize your commitment to safety and compliance with industry regulations.

- Proofread your resume carefully to ensure there are no grammatical or spelling errors.

Essential Experience Highlights for a Strong Maintainer Operator Resume

- Performing preventative and predictive maintenance on critical plant equipment, ensuring optimal performance and uptime.

- Analyzing and diagnosing equipment malfunctions, promptly troubleshooting and resolving issues to minimize downtime.

- Conducting alignment, vibration analysis, and balancing procedures to optimize equipment performance and extend its lifespan.

- Utilizing computerized maintenance management systems (CMMS) to track, schedule, and execute maintenance activities effectively.

- Collaborating with cross-functional teams to ensure seamless integration of maintenance operations with production schedules.

- Establishing and implementing condition monitoring programs to proactively identify potential equipment failures.

Frequently Asked Questions (FAQ’s) For Maintainer Operator

What are the primary responsibilities of a Maintainer Operator?

Maintainer Operators are responsible for maintaining and repairing critical plant equipment to ensure optimal performance and uptime. They perform preventative and predictive maintenance, troubleshoot and resolve equipment malfunctions, and conduct alignment, vibration analysis, and balancing procedures.

What skills are required to become a Maintainer Operator?

Maintainer Operators require a combination of technical skills and knowledge, including gas turbine inspection, troubleshooting and repair, maintenance planning and scheduling, rotating equipment maintenance, predictive maintenance, and preventive maintenance.

What is the job outlook for Maintainer Operators?

The job outlook for Maintainer Operators is expected to be favorable due to the increasing demand for skilled maintenance professionals in various industries.

What industries hire Maintainer Operators?

Maintainer Operators are employed in a wide range of industries, including manufacturing, energy, oil and gas, and transportation.

What is the average salary for a Maintainer Operator?

The average salary for a Maintainer Operator varies depending on experience, location, and industry. According to Salary.com, the average salary for a Maintainer Operator in the United States is around $75,000 per year.