Are you a seasoned Maintenance Equipment Operator seeking a new career path? Discover our professionally built Maintenance Equipment Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

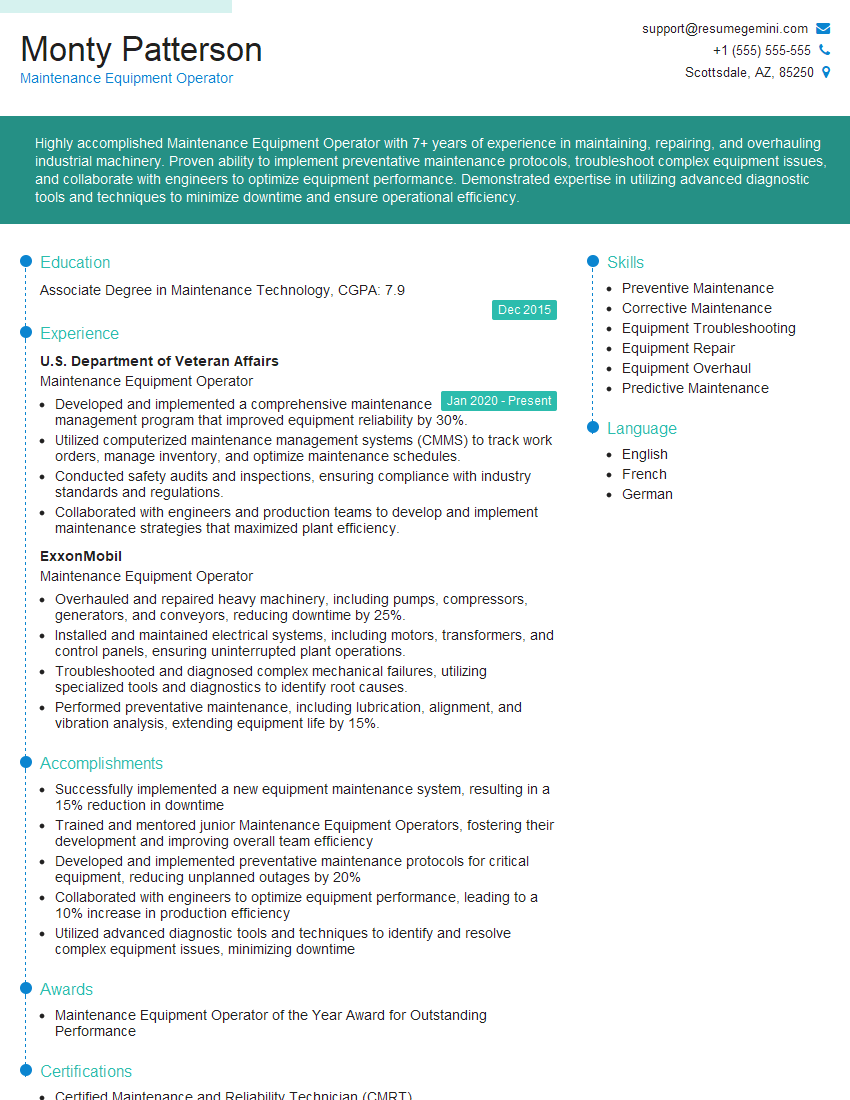

Monty Patterson

Maintenance Equipment Operator

Summary

Highly accomplished Maintenance Equipment Operator with 7+ years of experience in maintaining, repairing, and overhauling industrial machinery. Proven ability to implement preventative maintenance protocols, troubleshoot complex equipment issues, and collaborate with engineers to optimize equipment performance. Demonstrated expertise in utilizing advanced diagnostic tools and techniques to minimize downtime and ensure operational efficiency.

Education

Associate Degree in Maintenance Technology

December 2015

Skills

- Preventive Maintenance

- Corrective Maintenance

- Equipment Troubleshooting

- Equipment Repair

- Equipment Overhaul

- Predictive Maintenance

Work Experience

Maintenance Equipment Operator

- Developed and implemented a comprehensive maintenance management program that improved equipment reliability by 30%.

- Utilized computerized maintenance management systems (CMMS) to track work orders, manage inventory, and optimize maintenance schedules.

- Conducted safety audits and inspections, ensuring compliance with industry standards and regulations.

- Collaborated with engineers and production teams to develop and implement maintenance strategies that maximized plant efficiency.

Maintenance Equipment Operator

- Overhauled and repaired heavy machinery, including pumps, compressors, generators, and conveyors, reducing downtime by 25%.

- Installed and maintained electrical systems, including motors, transformers, and control panels, ensuring uninterrupted plant operations.

- Troubleshooted and diagnosed complex mechanical failures, utilizing specialized tools and diagnostics to identify root causes.

- Performed preventative maintenance, including lubrication, alignment, and vibration analysis, extending equipment life by 15%.

Accomplishments

- Successfully implemented a new equipment maintenance system, resulting in a 15% reduction in downtime

- Trained and mentored junior Maintenance Equipment Operators, fostering their development and improving overall team efficiency

- Developed and implemented preventative maintenance protocols for critical equipment, reducing unplanned outages by 20%

- Collaborated with engineers to optimize equipment performance, leading to a 10% increase in production efficiency

- Utilized advanced diagnostic tools and techniques to identify and resolve complex equipment issues, minimizing downtime

Awards

- Maintenance Equipment Operator of the Year Award for Outstanding Performance

Certificates

- Certified Maintenance and Reliability Technician (CMRT)

- Certified Maintenance Manager (CMM)

- Certified Predictive Maintenance Technician (CPMT)

- Certified Vibration Analyst (CAT I)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Maintenance Equipment Operator

- Quantify your accomplishments with specific metrics whenever possible.

- Highlight your skills in troubleshooting and repairing complex equipment.

- Emphasize your ability to work independently and as part of a team.

- Include keywords relevant to the maintenance equipment operator industry.

- Proofread your resume carefully for any errors.

Essential Experience Highlights for a Strong Maintenance Equipment Operator Resume

- Conduct routine inspections and maintenance on equipment to prevent breakdowns and ensure optimal performance.

- Identify and resolve equipment malfunctions quickly and efficiently, minimizing downtime and production losses.

- Implement and maintain preventative maintenance plans to extend equipment lifespan and reduce the risk of unexpected failures.

- Overhaul and repair major equipment components, including engines, transmissions, and electrical systems.

- Collaborate with engineers and other maintenance personnel to improve equipment performance and reliability.

- Maintain detailed maintenance records and document all work performed for auditing and compliance purposes.

- Stay up-to-date on industry best practices and technological advancements in maintenance equipment operation.

Frequently Asked Questions (FAQ’s) For Maintenance Equipment Operator

What are the key skills required to be a successful Maintenance Equipment Operator?

The key skills required to be a successful Maintenance Equipment Operator include preventative maintenance, corrective maintenance, equipment troubleshooting, equipment repair, equipment overhaul, and predictive maintenance.

What are the common responsibilities of a Maintenance Equipment Operator?

Common responsibilities of a Maintenance Equipment Operator include conducting routine inspections and maintenance, identifying and resolving equipment malfunctions, implementing and maintaining preventative maintenance plans, overhauling and repairing major equipment components, and collaborating with engineers to improve equipment performance.

What are the career prospects for a Maintenance Equipment Operator?

Maintenance Equipment Operators can advance their careers by becoming Maintenance Supervisors, Maintenance Managers, or Plant Engineers. With additional training and experience, they can also specialize in specific areas of maintenance, such as electrical or mechanical maintenance.

What are the typical working conditions for a Maintenance Equipment Operator?

Maintenance Equipment Operators typically work in industrial settings, such as factories, power plants, and construction sites. They may work indoors or outdoors, and may be exposed to noise, dust, and other hazards.

What is the average salary for a Maintenance Equipment Operator?

The average salary for a Maintenance Equipment Operator varies depending on factors such as experience, location, and industry. According to the U.S. Bureau of Labor Statistics, the median annual salary for Maintenance and Repair Workers in 2021 was $46,210.

What are the educational requirements for a Maintenance Equipment Operator?

Most Maintenance Equipment Operators have a high school diploma or equivalent. Some employers may prefer candidates with an Associate Degree in Maintenance Technology or a related field.