Are you a seasoned Maintenance Welder seeking a new career path? Discover our professionally built Maintenance Welder Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

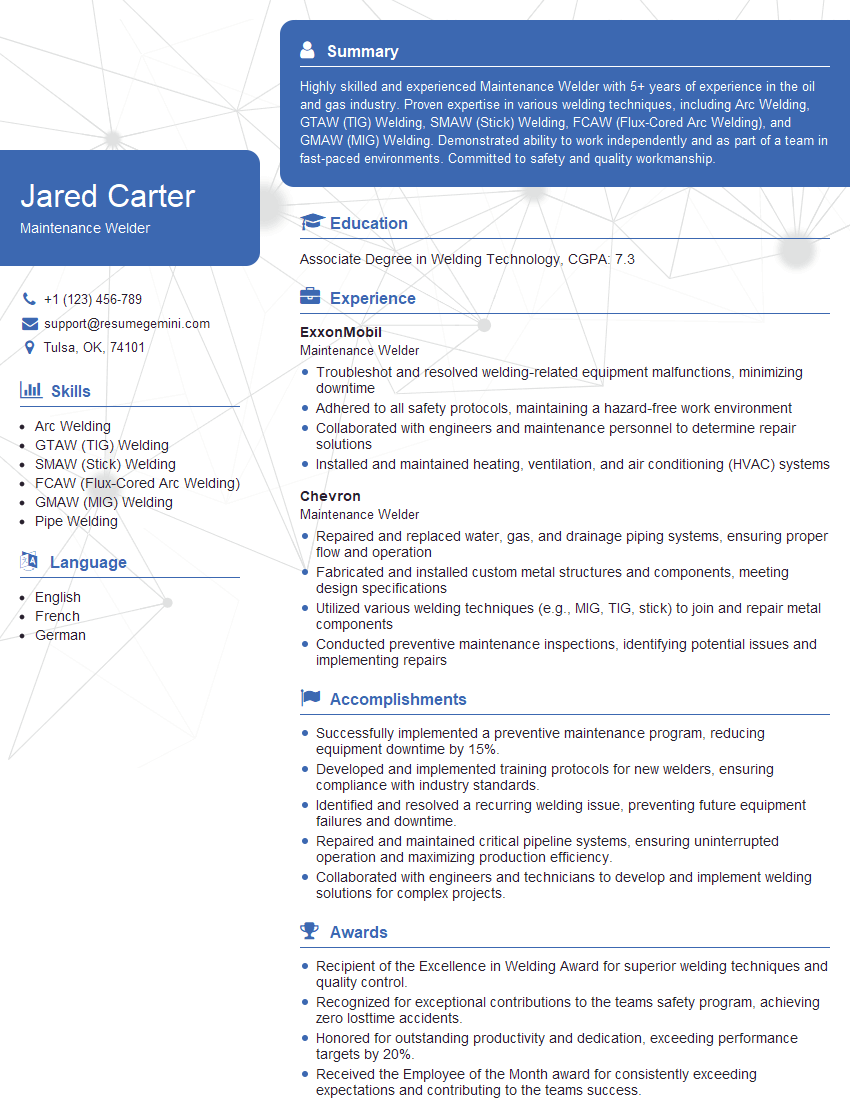

Jared Carter

Maintenance Welder

Summary

Highly skilled and experienced Maintenance Welder with 5+ years of experience in the oil and gas industry. Proven expertise in various welding techniques, including Arc Welding, GTAW (TIG) Welding, SMAW (Stick) Welding, FCAW (Flux-Cored Arc Welding), and GMAW (MIG) Welding. Demonstrated ability to work independently and as part of a team in fast-paced environments. Committed to safety and quality workmanship.

Education

Associate Degree in Welding Technology

April 2019

Skills

- Arc Welding

- GTAW (TIG) Welding

- SMAW (Stick) Welding

- FCAW (Flux-Cored Arc Welding)

- GMAW (MIG) Welding

- Pipe Welding

Work Experience

Maintenance Welder

- Troubleshot and resolved welding-related equipment malfunctions, minimizing downtime

- Adhered to all safety protocols, maintaining a hazard-free work environment

- Collaborated with engineers and maintenance personnel to determine repair solutions

- Installed and maintained heating, ventilation, and air conditioning (HVAC) systems

Maintenance Welder

- Repaired and replaced water, gas, and drainage piping systems, ensuring proper flow and operation

- Fabricated and installed custom metal structures and components, meeting design specifications

- Utilized various welding techniques (e.g., MIG, TIG, stick) to join and repair metal components

- Conducted preventive maintenance inspections, identifying potential issues and implementing repairs

Accomplishments

- Successfully implemented a preventive maintenance program, reducing equipment downtime by 15%.

- Developed and implemented training protocols for new welders, ensuring compliance with industry standards.

- Identified and resolved a recurring welding issue, preventing future equipment failures and downtime.

- Repaired and maintained critical pipeline systems, ensuring uninterrupted operation and maximizing production efficiency.

- Collaborated with engineers and technicians to develop and implement welding solutions for complex projects.

Awards

- Recipient of the Excellence in Welding Award for superior welding techniques and quality control.

- Recognized for exceptional contributions to the teams safety program, achieving zero losttime accidents.

- Honored for outstanding productivity and dedication, exceeding performance targets by 20%.

- Received the Employee of the Month award for consistently exceeding expectations and contributing to the teams success.

Certificates

- AWS Certified Welder

- ASME Boiler and Pressure Vessel Code Inspector

- National Institute for Certification in Engineering Technologies (NICET)

- Industrial Maintenance Journeyman Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Maintenance Welder

- Highlight your experience with specific welding techniques and equipment.

- Quantify your accomplishments whenever possible using specific metrics.

- Tailor your resume to each specific job you are applying for.

- Proofread your resume carefully for any errors.

- Get feedback from a career counselor or resume writer if possible.

Essential Experience Highlights for a Strong Maintenance Welder Resume

- Perform various welding tasks, including repairs, modifications, and installations on pipelines, pressure vessels, and other equipment

- Read and interpret blueprints and specifications to ensure accurate welding

- Conduct inspections and tests to ensure the quality and safety of welds

- Troubleshoot and resolve welding problems

- Maintain welding equipment and supplies

- Follow all safety regulations and procedures

Frequently Asked Questions (FAQ’s) For Maintenance Welder

What is the job outlook for Maintenance Welders?

The job outlook for Maintenance Welders is expected to be good over the next few years. As industries continue to grow and expand, there will be a need for qualified welders to maintain and repair equipment and structures.

What are the educational requirements for Maintenance Welders?

Most Maintenance Welders have at least a high school diploma or equivalent. Some employers may prefer candidates with an associate degree in welding technology or a related field.

What are the key skills for Maintenance Welders?

The key skills for Maintenance Welders include proficiency in various welding techniques, the ability to read and interpret blueprints and specifications, and the ability to troubleshoot and resolve welding problems.

What are the typical working conditions for Maintenance Welders?

Maintenance Welders typically work in industrial settings, such as factories, power plants, and refineries. They may work outdoors in all types of weather conditions.

What is the average salary for Maintenance Welders?

The average salary for Maintenance Welders is around $45,000 per year. However, salaries can vary depending on experience, location, and industry.

What are the career advancement opportunities for Maintenance Welders?

Maintenance Welders can advance their careers by becoming certified in specific welding techniques, gaining experience in different industries, and taking on supervisory roles.