Are you a seasoned Major Appliance Assembly Supervisor seeking a new career path? Discover our professionally built Major Appliance Assembly Supervisor Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

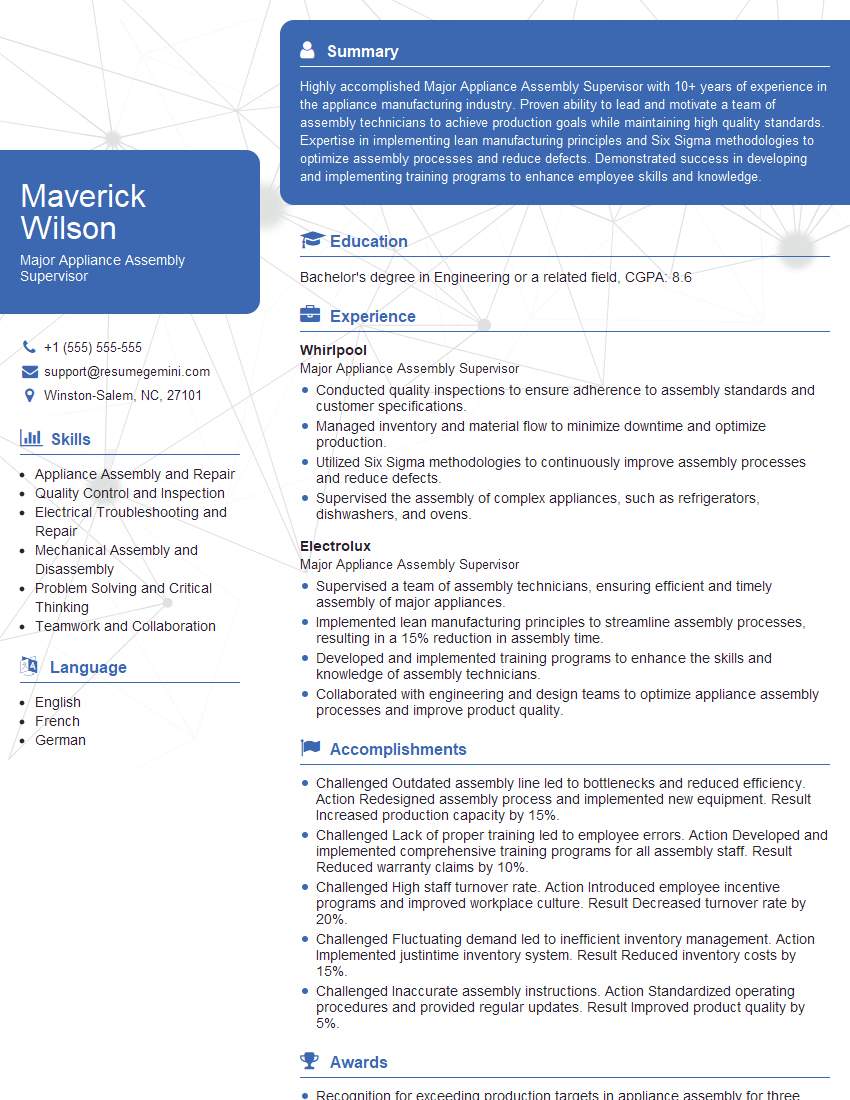

Maverick Wilson

Major Appliance Assembly Supervisor

Summary

Highly accomplished Major Appliance Assembly Supervisor with 10+ years of experience in the appliance manufacturing industry. Proven ability to lead and motivate a team of assembly technicians to achieve production goals while maintaining high quality standards. Expertise in implementing lean manufacturing principles and Six Sigma methodologies to optimize assembly processes and reduce defects. Demonstrated success in developing and implementing training programs to enhance employee skills and knowledge.

Education

Bachelor’s degree in Engineering or a related field

August 2015

Skills

- Appliance Assembly and Repair

- Quality Control and Inspection

- Electrical Troubleshooting and Repair

- Mechanical Assembly and Disassembly

- Problem Solving and Critical Thinking

- Teamwork and Collaboration

Work Experience

Major Appliance Assembly Supervisor

- Conducted quality inspections to ensure adherence to assembly standards and customer specifications.

- Managed inventory and material flow to minimize downtime and optimize production.

- Utilized Six Sigma methodologies to continuously improve assembly processes and reduce defects.

- Supervised the assembly of complex appliances, such as refrigerators, dishwashers, and ovens.

Major Appliance Assembly Supervisor

- Supervised a team of assembly technicians, ensuring efficient and timely assembly of major appliances.

- Implemented lean manufacturing principles to streamline assembly processes, resulting in a 15% reduction in assembly time.

- Developed and implemented training programs to enhance the skills and knowledge of assembly technicians.

- Collaborated with engineering and design teams to optimize appliance assembly processes and improve product quality.

Accomplishments

- Challenged Outdated assembly line led to bottlenecks and reduced efficiency. Action Redesigned assembly process and implemented new equipment. Result Increased production capacity by 15%.

- Challenged Lack of proper training led to employee errors. Action Developed and implemented comprehensive training programs for all assembly staff. Result Reduced warranty claims by 10%.

- Challenged High staff turnover rate. Action Introduced employee incentive programs and improved workplace culture. Result Decreased turnover rate by 20%.

- Challenged Fluctuating demand led to inefficient inventory management. Action Implemented justintime inventory system. Result Reduced inventory costs by 15%.

- Challenged Inaccurate assembly instructions. Action Standardized operating procedures and provided regular updates. Result Improved product quality by 5%.

Awards

- Recognition for exceeding production targets in appliance assembly for three consecutive quarters.

- Award for implementing quality control measures that reduced assembly defects by 25%.

- Award for developing innovative assembly techniques that reduced cycle time by 10%.

- Recognition for maintaining a safe and efficient work environment for all employees.

Certificates

- Certified Appliance Professional (CAP)

- Certified Major Appliance Installer

- OSHA 30-Hour Safety Training

- National Appliance Service Technician Certification (NASTeC)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Major Appliance Assembly Supervisor

- Highlight your experience in supervising a team of assembly technicians and your ability to implement lean manufacturing principles.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate the impact of your work.

- Tailor your resume to each job you apply for, highlighting the skills and experience that are most relevant to the position.

- Proofread your resume carefully before submitting it to ensure that it is error-free.

Essential Experience Highlights for a Strong Major Appliance Assembly Supervisor Resume

- Supervise a team of assembly technicians to ensure efficient and timely assembly of major appliances.

- Implement lean manufacturing principles to streamline assembly processes and reduce assembly time.

- Develop and implement training programs to enhance the skills and knowledge of assembly technicians.

- Collaborate with engineering and design teams to optimize appliance assembly processes and improve product quality.

- Conduct quality inspections to ensure adherence to assembly standards and customer specifications.

- Manage inventory and material flow to minimize downtime and optimize production.

Frequently Asked Questions (FAQ’s) For Major Appliance Assembly Supervisor

What is the role of a Major Appliance Assembly Supervisor?

A Major Appliance Assembly Supervisor is responsible for overseeing the assembly of major appliances, such as refrigerators, dishwashers, and ovens. They supervise a team of assembly technicians and ensure that appliances are assembled efficiently and according to quality standards.

What are the qualifications for a Major Appliance Assembly Supervisor?

Most Major Appliance Assembly Supervisors have a bachelor’s degree in engineering or a related field. They also have several years of experience in the appliance manufacturing industry, and they are familiar with lean manufacturing principles and Six Sigma methodologies.

What are the key responsibilities of a Major Appliance Assembly Supervisor?

The key responsibilities of a Major Appliance Assembly Supervisor include supervising a team of assembly technicians, implementing lean manufacturing principles, developing and implementing training programs, collaborating with engineering and design teams, conducting quality inspections, and managing inventory and material flow.

What are the challenges of being a Major Appliance Assembly Supervisor?

The challenges of being a Major Appliance Assembly Supervisor include managing a team of employees, meeting production goals, and ensuring that appliances are assembled according to quality standards. Assembly Supervisors must also be able to adapt to changes in the workplace, such as new technologies and processes.

What are the rewards of being a Major Appliance Assembly Supervisor?

The rewards of being a Major Appliance Assembly Supervisor include the opportunity to lead a team of employees, make a difference in the manufacturing process, and see the products that you help to create being used by consumers.