Are you a seasoned Major Assembly Inspector seeking a new career path? Discover our professionally built Major Assembly Inspector Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

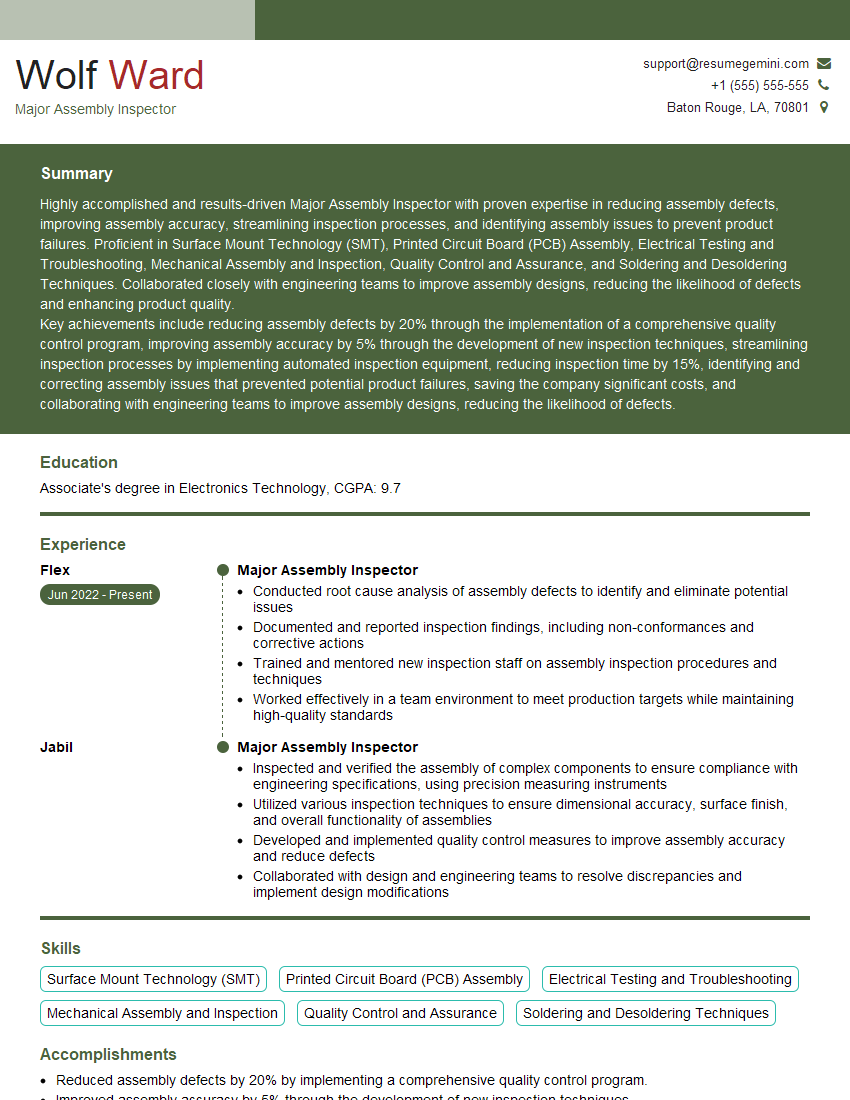

Wolf Ward

Major Assembly Inspector

Summary

Highly accomplished and results-driven Major Assembly Inspector with proven expertise in reducing assembly defects, improving assembly accuracy, streamlining inspection processes, and identifying assembly issues to prevent product failures. Proficient in Surface Mount Technology (SMT), Printed Circuit Board (PCB) Assembly, Electrical Testing and Troubleshooting, Mechanical Assembly and Inspection, Quality Control and Assurance, and Soldering and Desoldering Techniques. Collaborated closely with engineering teams to improve assembly designs, reducing the likelihood of defects and enhancing product quality.

Key achievements include reducing assembly defects by 20% through the implementation of a comprehensive quality control program, improving assembly accuracy by 5% through the development of new inspection techniques, streamlining inspection processes by implementing automated inspection equipment, reducing inspection time by 15%, identifying and correcting assembly issues that prevented potential product failures, saving the company significant costs, and collaborating with engineering teams to improve assembly designs, reducing the likelihood of defects.

Education

Associate’s degree in Electronics Technology

May 2018

Skills

- Surface Mount Technology (SMT)

- Printed Circuit Board (PCB) Assembly

- Electrical Testing and Troubleshooting

- Mechanical Assembly and Inspection

- Quality Control and Assurance

- Soldering and Desoldering Techniques

Work Experience

Major Assembly Inspector

- Conducted root cause analysis of assembly defects to identify and eliminate potential issues

- Documented and reported inspection findings, including non-conformances and corrective actions

- Trained and mentored new inspection staff on assembly inspection procedures and techniques

- Worked effectively in a team environment to meet production targets while maintaining high-quality standards

Major Assembly Inspector

- Inspected and verified the assembly of complex components to ensure compliance with engineering specifications, using precision measuring instruments

- Utilized various inspection techniques to ensure dimensional accuracy, surface finish, and overall functionality of assemblies

- Developed and implemented quality control measures to improve assembly accuracy and reduce defects

- Collaborated with design and engineering teams to resolve discrepancies and implement design modifications

Accomplishments

- Reduced assembly defects by 20% by implementing a comprehensive quality control program.

- Improved assembly accuracy by 5% through the development of new inspection techniques.

- Streamlined inspection processes by implementing automated inspection equipment, reducing inspection time by 15%.

- Identified and corrected assembly issues that prevented potential product failures, saving the company significant costs.

- Collaborated with engineering team to improve assembly designs, reducing the likelihood of defects.

Awards

- Received the Inspector of the Year award for exceptional performance in assembly inspection.

- Recognized for achieving a zeroerror rate in major assembly inspection for consecutive quarters.

- Awarded the Excellence in Quality award for consistently meeting or exceeding quality standards.

- Received the Employee of the Month award for exceptional contributions to the assembly inspection team.

Certificates

- Certified IPC Specialist (CIS)

- Certified IPC Inspector (CII)

- Certified Electronic Assembly Inspector (CEAI)

- Certified Quality Inspector (CQI)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Major Assembly Inspector

Highlight your technical skills:

In your resume, clearly showcase your proficiency in Surface Mount Technology (SMT), Printed Circuit Board (PCB) Assembly, Electrical Testing and Troubleshooting, Mechanical Assembly and Inspection, Quality Control and Assurance, and Soldering and Desoldering Techniques.

Quantify your accomplishments:

Use specific metrics and data to demonstrate the impact of your contributions. For example, you could highlight that you reduced assembly defects by 20% or improved assembly accuracy by 5%. This will provide concrete evidence of your value to potential employers.

Demonstrate your problem-solving abilities:

Provide examples of how you identified and resolved assembly issues that prevented potential product failures. This will showcase your analytical thinking skills and ability to work effectively under pressure.

Emphasize your attention to detail:

As a Major Assembly Inspector, attention to detail is crucial. Highlight your ability to conduct thorough inspections and identify even the smallest defects. Mention any experience you have with using precision measuring instruments or automated inspection systems.

Essential Experience Highlights for a Strong Major Assembly Inspector Resume

- Conduct visual and functional inspections of major assemblies to ensure compliance with specifications and quality standards.

- Utilize various inspection techniques and equipment, including optical comparators, coordinate measuring machines, and automated inspection systems.

- Identify and document defects and non-conformances, and initiate corrective actions to prevent recurrence.

- Interpret blueprints, schematics, and other technical documentation to verify assembly accuracy.

- Participate in quality improvement initiatives and provide feedback to engineering and manufacturing teams to enhance product quality.

- Maintain a clean and organized work area, and adhere to all safety protocols.

- Collaborate with other quality control personnel and production staff to ensure effective quality control measures.

Frequently Asked Questions (FAQ’s) For Major Assembly Inspector

What are the key skills and qualifications required to be a successful Major Assembly Inspector?

To be a successful Major Assembly Inspector, you should have a strong understanding of Surface Mount Technology (SMT), Printed Circuit Board (PCB) Assembly, Electrical Testing and Troubleshooting, Mechanical Assembly and Inspection, Quality Control and Assurance, and Soldering and Desoldering Techniques. You should also possess excellent attention to detail, problem-solving skills, and the ability to work effectively in a fast-paced environment.

What are the typical responsibilities of a Major Assembly Inspector?

Major Assembly Inspectors are responsible for conducting visual and functional inspections of major assemblies to ensure compliance with specifications and quality standards. They identify and document defects and non-conformances, and initiate corrective actions to prevent recurrence. They also interpret blueprints, schematics, and other technical documentation to verify assembly accuracy, and participate in quality improvement initiatives.

What are the career prospects for Major Assembly Inspectors?

Major Assembly Inspectors can advance to roles such as Quality Control Manager, Manufacturing Engineer, or Production Supervisor. With additional education and experience, they may also move into management positions in the quality assurance or manufacturing industry.

What is the job outlook for Major Assembly Inspectors?

The job outlook for Major Assembly Inspectors is expected to be favorable in the coming years due to the increasing demand for electronic products and the need for quality control in the manufacturing industry.

What are the salary expectations for Major Assembly Inspectors?

The salary expectations for Major Assembly Inspectors vary depending on experience, location, and company size. According to Indeed, the average salary for a Major Assembly Inspector in the United States is around $60,000 per year.

What are the top companies that hire Major Assembly Inspectors?

Some of the top companies that hire Major Assembly Inspectors include Flex, Jabil, and Sanmina.

What are the educational requirements to become a Major Assembly Inspector?

Most Major Assembly Inspectors have at least an associate’s degree in Electronics Technology or a related field. Some employers may also require candidates to have experience in the manufacturing industry or in a quality control role.

What are some tips for writing a standout Major Assembly Inspector resume?

To write a standout Major Assembly Inspector resume, highlight your technical skills, quantify your accomplishments, demonstrate your problem-solving abilities, and emphasize your attention to detail.