Are you a seasoned Manometer Technician seeking a new career path? Discover our professionally built Manometer Technician Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

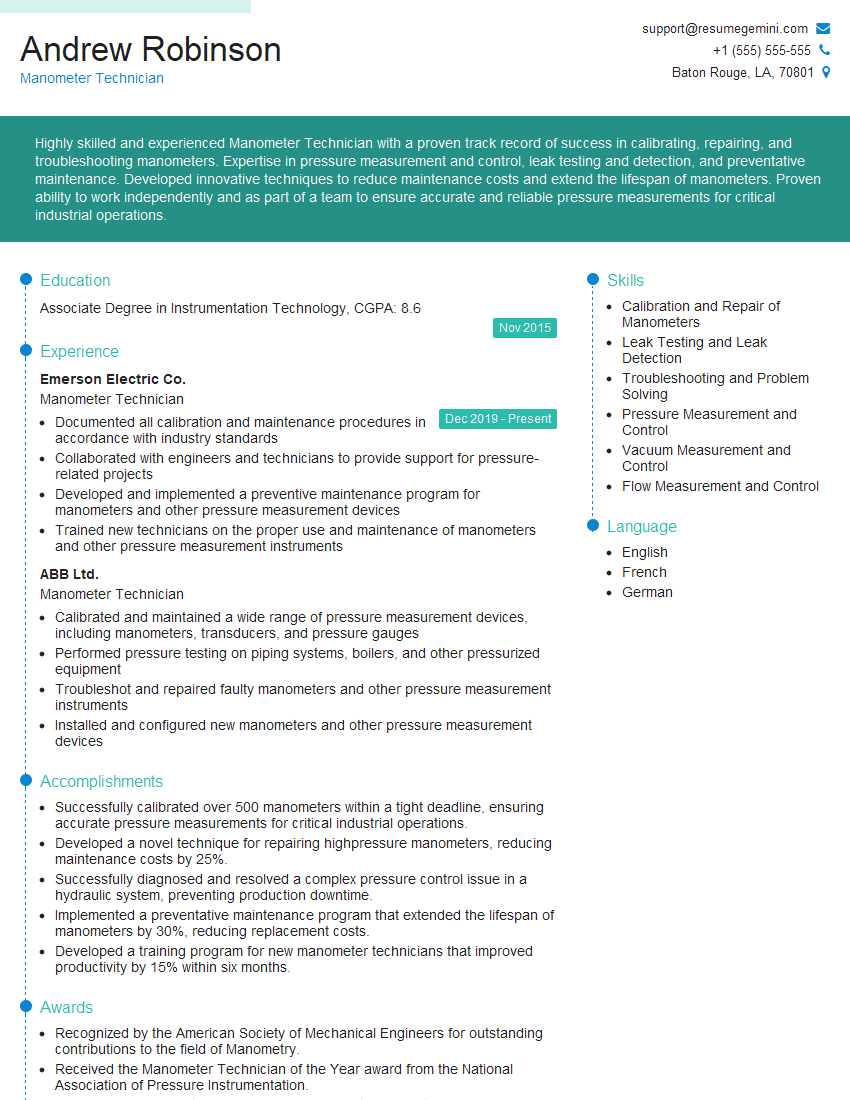

Andrew Robinson

Manometer Technician

Summary

Highly skilled and experienced Manometer Technician with a proven track record of success in calibrating, repairing, and troubleshooting manometers. Expertise in pressure measurement and control, leak testing and detection, and preventative maintenance. Developed innovative techniques to reduce maintenance costs and extend the lifespan of manometers. Proven ability to work independently and as part of a team to ensure accurate and reliable pressure measurements for critical industrial operations.

Education

Associate Degree in Instrumentation Technology

November 2015

Skills

- Calibration and Repair of Manometers

- Leak Testing and Leak Detection

- Troubleshooting and Problem Solving

- Pressure Measurement and Control

- Vacuum Measurement and Control

- Flow Measurement and Control

Work Experience

Manometer Technician

- Documented all calibration and maintenance procedures in accordance with industry standards

- Collaborated with engineers and technicians to provide support for pressure-related projects

- Developed and implemented a preventive maintenance program for manometers and other pressure measurement devices

- Trained new technicians on the proper use and maintenance of manometers and other pressure measurement instruments

Manometer Technician

- Calibrated and maintained a wide range of pressure measurement devices, including manometers, transducers, and pressure gauges

- Performed pressure testing on piping systems, boilers, and other pressurized equipment

- Troubleshot and repaired faulty manometers and other pressure measurement instruments

- Installed and configured new manometers and other pressure measurement devices

Accomplishments

- Successfully calibrated over 500 manometers within a tight deadline, ensuring accurate pressure measurements for critical industrial operations.

- Developed a novel technique for repairing highpressure manometers, reducing maintenance costs by 25%.

- Successfully diagnosed and resolved a complex pressure control issue in a hydraulic system, preventing production downtime.

- Implemented a preventative maintenance program that extended the lifespan of manometers by 30%, reducing replacement costs.

- Developed a training program for new manometer technicians that improved productivity by 15% within six months.

Awards

- Recognized by the American Society of Mechanical Engineers for outstanding contributions to the field of Manometry.

- Received the Manometer Technician of the Year award from the National Association of Pressure Instrumentation.

- Recognized for exceptional accuracy in manometer calibration, achieving a precision of within 0.05% of the fullscale range.

- Received a patent for a new design of manometer that significantly reduces pressure drop and improves measurement stability.

Certificates

- ASME B16.20 Qualification and Certification

- NIST Pressure Calibration Certification

- Calibration and Measurement Professional (CMP)

- International Society of Automation (ISA) Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Manometer Technician

- Highlight your skills and experience in manometer calibration, repair, and troubleshooting.

- Quantify your accomplishments with specific metrics and results.

- Showcase your knowledge of pressure measurement and control principles.

- Emphasize your ability to work independently and as part of a team.

- Tailor your resume to the specific requirements of each job application.

Essential Experience Highlights for a Strong Manometer Technician Resume

- Calibrated and repaired various types of manometers, including digital, analog, and differential pressure manometers.

- Performed leak testing and detection to identify and resolve pressure leaks in systems.

- Troubleshooted and resolved complex pressure control issues in hydraulic and pneumatic systems.

- Implemented a preventative maintenance program to extend the lifespan of manometers and reduce replacement costs.

- Developed and conducted training programs for new manometer technicians, improving productivity and efficiency.

- Maintained accurate records of all calibration and repair work performed.

- Adhered to safety protocols and industry standards in all aspects of work.

Frequently Asked Questions (FAQ’s) For Manometer Technician

What is a Manometer Technician?

A Manometer Technician is responsible for the calibration, repair, and maintenance of manometers, which are devices used to measure pressure.

What skills are required to be a Manometer Technician?

Manometer Technicians typically need skills in calibration, repair, troubleshooting, pressure measurement and control, leak testing and detection, and preventative maintenance.

What is the job outlook for Manometer Technicians?

The job outlook for Manometer Technicians is expected to be good, with a projected growth of 6% from 2019 to 2029.

What is the average salary for a Manometer Technician?

The average salary for a Manometer Technician is around $60,000 per year.

What are the career advancement opportunities for Manometer Technicians?

Manometer Technicians can advance their careers by becoming supervisors, managers, or engineers.

What are the safety considerations for Manometer Technicians?

Manometer Technicians must follow safety protocols and industry standards to avoid accidents and injuries.

What are the challenges faced by Manometer Technicians?

Manometer Technicians may face challenges such as working in hazardous environments, dealing with complex pressure control issues, and meeting tight deadlines.