Are you a seasoned Manual Equipment Mechanic seeking a new career path? Discover our professionally built Manual Equipment Mechanic Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

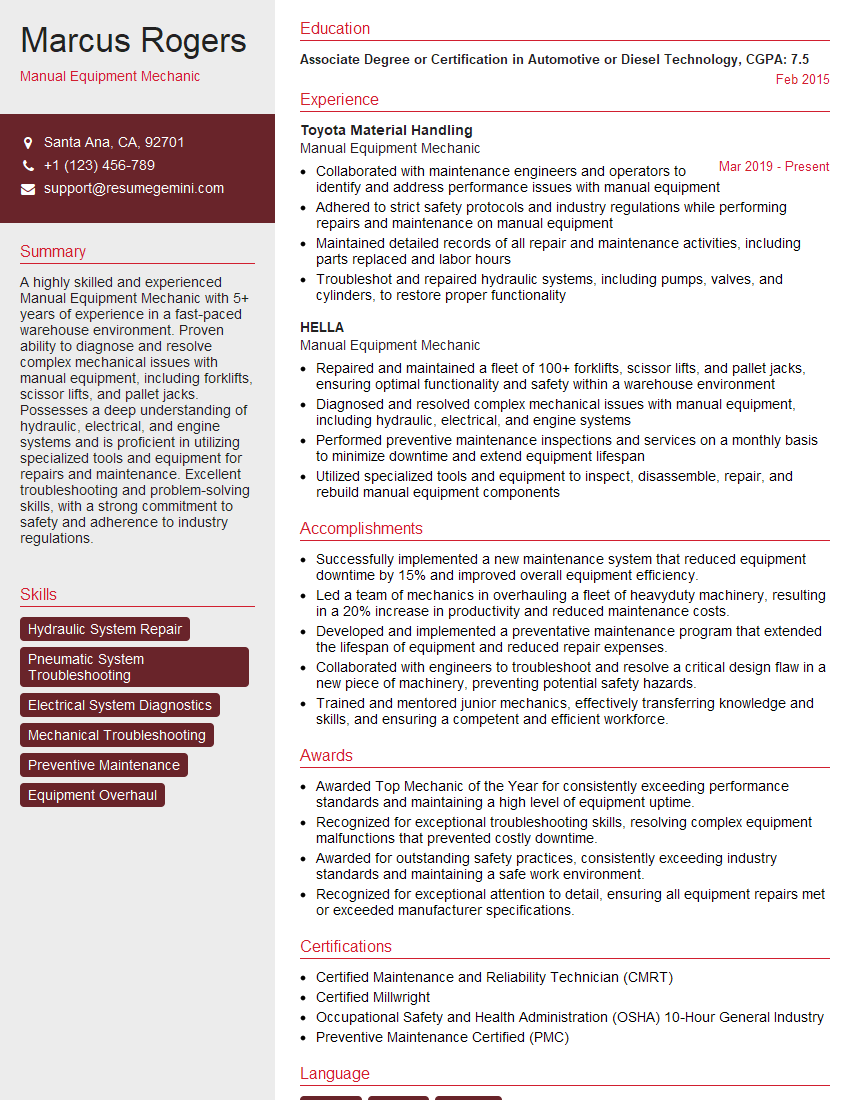

Marcus Rogers

Manual Equipment Mechanic

Summary

A highly skilled and experienced Manual Equipment Mechanic with 5+ years of experience in a fast-paced warehouse environment. Proven ability to diagnose and resolve complex mechanical issues with manual equipment, including forklifts, scissor lifts, and pallet jacks. Possesses a deep understanding of hydraulic, electrical, and engine systems and is proficient in utilizing specialized tools and equipment for repairs and maintenance. Excellent troubleshooting and problem-solving skills, with a strong commitment to safety and adherence to industry regulations.

Education

Associate Degree or Certification in Automotive or Diesel Technology

February 2015

Skills

- Hydraulic System Repair

- Pneumatic System Troubleshooting

- Electrical System Diagnostics

- Mechanical Troubleshooting

- Preventive Maintenance

- Equipment Overhaul

Work Experience

Manual Equipment Mechanic

- Collaborated with maintenance engineers and operators to identify and address performance issues with manual equipment

- Adhered to strict safety protocols and industry regulations while performing repairs and maintenance on manual equipment

- Maintained detailed records of all repair and maintenance activities, including parts replaced and labor hours

- Troubleshot and repaired hydraulic systems, including pumps, valves, and cylinders, to restore proper functionality

Manual Equipment Mechanic

- Repaired and maintained a fleet of 100+ forklifts, scissor lifts, and pallet jacks, ensuring optimal functionality and safety within a warehouse environment

- Diagnosed and resolved complex mechanical issues with manual equipment, including hydraulic, electrical, and engine systems

- Performed preventive maintenance inspections and services on a monthly basis to minimize downtime and extend equipment lifespan

- Utilized specialized tools and equipment to inspect, disassemble, repair, and rebuild manual equipment components

Accomplishments

- Successfully implemented a new maintenance system that reduced equipment downtime by 15% and improved overall equipment efficiency.

- Led a team of mechanics in overhauling a fleet of heavyduty machinery, resulting in a 20% increase in productivity and reduced maintenance costs.

- Developed and implemented a preventative maintenance program that extended the lifespan of equipment and reduced repair expenses.

- Collaborated with engineers to troubleshoot and resolve a critical design flaw in a new piece of machinery, preventing potential safety hazards.

- Trained and mentored junior mechanics, effectively transferring knowledge and skills, and ensuring a competent and efficient workforce.

Awards

- Awarded Top Mechanic of the Year for consistently exceeding performance standards and maintaining a high level of equipment uptime.

- Recognized for exceptional troubleshooting skills, resolving complex equipment malfunctions that prevented costly downtime.

- Awarded for outstanding safety practices, consistently exceeding industry standards and maintaining a safe work environment.

- Recognized for exceptional attention to detail, ensuring all equipment repairs met or exceeded manufacturer specifications.

Certificates

- Certified Maintenance and Reliability Technician (CMRT)

- Certified Millwright

- Occupational Safety and Health Administration (OSHA) 10-Hour General Industry

- Preventive Maintenance Certified (PMC)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Manual Equipment Mechanic

- Highlight your most relevant skills and experience in your resume, tailoring it specifically to the job description.

- Provide quantifiable results in your resume, demonstrating the impact of your work whenever possible.

- Proofread your resume carefully for any errors in grammar, spelling, or punctuation before submitting it.

- Consider including a cover letter that introduces yourself, expresses your interest in the position, and highlights your key qualifications.

Essential Experience Highlights for a Strong Manual Equipment Mechanic Resume

- Repaired and maintained a fleet of 100+ forklifts, scissor lifts, and pallet jacks, ensuring optimal functionality and safety within a warehouse environment

- Diagnosed and resolved complex mechanical issues with manual equipment, including hydraulic, electrical, and engine systems

- Performed preventive maintenance inspections and services on a monthly basis to minimize downtime and extend equipment lifespan

- Utilized specialized tools and equipment to inspect, disassemble, repair, and rebuild manual equipment components

- Collaborated with maintenance engineers and operators to identify and address performance issues with manual equipment

- Adhered to strict safety protocols and industry regulations while performing repairs and maintenance on manual equipment

- Maintained detailed records of all repair and maintenance activities, including parts replaced and labor hours

Frequently Asked Questions (FAQ’s) For Manual Equipment Mechanic

What are the primary responsibilities of a Manual Equipment Mechanic?

Manual Equipment Mechanics are responsible for maintaining and repairing a variety of manual equipment, including forklifts, scissor lifts, and pallet jacks. They diagnose and resolve mechanical issues, perform preventive maintenance, and ensure that equipment is operating safely and efficiently.

What skills are essential for a successful Manual Equipment Mechanic?

Successful Manual Equipment Mechanics typically possess strong mechanical skills, problem-solving abilities, and a thorough understanding of hydraulic, electrical, and engine systems. They are also skilled in using specialized tools and equipment and have a strong commitment to safety.

What is the job outlook for Manual Equipment Mechanics?

The job outlook for Manual Equipment Mechanics is expected to be positive in the coming years, with a projected growth rate of around 5%. This growth is attributed to the increasing use of material handling equipment in various industries.

What are the salary expectations for Manual Equipment Mechanics?

Salary expectations for Manual Equipment Mechanics vary depending on experience, location, and industry. According to the U.S. Bureau of Labor Statistics, the median annual salary for Manual Equipment Mechanics was around $48,000 in May 2020.

What are the career advancement opportunities for Manual Equipment Mechanics?

Manual Equipment Mechanics with experience and additional training may advance to supervisory or management roles. They may also specialize in a particular type of equipment or industry.

What are the educational requirements for becoming a Manual Equipment Mechanic?

Most Manual Equipment Mechanics have an associate degree or certification in automotive or diesel technology. Some employers may also consider candidates with relevant work experience in lieu of formal education.