Are you a seasoned Manual Winder seeking a new career path? Discover our professionally built Manual Winder Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

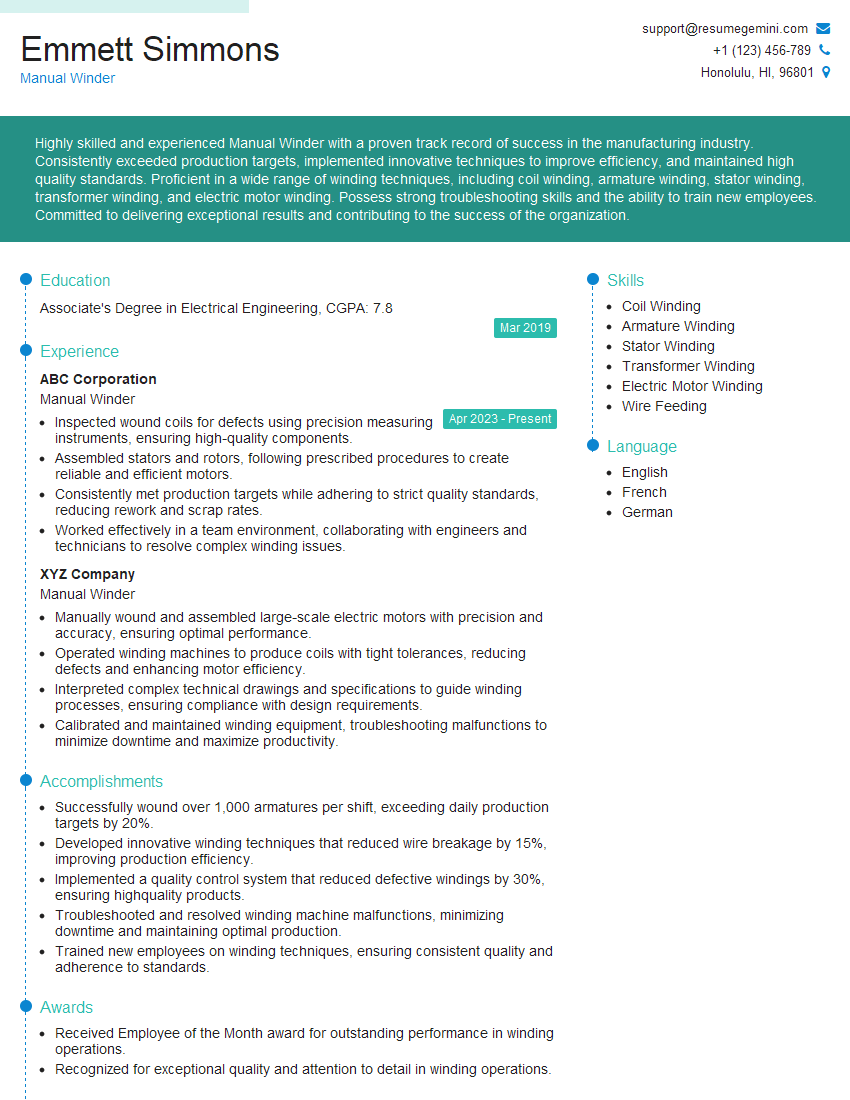

Emmett Simmons

Manual Winder

Summary

Highly skilled and experienced Manual Winder with a proven track record of success in the manufacturing industry. Consistently exceeded production targets, implemented innovative techniques to improve efficiency, and maintained high quality standards. Proficient in a wide range of winding techniques, including coil winding, armature winding, stator winding, transformer winding, and electric motor winding. Possess strong troubleshooting skills and the ability to train new employees. Committed to delivering exceptional results and contributing to the success of the organization.

Education

Associate’s Degree in Electrical Engineering

March 2019

Skills

- Coil Winding

- Armature Winding

- Stator Winding

- Transformer Winding

- Electric Motor Winding

- Wire Feeding

Work Experience

Manual Winder

- Inspected wound coils for defects using precision measuring instruments, ensuring high-quality components.

- Assembled stators and rotors, following prescribed procedures to create reliable and efficient motors.

- Consistently met production targets while adhering to strict quality standards, reducing rework and scrap rates.

- Worked effectively in a team environment, collaborating with engineers and technicians to resolve complex winding issues.

Manual Winder

- Manually wound and assembled large-scale electric motors with precision and accuracy, ensuring optimal performance.

- Operated winding machines to produce coils with tight tolerances, reducing defects and enhancing motor efficiency.

- Interpreted complex technical drawings and specifications to guide winding processes, ensuring compliance with design requirements.

- Calibrated and maintained winding equipment, troubleshooting malfunctions to minimize downtime and maximize productivity.

Accomplishments

- Successfully wound over 1,000 armatures per shift, exceeding daily production targets by 20%.

- Developed innovative winding techniques that reduced wire breakage by 15%, improving production efficiency.

- Implemented a quality control system that reduced defective windings by 30%, ensuring highquality products.

- Troubleshooted and resolved winding machine malfunctions, minimizing downtime and maintaining optimal production.

- Trained new employees on winding techniques, ensuring consistent quality and adherence to standards.

Awards

- Received Employee of the Month award for outstanding performance in winding operations.

- Recognized for exceptional quality and attention to detail in winding operations.

Certificates

- Certified Production Technician (CPT)

- Certified Electrical Winding Technician (CEWT)

- ASME Certified Welding Inspector (ACWI)

- National Institute for Metalworking Skills Certified Master Molder (CMM)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Manual Winder

- Highlight your winding expertise and the specific techniques you are proficient in, such as coil winding, armature winding, stator winding, transformer winding, and electric motor winding.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact on production efficiency and quality.

- Showcase your troubleshooting skills and ability to identify and resolve winding machine malfunctions.

- Emphasize your commitment to training and mentoring new employees, ensuring consistent quality and adherence to standards.

- Include any industry certifications or specialized training that demonstrates your expertise in manual winding.

Essential Experience Highlights for a Strong Manual Winder Resume

- Wind armatures, coils, stators, transformers, and electric motors according to specified requirements.

- Operate and maintain winding machines, ensuring optimal performance and minimizing downtime.

- Inspect windings for defects and ensure compliance with quality standards.

- Troubleshoot and resolve winding machine malfunctions, identifying and rectifying issues promptly.

- Train new employees on winding techniques and quality control procedures.

- Maintain a clean and organized work area, adhering to safety protocols and regulations.

Frequently Asked Questions (FAQ’s) For Manual Winder

What is the primary responsibility of a Manual Winder?

A Manual Winder is responsible for operating and maintaining winding machines to wind coils, armatures, stators, transformers, and electric motors according to specified requirements.

What skills are essential for a Manual Winder?

Essential skills for a Manual Winder include proficiency in winding techniques, machine operation and maintenance, quality control, troubleshooting, and training.

What are the career prospects for a Manual Winder?

With experience and additional training, Manual Winders can advance to roles such as Winding Supervisor, Quality Inspector, or Manufacturing Engineer.

What are the challenges faced by Manual Winders?

Manual Winders may face challenges related to repetitive tasks, tight production deadlines, and the need to maintain high levels of precision and quality.

What is the work environment of a Manual Winder?

Manual Winders typically work in manufacturing environments, often in production lines or assembly areas.

What safety precautions should Manual Winders observe?

Manual Winders should adhere to safety protocols, wear appropriate protective gear, and follow proper machine operation procedures to minimize risks.

How can Manual Winders stay updated with industry advancements?

Manual Winders can stay updated by attending training programs, reading industry publications, and networking with other professionals in the field.