Are you a seasoned Materials and Processes Manager seeking a new career path? Discover our professionally built Materials and Processes Manager Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

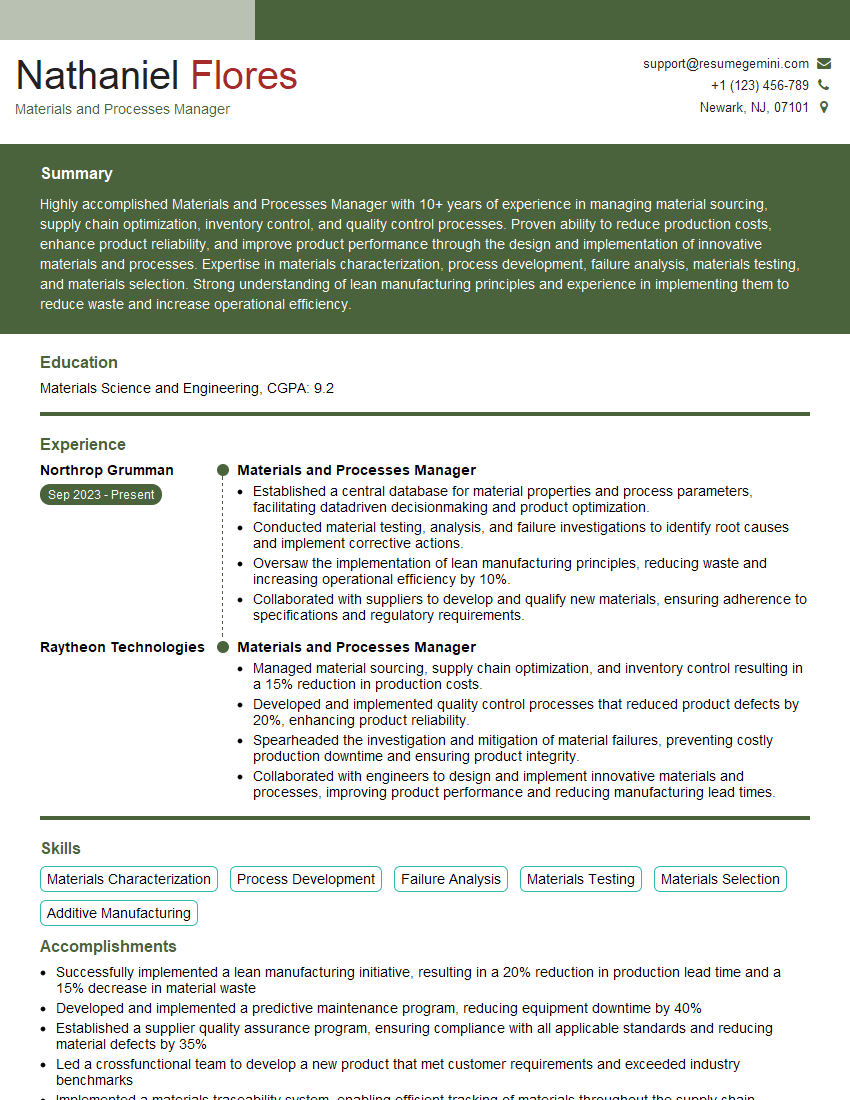

Nathaniel Flores

Materials and Processes Manager

Summary

Highly accomplished Materials and Processes Manager with 10+ years of experience in managing material sourcing, supply chain optimization, inventory control, and quality control processes. Proven ability to reduce production costs, enhance product reliability, and improve product performance through the design and implementation of innovative materials and processes. Expertise in materials characterization, process development, failure analysis, materials testing, and materials selection. Strong understanding of lean manufacturing principles and experience in implementing them to reduce waste and increase operational efficiency.

Education

Materials Science and Engineering

August 2019

Skills

- Materials Characterization

- Process Development

- Failure Analysis

- Materials Testing

- Materials Selection

- Additive Manufacturing

Work Experience

Materials and Processes Manager

- Established a central database for material properties and process parameters, facilitating datadriven decisionmaking and product optimization.

- Conducted material testing, analysis, and failure investigations to identify root causes and implement corrective actions.

- Oversaw the implementation of lean manufacturing principles, reducing waste and increasing operational efficiency by 10%.

- Collaborated with suppliers to develop and qualify new materials, ensuring adherence to specifications and regulatory requirements.

Materials and Processes Manager

- Managed material sourcing, supply chain optimization, and inventory control resulting in a 15% reduction in production costs.

- Developed and implemented quality control processes that reduced product defects by 20%, enhancing product reliability.

- Spearheaded the investigation and mitigation of material failures, preventing costly production downtime and ensuring product integrity.

- Collaborated with engineers to design and implement innovative materials and processes, improving product performance and reducing manufacturing lead times.

Accomplishments

- Successfully implemented a lean manufacturing initiative, resulting in a 20% reduction in production lead time and a 15% decrease in material waste

- Developed and implemented a predictive maintenance program, reducing equipment downtime by 40%

- Established a supplier quality assurance program, ensuring compliance with all applicable standards and reducing material defects by 35%

- Led a crossfunctional team to develop a new product that met customer requirements and exceeded industry benchmarks

- Implemented a materials traceability system, enabling efficient tracking of materials throughout the supply chain

Awards

- Recipient of the Annual Excellence Award in Materials Management

- Honored with the Industry Leadership Award for contributions to the field of materials science

- Recognized with the Innovation Award for developing a novel process that significantly improved product quality

- Recipient of the Best Practice Award for implementing a sustainable materials management program

Certificates

- ASQ Certified Quality Engineer (CQE)

- Six Sigma Black Belt

- PMI Project Management Professional (PMP)

- Certified Materials Scientist (CMS)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Materials and Processes Manager

Quantify your achievements.

Use specific numbers and metrics to demonstrate the impact of your work. For example, instead of saying “managed material sourcing,” say “managed material sourcing, resulting in a 15% reduction in production costs.”Highlight your skills and experience.

Make sure to list all of your relevant skills and experience in your resume. This will help potential employers see that you have the qualifications they need.Tailor your resume to each job you apply for.

Take the time to tailor your resume to each job you apply for. This will show potential employers that you are interested in their specific position and that you have the skills and experience they need.Proofread your resume carefully.

Before you submit your resume, proofread it carefully for any errors. This will help you make a good impression on potential employers.

Essential Experience Highlights for a Strong Materials and Processes Manager Resume

- Managed material sourcing, supply chain optimization, and inventory control resulting in a 15% reduction in production costs.

- Developed and implemented quality control processes that reduced product defects by 20%, enhancing product reliability.

- Spearheaded the investigation and mitigation of material failures, preventing costly production downtime and ensuring product integrity.

- Collaborated with engineers to design and implement innovative materials and processes, improving product performance and reducing manufacturing lead times.

- Established a central database for material properties and process parameters, facilitating data-driven decision-making and product optimization.

- Conducted material testing, analysis, and failure investigations to identify root causes and implement corrective actions.

- Oversaw the implementation of lean manufacturing principles, reducing waste and increasing operational efficiency by 10%.

Frequently Asked Questions (FAQ’s) For Materials and Processes Manager

What is a Materials and Processes Manager?

A Materials and Processes Manager is responsible for managing the materials and processes used in the manufacturing of a product. This includes managing material sourcing, supply chain optimization, inventory control, and quality control processes.

What are the key skills and experience required to be a Materials and Processes Manager?

The key skills and experience required to be a Materials and Processes Manager include materials characterization, process development, failure analysis, materials testing, materials selection, and additive manufacturing.

What are the key responsibilities of a Materials and Processes Manager?

The key responsibilities of a Materials and Processes Manager include managing material sourcing, supply chain optimization, inventory control, and quality control processes; developing and implementing new materials and processes; and investigating and mitigating material failures.

What is the job outlook for Materials and Processes Managers?

The job outlook for Materials and Processes Managers is expected to be good over the next few years. This is due to the increasing demand for new and innovative materials and processes in the manufacturing industry.

What is the average salary for a Materials and Processes Manager?

The average salary for a Materials and Processes Manager is around $85,000 per year.

What are the career advancement opportunities for Materials and Processes Managers?

Career advancement opportunities for Materials and Processes Managers include becoming a Senior Materials and Processes Manager, a Director of Materials and Processes, or a Vice President of Materials and Processes.