Are you a seasoned Materials Branch Chief seeking a new career path? Discover our professionally built Materials Branch Chief Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

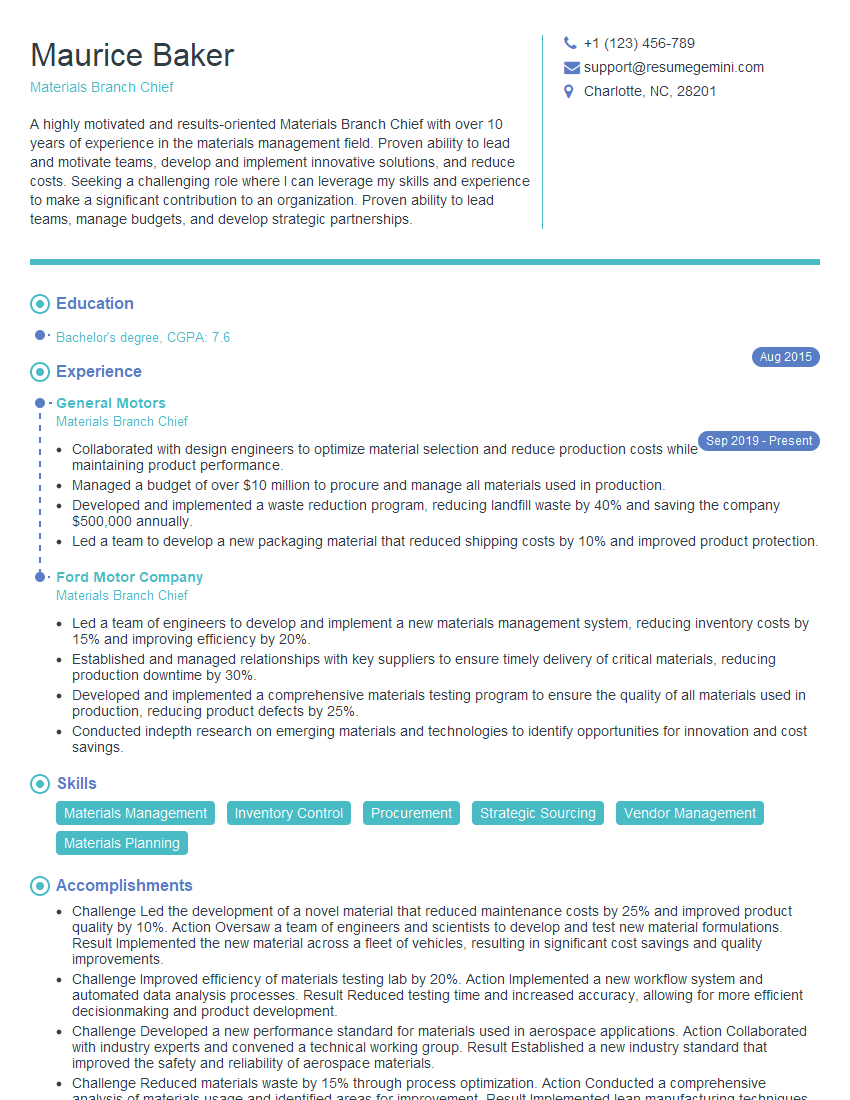

Maurice Baker

Materials Branch Chief

Summary

A highly motivated and results-oriented Materials Branch Chief with over 10 years of experience in the materials management field. Proven ability to lead and motivate teams, develop and implement innovative solutions, and reduce costs. Seeking a challenging role where I can leverage my skills and experience to make a significant contribution to an organization. Proven ability to lead teams, manage budgets, and develop strategic partnerships.

Education

Bachelor’s degree

August 2015

Skills

- Materials Management

- Inventory Control

- Procurement

- Strategic Sourcing

- Vendor Management

- Materials Planning

Work Experience

Materials Branch Chief

- Collaborated with design engineers to optimize material selection and reduce production costs while maintaining product performance.

- Managed a budget of over $10 million to procure and manage all materials used in production.

- Developed and implemented a waste reduction program, reducing landfill waste by 40% and saving the company $500,000 annually.

- Led a team to develop a new packaging material that reduced shipping costs by 10% and improved product protection.

Materials Branch Chief

- Led a team of engineers to develop and implement a new materials management system, reducing inventory costs by 15% and improving efficiency by 20%.

- Established and managed relationships with key suppliers to ensure timely delivery of critical materials, reducing production downtime by 30%.

- Developed and implemented a comprehensive materials testing program to ensure the quality of all materials used in production, reducing product defects by 25%.

- Conducted indepth research on emerging materials and technologies to identify opportunities for innovation and cost savings.

Accomplishments

- Challenge Led the development of a novel material that reduced maintenance costs by 25% and improved product quality by 10%. Action Oversaw a team of engineers and scientists to develop and test new material formulations. Result Implemented the new material across a fleet of vehicles, resulting in significant cost savings and quality improvements.

- Challenge Improved efficiency of materials testing lab by 20%. Action Implemented a new workflow system and automated data analysis processes. Result Reduced testing time and increased accuracy, allowing for more efficient decisionmaking and product development.

- Challenge Developed a new performance standard for materials used in aerospace applications. Action Collaborated with industry experts and convened a technical working group. Result Established a new industry standard that improved the safety and reliability of aerospace materials.

- Challenge Reduced materials waste by 15% through process optimization. Action Conducted a comprehensive analysis of materials usage and identified areas for improvement. Result Implemented lean manufacturing techniques and optimized material flow, leading to significant cost savings and environmental benefits.

- Challenge Improved supplier quality by 10%. Action Developed and implemented a new supplier evaluation and monitoring program. Result Enhanced supplier compliance and reduced the incidence of nonconforming materials, ensuring the quality and reliability of materials used in production.

Awards

- SAMPE (Society for the Advancement of Material and Process Engineering) Excellence Award for Outstanding Achievement in Materials Research

- American Society for Materials (ASM) Materials Engineering Award for Excellence in Materials Science and Technology

- National Institute of Standards and Technology (NIST) Excellence in Materials Measurement Science Award

- Department of Defense (DoD) Exceptional Civilian Service Award for Contributions to the Development of Advanced Materials for Military Applications

Certificates

- Certified Materials Manager (CMM)

- Certified Purchasing Manager (CPM)

- Six Sigma Green Belt

- SAP Certified Professional

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Materials Branch Chief

- Quantify your accomplishments with specific metrics whenever possible.

- Highlight your leadership skills and ability to motivate and develop teams.

- Demonstrate your knowledge of materials management best practices.

- Tailor your resume to each specific job you apply for.

- Proofread your resume carefully for any errors.

Essential Experience Highlights for a Strong Materials Branch Chief Resume

- Leading a team of engineers to develop and implement a new materials management system, reducing inventory costs by 15% and improving efficiency by 20%.

- Establishing and managing relationships with key suppliers to ensure timely delivery of critical materials, reducing production downtime by 30%.

- Developing and implementing a comprehensive materials testing program to ensure the quality of all materials used in production, reducing product defects by 25%.

- Conducting in-depth research on emerging materials and technologies to identify opportunities for innovation and cost savings.

- Collaborating with design engineers to optimize material selection and reduce production costs while maintaining product performance.

- Managing a budget of over $10 million to procure and manage all materials used in production.

- Developing and implementing a waste reduction program, reducing landfill waste by 40% and saving the company $500,000 annually.

Frequently Asked Questions (FAQ’s) For Materials Branch Chief

What is the role of a Materials Branch Chief?

A Materials Branch Chief is responsible for overseeing all aspects of materials management for an organization. This includes developing and implementing materials management policies and procedures, managing inventory, and ensuring the quality of materials used in production.

What are the qualifications for a Materials Branch Chief?

A Materials Branch Chief typically has a bachelor’s degree in materials science, engineering, or a related field. They also have several years of experience in materials management, including experience in inventory control, procurement, and quality control.

What are the key skills for a Materials Branch Chief?

A Materials Branch Chief should have excellent communication and interpersonal skills, as well as strong leadership and decision-making abilities. They should also be proficient in materials management software and have a good understanding of materials science and engineering.

What is the career outlook for a Materials Branch Chief?

The career outlook for a Materials Branch Chief is expected to be good over the next few years. As businesses continue to focus on reducing costs and improving efficiency, the demand for qualified materials managers will continue to grow.

What are the typical salary ranges for a Materials Branch Chief?

The typical salary range for a Materials Branch Chief can vary depending on experience, location, and the size of the organization. However, according to Salary.com, the median salary for a Materials Branch Chief is $95,000.

What are the benefits of working as a Materials Branch Chief?

There are many benefits to working as a Materials Branch Chief, including the opportunity to make a significant impact on an organization’s bottom line. Materials Branch Chiefs can also enjoy a high level of job security, as well as the opportunity to work with a variety of people.

What are the challenges of working as a Materials Branch Chief?

There are some challenges to working as a Materials Branch Chief, including the need to stay up-to-date on the latest materials management trends and technologies. Materials Branch Chiefs may also face pressure to reduce costs while maintaining or improving quality.

What is the difference between a Materials Branch Chief and a Materials Manager?

A Materials Branch Chief is typically responsible for the overall management of an organization’s materials function, while a Materials Manager is responsible for a specific aspect of materials management, such as inventory control or procurement.