Are you a seasoned Materials Inspector seeking a new career path? Discover our professionally built Materials Inspector Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

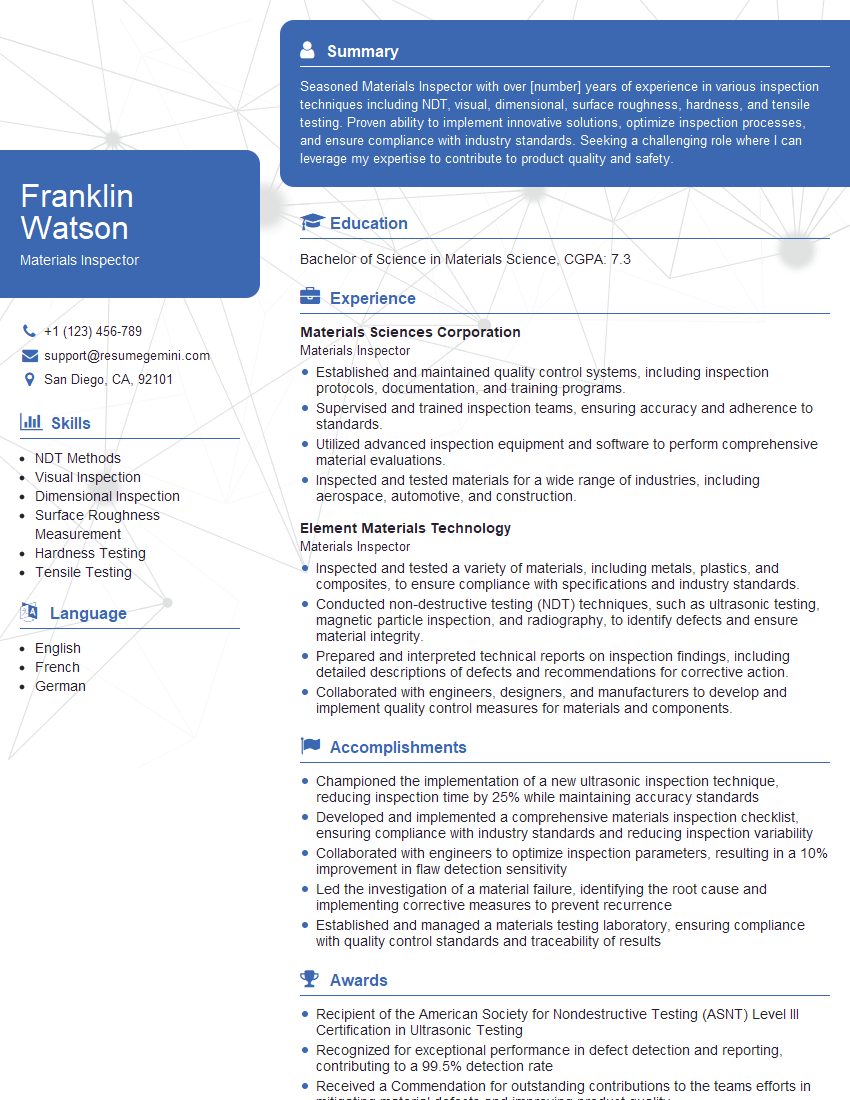

Franklin Watson

Materials Inspector

Summary

Seasoned Materials Inspector with over [number] years of experience in various inspection techniques including NDT, visual, dimensional, surface roughness, hardness, and tensile testing. Proven ability to implement innovative solutions, optimize inspection processes, and ensure compliance with industry standards. Seeking a challenging role where I can leverage my expertise to contribute to product quality and safety.

Education

Bachelor of Science in Materials Science

August 2019

Skills

- NDT Methods

- Visual Inspection

- Dimensional Inspection

- Surface Roughness Measurement

- Hardness Testing

- Tensile Testing

Work Experience

Materials Inspector

- Established and maintained quality control systems, including inspection protocols, documentation, and training programs.

- Supervised and trained inspection teams, ensuring accuracy and adherence to standards.

- Utilized advanced inspection equipment and software to perform comprehensive material evaluations.

- Inspected and tested materials for a wide range of industries, including aerospace, automotive, and construction.

Materials Inspector

- Inspected and tested a variety of materials, including metals, plastics, and composites, to ensure compliance with specifications and industry standards.

- Conducted non-destructive testing (NDT) techniques, such as ultrasonic testing, magnetic particle inspection, and radiography, to identify defects and ensure material integrity.

- Prepared and interpreted technical reports on inspection findings, including detailed descriptions of defects and recommendations for corrective action.

- Collaborated with engineers, designers, and manufacturers to develop and implement quality control measures for materials and components.

Accomplishments

- Championed the implementation of a new ultrasonic inspection technique, reducing inspection time by 25% while maintaining accuracy standards

- Developed and implemented a comprehensive materials inspection checklist, ensuring compliance with industry standards and reducing inspection variability

- Collaborated with engineers to optimize inspection parameters, resulting in a 10% improvement in flaw detection sensitivity

- Led the investigation of a material failure, identifying the root cause and implementing corrective measures to prevent recurrence

- Established and managed a materials testing laboratory, ensuring compliance with quality control standards and traceability of results

Awards

- Recipient of the American Society for Nondestructive Testing (ASNT) Level III Certification in Ultrasonic Testing

- Recognized for exceptional performance in defect detection and reporting, contributing to a 99.5% detection rate

- Received a Commendation for outstanding contributions to the teams efforts in mitigating material defects and improving product quality

- Honored with the National Institute for Certification in Engineering Technologies (NICET) Level III Certification in Materials Testing

Certificates

- ASNT Level II NDT Certification for Ultrasonic Testing

- ASNT Level II NDT Certification for Radiographic Testing

- ASNT Level II NDT Certification for Magnetic Particle Testing

- ASNT Level II NDT Certification for Liquid Penetrant Testing

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Materials Inspector

- Quantify your accomplishments using specific metrics whenever possible. For example, instead of saying ‘Improved inspection efficiency’, you could say ‘Reduced inspection time by 25% while maintaining accuracy standards.’

- Highlight your knowledge of industry-specific standards and regulations relevant to materials inspection.

- Showcase your ability to work independently and as part of a team, and emphasize your problem-solving and analytical skills.

- Tailor your resume to each job application by highlighting the skills and experience that are most relevant to the specific role you are applying for.

- Get feedback on your resume from a career counselor or experienced professional in the field.

Essential Experience Highlights for a Strong Materials Inspector Resume

- Conduct comprehensive materials inspections using a variety of NDT and conventional techniques to assess material properties, dimensions, and surface characteristics.

- Develop and implement inspection procedures and checklists to ensure adherence to industry standards and internal quality control protocols.

- Collaborate with engineers to optimize inspection parameters and enhance flaw detection sensitivity.

- Analyze inspection results, identify anomalies, and make informed judgments regarding material acceptability.

- Investigate material failures, determine root causes, and recommend corrective actions to prevent recurrence.

- Manage a materials testing laboratory, ensuring compliance with equipment calibration, traceability of results, and quality control standards.

- Provide technical support to production and engineering teams, offering guidance on materials selection, inspection techniques, and quality assurance.

Frequently Asked Questions (FAQ’s) For Materials Inspector

What are the typical duties of a Materials Inspector?

Materials Inspectors are responsible for inspecting raw materials, components, and finished products to ensure they meet specifications and quality standards. They use a variety of inspection techniques, including visual, dimensional, surface roughness, hardness, and tensile testing.

What are the educational requirements for becoming a Materials Inspector?

Most Materials Inspectors have a Bachelor’s degree in Materials Science, Engineering, or a related field. Some employers may also accept candidates with an Associate’s degree or equivalent experience.

What are the career prospects for Materials Inspectors?

Materials Inspectors can advance to supervisory or managerial positions within their company or organization. They may also specialize in a particular area of materials inspection, such as NDT or failure analysis.

What are the key skills required for a Materials Inspector?

Materials Inspectors need to have strong technical skills in materials science, inspection techniques, and quality control. They also need to be able to work independently and as part of a team, and have excellent communication and problem-solving skills.

What is the work environment like for a Materials Inspector?

Materials Inspectors typically work in a laboratory or production environment. They may be exposed to hazardous materials or conditions, so they must wear appropriate safety gear and follow safety procedures.

What are the salary expectations for a Materials Inspector?

The salary for a Materials Inspector can vary depending on experience, education, and location. According to Indeed, the average salary for a Materials Inspector in the United States is around $60,000 per year.