Are you a seasoned Materials Planner/Production Planner seeking a new career path? Discover our professionally built Materials Planner/Production Planner Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

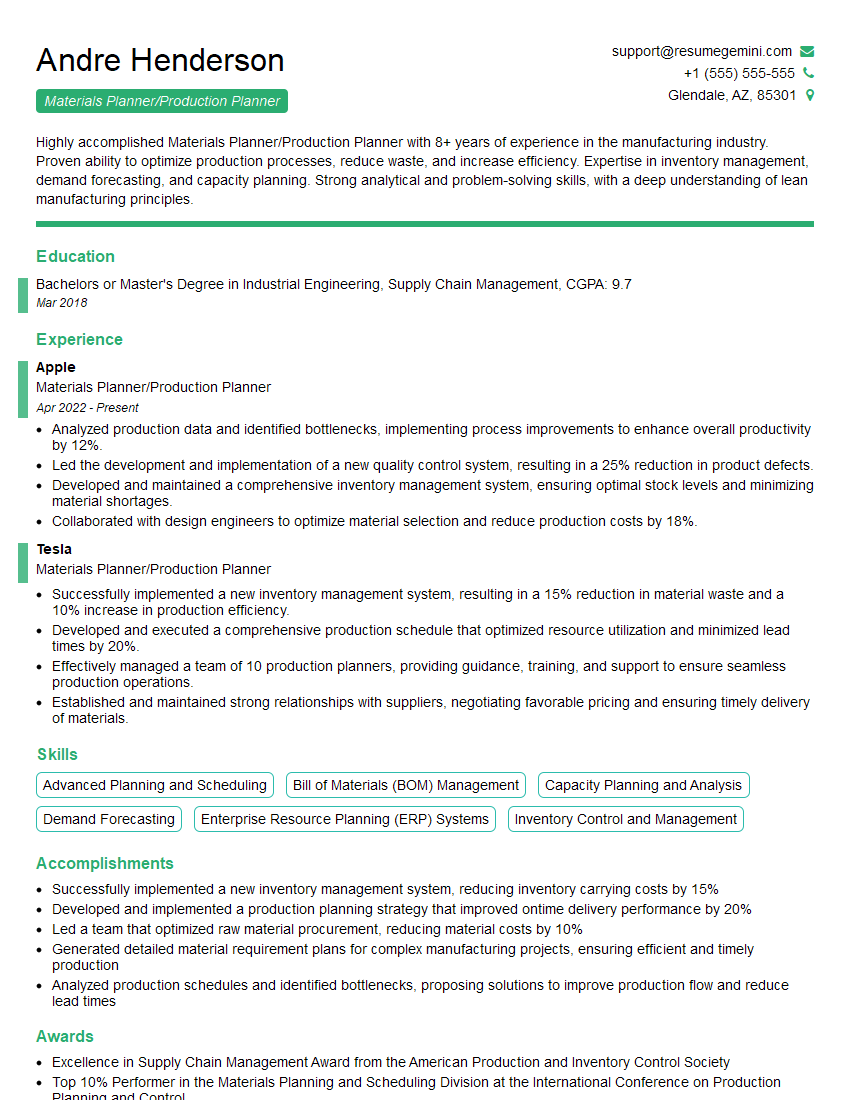

Andre Henderson

Materials Planner/Production Planner

Summary

Highly accomplished Materials Planner/Production Planner with 8+ years of experience in the manufacturing industry. Proven ability to optimize production processes, reduce waste, and increase efficiency. Expertise in inventory management, demand forecasting, and capacity planning. Strong analytical and problem-solving skills, with a deep understanding of lean manufacturing principles.

Education

Bachelors or Master’s Degree in Industrial Engineering, Supply Chain Management

March 2018

Skills

- Advanced Planning and Scheduling

- Bill of Materials (BOM) Management

- Capacity Planning and Analysis

- Demand Forecasting

- Enterprise Resource Planning (ERP) Systems

- Inventory Control and Management

Work Experience

Materials Planner/Production Planner

- Analyzed production data and identified bottlenecks, implementing process improvements to enhance overall productivity by 12%.

- Led the development and implementation of a new quality control system, resulting in a 25% reduction in product defects.

- Developed and maintained a comprehensive inventory management system, ensuring optimal stock levels and minimizing material shortages.

- Collaborated with design engineers to optimize material selection and reduce production costs by 18%.

Materials Planner/Production Planner

- Successfully implemented a new inventory management system, resulting in a 15% reduction in material waste and a 10% increase in production efficiency.

- Developed and executed a comprehensive production schedule that optimized resource utilization and minimized lead times by 20%.

- Effectively managed a team of 10 production planners, providing guidance, training, and support to ensure seamless production operations.

- Established and maintained strong relationships with suppliers, negotiating favorable pricing and ensuring timely delivery of materials.

Accomplishments

- Successfully implemented a new inventory management system, reducing inventory carrying costs by 15%

- Developed and implemented a production planning strategy that improved ontime delivery performance by 20%

- Led a team that optimized raw material procurement, reducing material costs by 10%

- Generated detailed material requirement plans for complex manufacturing projects, ensuring efficient and timely production

- Analyzed production schedules and identified bottlenecks, proposing solutions to improve production flow and reduce lead times

Awards

- Excellence in Supply Chain Management Award from the American Production and Inventory Control Society

- Top 10% Performer in the Materials Planning and Scheduling Division at the International Conference on Production Planning and Control

- Employee of the Year Award for Outstanding Contributions to Inventory Management and Production Planning

Certificates

- American Production and Inventory Control Society (APICS) Certified Production and Inventory Manager (CPIM)

- APICS Certified Supply Chain Professional (CSCP)

- Institute for Supply Management (ISM) Certified Professional in Supply Management (CPSM)

- Lean Six Sigma Green Belt Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Materials Planner/Production Planner

- Highlight your experience in implementing and optimizing inventory management systems.

- Quantify your accomplishments with specific metrics, such as percentage reductions in waste or improvements in efficiency.

- Emphasize your ability to collaborate effectively with cross-functional teams, including design engineers and suppliers.

- Showcase your understanding of lean manufacturing principles and your ability to apply them to improve production processes.

Essential Experience Highlights for a Strong Materials Planner/Production Planner Resume

- Plan and schedule production operations to meet customer demand and optimize resource utilization.

- Manage inventory levels to ensure optimal stock levels and minimize material shortages.

- Develop and implement production schedules that minimize lead times and improve production efficiency.

- Collaborate with design engineers to optimize material selection and reduce production costs.

- Analyze production data to identify bottlenecks and implement process improvements.

- Establish and maintain strong relationships with suppliers to ensure timely delivery of materials at favorable pricing.

- Develop and maintain inventory management systems to ensure accurate and efficient tracking of materials.

- Lead and motivate a team of production planners.

Frequently Asked Questions (FAQ’s) For Materials Planner/Production Planner

What is the role of a Materials Planner/Production Planner?

Materials Planners/Production Planners are responsible for planning and scheduling production operations to meet customer demand while optimizing resource utilization. They manage inventory levels, develop production schedules, collaborate with design engineers, and analyze production data to identify and implement process improvements.

What are the essential skills for a Materials Planner/Production Planner?

Essential skills for Materials Planners/Production Planners include advanced planning and scheduling, bill of materials (BOM) management, capacity planning and analysis, demand forecasting, enterprise resource planning (ERP) systems, and inventory control and management.

What industries employ Materials Planners/Production Planners?

Materials Planners/Production Planners are employed in various industries, including manufacturing, automotive, aerospace, electronics, and pharmaceuticals.

What is the career path for a Materials Planner/Production Planner?

Materials Planners/Production Planners can advance to roles such as Production Manager, Supply Chain Manager, or Operations Manager.

What are the challenges faced by Materials Planners/Production Planners?

Common challenges faced by Materials Planners/Production Planners include managing supply chain disruptions, optimizing production schedules in a dynamic environment, and ensuring product quality while meeting customer demand.

What are the key trends in the Materials Planning/Production Planning field?

Key trends in the Materials Planning/Production Planning field include the adoption of advanced technologies such as artificial intelligence (AI) and machine learning (ML) for demand forecasting and inventory optimization, increased focus on sustainability and waste reduction, and the growing importance of collaboration and data sharing across the supply chain.

What are the professional organizations and certifications for Materials Planners/Production Planners?

Relevant professional organizations for Materials Planners/Production Planners include the American Production and Inventory Control Society (APICS) and the Institute for Supply Management (ISM). APICS offers the Certified in Production and Inventory Management (CPIM) certification, while ISM offers the Certified Professional in Supply Management (CPSM) certification.