Are you a seasoned Materials Planner seeking a new career path? Discover our professionally built Materials Planner Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

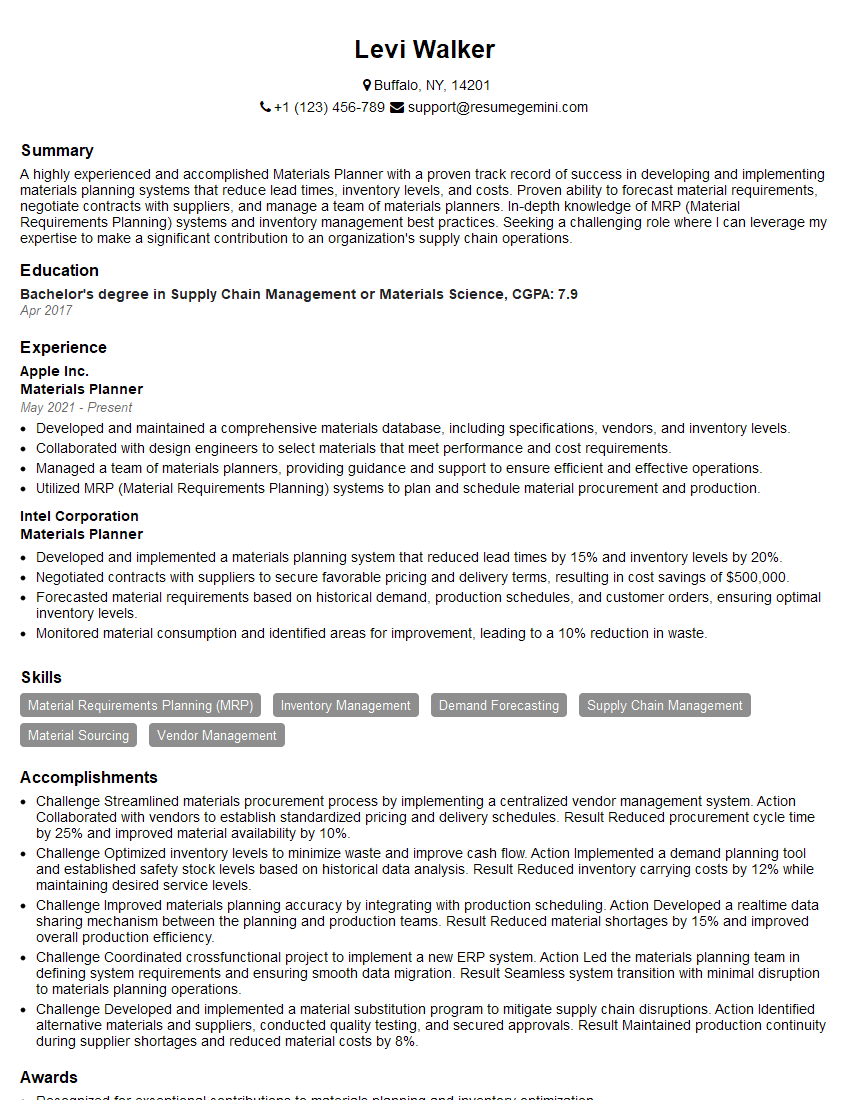

Levi Walker

Materials Planner

Summary

A highly experienced and accomplished Materials Planner with a proven track record of success in developing and implementing materials planning systems that reduce lead times, inventory levels, and costs. Proven ability to forecast material requirements, negotiate contracts with suppliers, and manage a team of materials planners. In-depth knowledge of MRP (Material Requirements Planning) systems and inventory management best practices. Seeking a challenging role where I can leverage my expertise to make a significant contribution to an organization’s supply chain operations.

Education

Bachelor’s degree in Supply Chain Management or Materials Science

April 2017

Skills

- Material Requirements Planning (MRP)

- Inventory Management

- Demand Forecasting

- Supply Chain Management

- Material Sourcing

- Vendor Management

Work Experience

Materials Planner

- Developed and maintained a comprehensive materials database, including specifications, vendors, and inventory levels.

- Collaborated with design engineers to select materials that meet performance and cost requirements.

- Managed a team of materials planners, providing guidance and support to ensure efficient and effective operations.

- Utilized MRP (Material Requirements Planning) systems to plan and schedule material procurement and production.

Materials Planner

- Developed and implemented a materials planning system that reduced lead times by 15% and inventory levels by 20%.

- Negotiated contracts with suppliers to secure favorable pricing and delivery terms, resulting in cost savings of $500,000.

- Forecasted material requirements based on historical demand, production schedules, and customer orders, ensuring optimal inventory levels.

- Monitored material consumption and identified areas for improvement, leading to a 10% reduction in waste.

Accomplishments

- Challenge Streamlined materials procurement process by implementing a centralized vendor management system. Action Collaborated with vendors to establish standardized pricing and delivery schedules. Result Reduced procurement cycle time by 25% and improved material availability by 10%.

- Challenge Optimized inventory levels to minimize waste and improve cash flow. Action Implemented a demand planning tool and established safety stock levels based on historical data analysis. Result Reduced inventory carrying costs by 12% while maintaining desired service levels.

- Challenge Improved materials planning accuracy by integrating with production scheduling. Action Developed a realtime data sharing mechanism between the planning and production teams. Result Reduced material shortages by 15% and improved overall production efficiency.

- Challenge Coordinated crossfunctional project to implement a new ERP system. Action Led the materials planning team in defining system requirements and ensuring smooth data migration. Result Seamless system transition with minimal disruption to materials planning operations.

- Challenge Developed and implemented a material substitution program to mitigate supply chain disruptions. Action Identified alternative materials and suppliers, conducted quality testing, and secured approvals. Result Maintained production continuity during supplier shortages and reduced material costs by 8%.

Awards

- Recognized for exceptional contributions to materials planning and inventory optimization.

- Received the Supplier Excellence Award for fostering strategic supplier partnerships and reducing material costs by 15%.

- Honored with the Project Management Award for successfully implementing a materials planning system that improved material availability by 20%.

- Recognized for Excellence in Materials Management by the Association for Supply Chain Management (ASCM).

Certificates

- Certified Materials and Resource Professional (CMRP)

- Certified Supply Chain Professional (CSCP)

- Certified Production and Inventory Manager (CPIM)

- Certified Six Sigma Green Belt

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Materials Planner

- Highlight your experience in developing and implementing materials planning systems that have resulted in measurable improvements in lead times, inventory levels, and costs.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate the impact of your work.

- Showcase your knowledge of MRP (Material Requirements Planning) systems and inventory management best practices.

- Emphasize your ability to negotiate contracts with suppliers and manage a team of materials planners.

Essential Experience Highlights for a Strong Materials Planner Resume

- Develop and implement materials planning systems to reduce lead times and inventory levels.

- Forecast material requirements based on historical demand, production schedules, and customer orders.

- Negotiate contracts with suppliers to secure favorable pricing and delivery terms.

- Monitor material consumption and identify areas for improvement to reduce waste.

- Develop and maintain a comprehensive materials database, including specifications, vendors, and inventory levels.

- Collaborate with design engineers to select materials that meet performance and cost requirements.

Frequently Asked Questions (FAQ’s) For Materials Planner

What is the main responsibility of a Materials Planner?

The main responsibility of a Materials Planner is to ensure that the right materials are available, in the right quantity, at the right time, and at the right cost to support production and operations.

What skills are required to be a Materials Planner?

Key skills required for a Materials Planner include: Material Requirements Planning (MRP), Inventory Management, Demand Forecasting, Supply Chain Management, Material Sourcing, and Vendor Management.

What is the career path for a Materials Planner?

With experience and additional qualifications, Materials Planners can advance to roles such as Inventory Manager, Supply Chain Manager, or Purchasing Manager.

What is the job outlook for Materials Planners?

The job outlook for Materials Planners is expected to grow in the coming years due to the increasing complexity of global supply chains and the need for efficient inventory management.

What are the challenges faced by Materials Planners?

Materials Planners face challenges such as managing multiple suppliers, dealing with fluctuating demand, and ensuring compliance with regulatory requirements.