Are you a seasoned Melt Helper seeking a new career path? Discover our professionally built Melt Helper Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

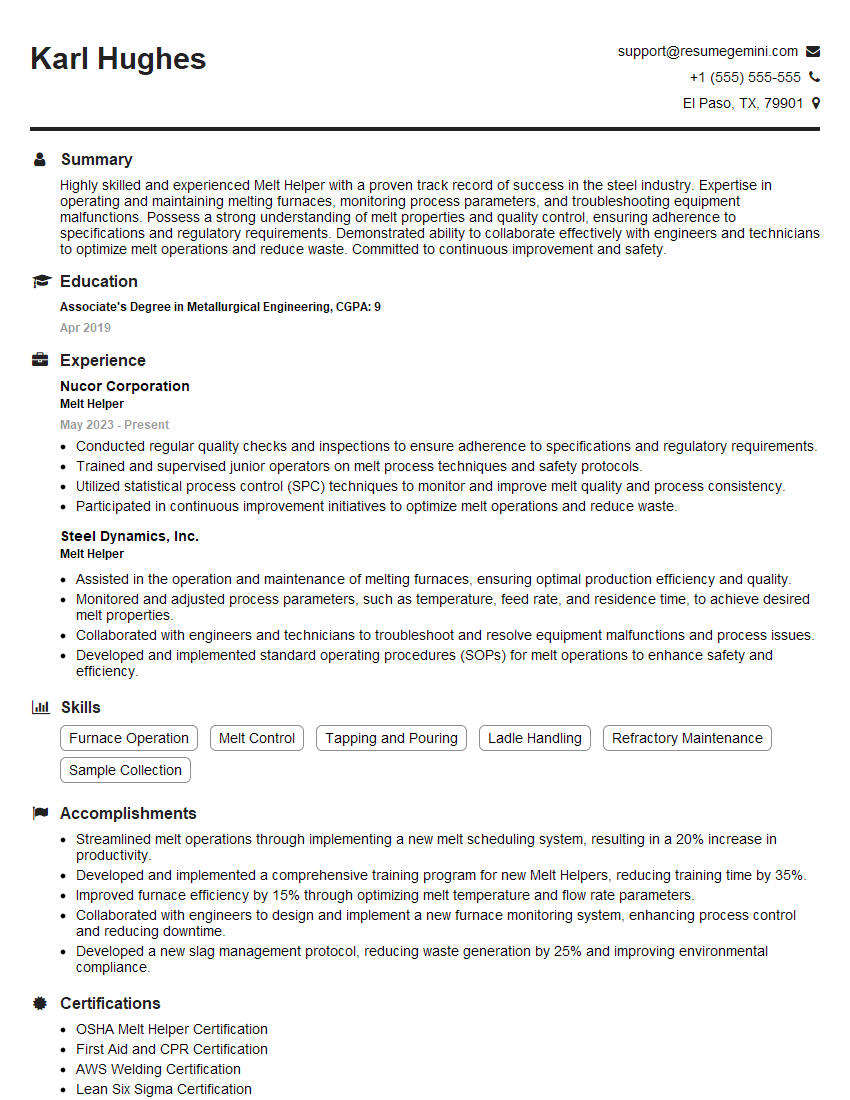

Karl Hughes

Melt Helper

Summary

Highly skilled and experienced Melt Helper with a proven track record of success in the steel industry. Expertise in operating and maintaining melting furnaces, monitoring process parameters, and troubleshooting equipment malfunctions. Possess a strong understanding of melt properties and quality control, ensuring adherence to specifications and regulatory requirements. Demonstrated ability to collaborate effectively with engineers and technicians to optimize melt operations and reduce waste. Committed to continuous improvement and safety.

Education

Associate’s Degree in Metallurgical Engineering

April 2019

Skills

- Furnace Operation

- Melt Control

- Tapping and Pouring

- Ladle Handling

- Refractory Maintenance

- Sample Collection

Work Experience

Melt Helper

- Conducted regular quality checks and inspections to ensure adherence to specifications and regulatory requirements.

- Trained and supervised junior operators on melt process techniques and safety protocols.

- Utilized statistical process control (SPC) techniques to monitor and improve melt quality and process consistency.

- Participated in continuous improvement initiatives to optimize melt operations and reduce waste.

Melt Helper

- Assisted in the operation and maintenance of melting furnaces, ensuring optimal production efficiency and quality.

- Monitored and adjusted process parameters, such as temperature, feed rate, and residence time, to achieve desired melt properties.

- Collaborated with engineers and technicians to troubleshoot and resolve equipment malfunctions and process issues.

- Developed and implemented standard operating procedures (SOPs) for melt operations to enhance safety and efficiency.

Accomplishments

- Streamlined melt operations through implementing a new melt scheduling system, resulting in a 20% increase in productivity.

- Developed and implemented a comprehensive training program for new Melt Helpers, reducing training time by 35%.

- Improved furnace efficiency by 15% through optimizing melt temperature and flow rate parameters.

- Collaborated with engineers to design and implement a new furnace monitoring system, enhancing process control and reducing downtime.

- Developed a new slag management protocol, reducing waste generation by 25% and improving environmental compliance.

Certificates

- OSHA Melt Helper Certification

- First Aid and CPR Certification

- AWS Welding Certification

- Lean Six Sigma Certification

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Melt Helper

Highlight your technical skills.

Emphasize your experience in operating and maintaining melting furnaces, as well as your knowledge of process parameters and quality control.Showcase your problem-solving abilities.

Describe your experience in troubleshooting and resolving equipment malfunctions and process issues.Quantify your accomplishments.

Use specific metrics to demonstrate the impact of your work, such as increased production efficiency or reduced waste.Demonstrate your commitment to safety.

Highlight your understanding of safety protocols and your commitment to maintaining a safe work environment.

Essential Experience Highlights for a Strong Melt Helper Resume

- – Assisted in the operation and maintenance of melting furnaces, ensuring optimal production efficiency and quality.

- – Monitored and adjusted process parameters, such as temperature, feed rate, and residence time, to achieve desired melt properties.

- – Collaborated with engineers and technicians to troubleshoot and resolve equipment malfunctions and process issues.

- – Developed and implemented standard operating procedures (SOPs) for melt operations to enhance safety and efficiency.

- – Conducted regular quality checks and inspections to ensure adherence to specifications and regulatory requirements.

- – Utilized statistical process control (SPC) techniques to monitor and improve melt quality and process consistency.

- – Participated in continuous improvement initiatives to optimize melt operations and reduce waste.

Frequently Asked Questions (FAQ’s) For Melt Helper

What are the key responsibilities of a Melt Helper?

The key responsibilities of a Melt Helper include operating and maintaining melting furnaces, monitoring process parameters, troubleshooting equipment malfunctions, developing and implementing SOPs, conducting quality checks and inspections, and participating in continuous improvement initiatives.

What qualifications are required to become a Melt Helper?

Typically, a Melt Helper requires an Associate’s Degree in Metallurgical Engineering or a related field, along with experience in operating and maintaining melting furnaces.

What are the career prospects for a Melt Helper?

Melt Helpers can advance to positions such as Melt Operator, Furnace Supervisor, or even Production Manager with experience and additional training.

What is the work environment of a Melt Helper like?

Melt Helpers typically work in a hot and noisy environment, with potential exposure to molten metal and other hazardous materials.

What are the safety precautions that a Melt Helper must take?

Melt Helpers must wear appropriate personal protective equipment (PPE), follow safety protocols, and be aware of the potential hazards associated with their work environment.

What is the importance of quality control in the role of a Melt Helper?

Quality control is crucial for Melt Helpers to ensure that the molten metal meets the required specifications and regulatory requirements, preventing defects and maintaining product quality.

How does a Melt Helper contribute to continuous improvement initiatives?

Melt Helpers participate in continuous improvement initiatives by identifying areas for optimization, implementing new processes or technologies, and monitoring results to enhance efficiency and reduce waste.

What soft skills are important for a successful Melt Helper?

Successful Melt Helpers possess strong attention to detail, problem-solving abilities, teamwork skills, and a commitment to safety.