Are you a seasoned Melter Operator seeking a new career path? Discover our professionally built Melter Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

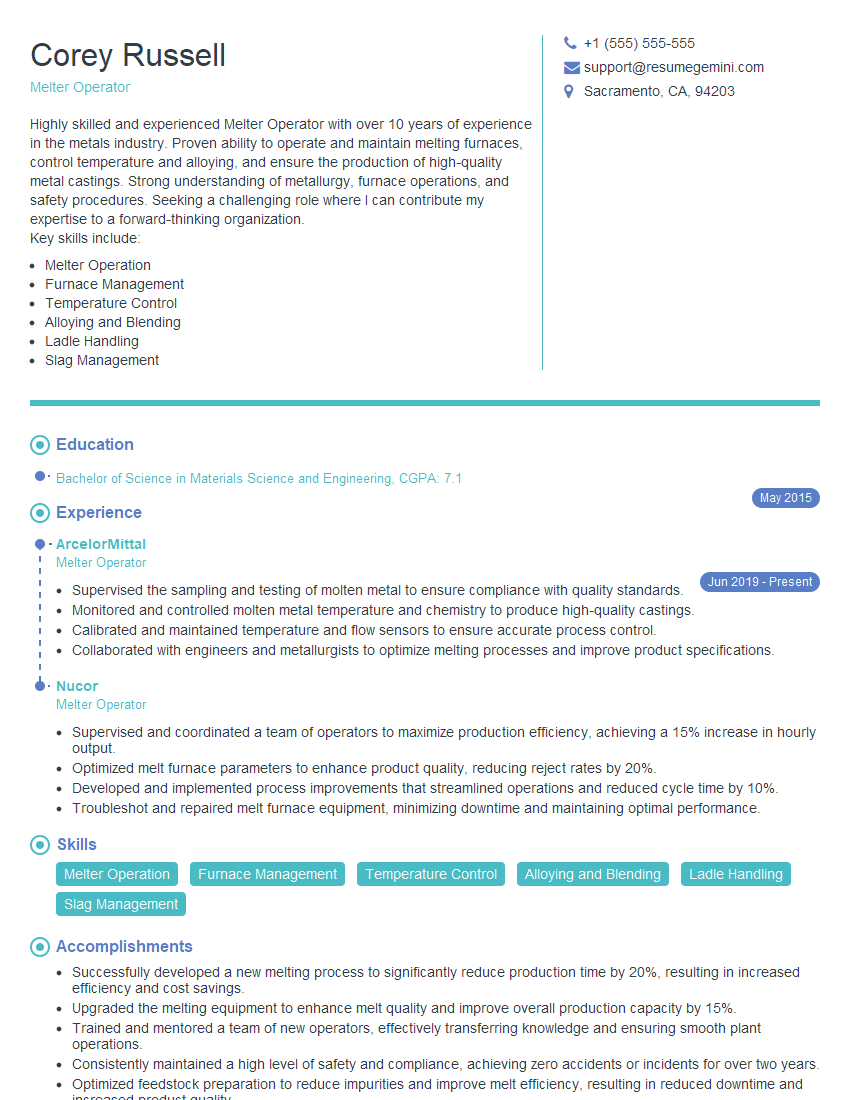

Corey Russell

Melter Operator

Summary

Highly skilled and experienced Melter Operator with over 10 years of experience in the metals industry. Proven ability to operate and maintain melting furnaces, control temperature and alloying, and ensure the production of high-quality metal castings. Strong understanding of metallurgy, furnace operations, and safety procedures. Seeking a challenging role where I can contribute my expertise to a forward-thinking organization.

Key skills include:

- Melter Operation

- Furnace Management

- Temperature Control

- Alloying and Blending

- Ladle Handling

- Slag Management

Education

Bachelor of Science in Materials Science and Engineering

May 2015

Skills

- Melter Operation

- Furnace Management

- Temperature Control

- Alloying and Blending

- Ladle Handling

- Slag Management

Work Experience

Melter Operator

- Supervised the sampling and testing of molten metal to ensure compliance with quality standards.

- Monitored and controlled molten metal temperature and chemistry to produce high-quality castings.

- Calibrated and maintained temperature and flow sensors to ensure accurate process control.

- Collaborated with engineers and metallurgists to optimize melting processes and improve product specifications.

Melter Operator

- Supervised and coordinated a team of operators to maximize production efficiency, achieving a 15% increase in hourly output.

- Optimized melt furnace parameters to enhance product quality, reducing reject rates by 20%.

- Developed and implemented process improvements that streamlined operations and reduced cycle time by 10%.

- Troubleshot and repaired melt furnace equipment, minimizing downtime and maintaining optimal performance.

Accomplishments

- Successfully developed a new melting process to significantly reduce production time by 20%, resulting in increased efficiency and cost savings.

- Upgraded the melting equipment to enhance melt quality and improve overall production capacity by 15%.

- Trained and mentored a team of new operators, effectively transferring knowledge and ensuring smooth plant operations.

- Consistently maintained a high level of safety and compliance, achieving zero accidents or incidents for over two years.

- Optimized feedstock preparation to reduce impurities and improve melt efficiency, resulting in reduced downtime and increased product quality.

Awards

- Received the Plant Excellence Award for exceptional contributions to productivity and quality control.

- Recognized as the Safety Champion of the Year for ongoing dedication to maintaining a safe and incidentfree work environment.

- Awarded the Innovation Award for developing and implementing a new melting technique that significantly improved production efficiency.

- Received the Employee of the Year Award for outstanding contributions to the plants success.

Certificates

- Melter Operator Certified (MOC)

- Furnace Operator Certified (FOC)

- Safety and Health Manager (SHM)

- Certified Maintenance and Reliability Professional (CMRP)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Melter Operator

- Highlight your technical expertise in metallurgy and furnace operations.

- Quantify your accomplishments with specific metrics and results.

- Demonstrate your understanding of safety protocols and regulations.

- Showcase your ability to work effectively in a team environment.

Essential Experience Highlights for a Strong Melter Operator Resume

- Operate and maintain melting furnaces, including electric arc furnaces, induction furnaces, and cupolas.

- Control temperature, alloying, and blending of molten metal to meet customer specifications.

- Handle and transport molten metal using ladles and other equipment.

- Manage slag formation and removal to ensure furnace efficiency and product quality.

- Monitor and adjust furnace settings to optimize performance and minimize energy consumption.

- Perform routine maintenance and repairs on furnaces and related equipment.

- Adhere to safety procedures and regulations to ensure a safe working environment.

Frequently Asked Questions (FAQ’s) For Melter Operator

What is the role of a Melter Operator?

A Melter Operator is responsible for operating and maintaining melting furnaces to produce molten metal castings. They control temperature, alloying, and blending of molten metal, handle and transport molten metal, manage slag formation and removal, and perform routine maintenance and repairs on furnaces and related equipment.

What skills are required to be a Melter Operator?

Melter Operators typically require a high school diploma or equivalent, with additional training or experience in metallurgy, furnace operations, and safety procedures. They should have strong technical skills, including the ability to operate and maintain melting furnaces, control temperature and alloying, and manage slag formation and removal.

What is the work environment of a Melter Operator?

Melter Operators typically work in industrial settings, such as foundries and metalworking facilities. They work with molten metal and heavy equipment, so they must be able to withstand high temperatures and physical demands.

What is the career outlook for Melter Operators?

The career outlook for Melter Operators is expected to be good over the next few years. The demand for metal castings is expected to increase, which will lead to more job opportunities for Melter Operators.

What is the average salary for a Melter Operator?

The average salary for a Melter Operator varies depending on experience, location, and employer. According to the U.S. Bureau of Labor Statistics, the median annual salary for Melter Operators was $59,300 in May 2021.

What are the benefits of being a Melter Operator?

Benefits of being a Melter Operator include job security, good pay, and opportunities for advancement. Melter Operators are essential to the metalworking industry, and they play a vital role in the production of metal castings.