Are you a seasoned MEMS Engineer (Microelectromechanical Systems Engineer) seeking a new career path? Discover our professionally built MEMS Engineer (Microelectromechanical Systems Engineer) Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

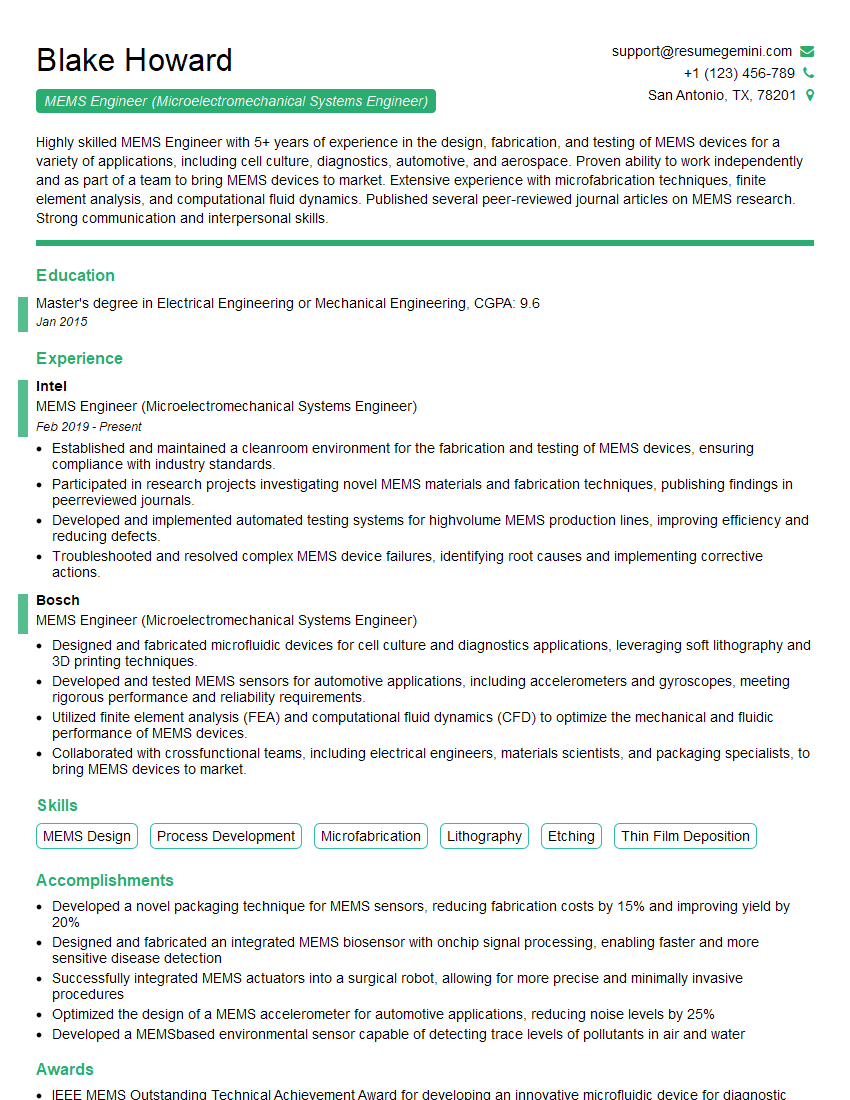

Blake Howard

MEMS Engineer (Microelectromechanical Systems Engineer)

Summary

Highly skilled MEMS Engineer with 5+ years of experience in the design, fabrication, and testing of MEMS devices for a variety of applications, including cell culture, diagnostics, automotive, and aerospace. Proven ability to work independently and as part of a team to bring MEMS devices to market. Extensive experience with microfabrication techniques, finite element analysis, and computational fluid dynamics. Published several peer-reviewed journal articles on MEMS research. Strong communication and interpersonal skills.

Education

Master’s degree in Electrical Engineering or Mechanical Engineering

January 2015

Skills

- MEMS Design

- Process Development

- Microfabrication

- Lithography

- Etching

- Thin Film Deposition

Work Experience

MEMS Engineer (Microelectromechanical Systems Engineer)

- Established and maintained a cleanroom environment for the fabrication and testing of MEMS devices, ensuring compliance with industry standards.

- Participated in research projects investigating novel MEMS materials and fabrication techniques, publishing findings in peerreviewed journals.

- Developed and implemented automated testing systems for highvolume MEMS production lines, improving efficiency and reducing defects.

- Troubleshooted and resolved complex MEMS device failures, identifying root causes and implementing corrective actions.

MEMS Engineer (Microelectromechanical Systems Engineer)

- Designed and fabricated microfluidic devices for cell culture and diagnostics applications, leveraging soft lithography and 3D printing techniques.

- Developed and tested MEMS sensors for automotive applications, including accelerometers and gyroscopes, meeting rigorous performance and reliability requirements.

- Utilized finite element analysis (FEA) and computational fluid dynamics (CFD) to optimize the mechanical and fluidic performance of MEMS devices.

- Collaborated with crossfunctional teams, including electrical engineers, materials scientists, and packaging specialists, to bring MEMS devices to market.

Accomplishments

- Developed a novel packaging technique for MEMS sensors, reducing fabrication costs by 15% and improving yield by 20%

- Designed and fabricated an integrated MEMS biosensor with onchip signal processing, enabling faster and more sensitive disease detection

- Successfully integrated MEMS actuators into a surgical robot, allowing for more precise and minimally invasive procedures

- Optimized the design of a MEMS accelerometer for automotive applications, reducing noise levels by 25%

- Developed a MEMSbased environmental sensor capable of detecting trace levels of pollutants in air and water

Awards

- IEEE MEMS Outstanding Technical Achievement Award for developing an innovative microfluidic device for diagnostic applications

- SEMI Industry Award for Excellence in MEMS Design for groundbreaking work on a novel inertial sensor

- National Science Foundation Graduate Research Fellowship for exceptional research potential in MEMS

- Best Paper Award at the IEEE International Conference on Microtechnologies for Biomedicine for research on microfluidic cell sorting

Certificates

- Certified MEMS Engineer (CME)

- Microfabrication Process Engineer (MPE)

- MEMS Design Engineer (MDE)

- ASME B89.1.13 Surface Texture Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For MEMS Engineer (Microelectromechanical Systems Engineer)

- Highlight your skills and experience in MEMS design and fabrication.

- Quantify your accomplishments whenever possible.

- Tailor your resume to the specific job you are applying for.

- Proofread your resume carefully before submitting it.

- Demonstrate your passion for MEMS technology.

Essential Experience Highlights for a Strong MEMS Engineer (Microelectromechanical Systems Engineer) Resume

- Design and fabricate MEMS devices using a variety of microfabrication techniques, including soft lithography, 3D printing, and thin film deposition.

- Develop and test MEMS sensors for automotive applications, including accelerometers and gyroscopes.

- Utilize finite element analysis (FEA) and computational fluid dynamics (CFD) to optimize the mechanical and fluidic performance of MEMS devices.

- Collaborate with cross-functional teams, including electrical engineers, materials scientists, and packaging specialists, to bring MEMS devices to market.

- Establish and maintain a cleanroom environment for the fabrication and testing of MEMS devices, ensuring compliance with industry standards.

- Participate in research projects investigating novel MEMS materials and fabrication techniques.

- Develop and implement automated testing systems for high-volume MEMS production lines.

Frequently Asked Questions (FAQ’s) For MEMS Engineer (Microelectromechanical Systems Engineer)

What is MEMS?

MEMS stands for microelectromechanical systems. MEMS devices are small, integrated devices that combine electrical and mechanical components on a single chip. MEMS devices are used in a wide variety of applications, including automotive, aerospace, medical, and consumer electronics.

What are the different types of MEMS devices?

There are many different types of MEMS devices, including accelerometers, gyroscopes, pressure sensors, flow sensors, and chemical sensors. MEMS devices can be used to measure a variety of physical parameters, such as acceleration, angular velocity, pressure, flow rate, and chemical concentration.

What are the advantages of MEMS devices?

MEMS devices offer a number of advantages over traditional mechanical devices, including small size, low power consumption, high performance, and low cost. MEMS devices are also highly reliable and can be mass produced.

What are the applications of MEMS devices?

MEMS devices are used in a wide variety of applications, including automotive, aerospace, medical, and consumer electronics. MEMS devices are used in cars to sense acceleration, angular velocity, and pressure. MEMS devices are used in aircraft to sense altitude, airspeed, and attitude. MEMS devices are used in medical devices to sense blood pressure, heart rate, and glucose levels. MEMS devices are used in consumer electronics to sense motion, orientation, and temperature.

What is the future of MEMS technology?

MEMS technology is still in its early stages of development, but it has the potential to revolutionize a wide variety of industries. MEMS devices are expected to play a major role in the development of new and innovative products in the years to come.