Are you a seasoned Metal and Plastic Nonelectrolytic Plating and Coating Machine Operator/Tender seeking a new career path? Discover our professionally built Metal and Plastic Nonelectrolytic Plating and Coating Machine Operator/Tender Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

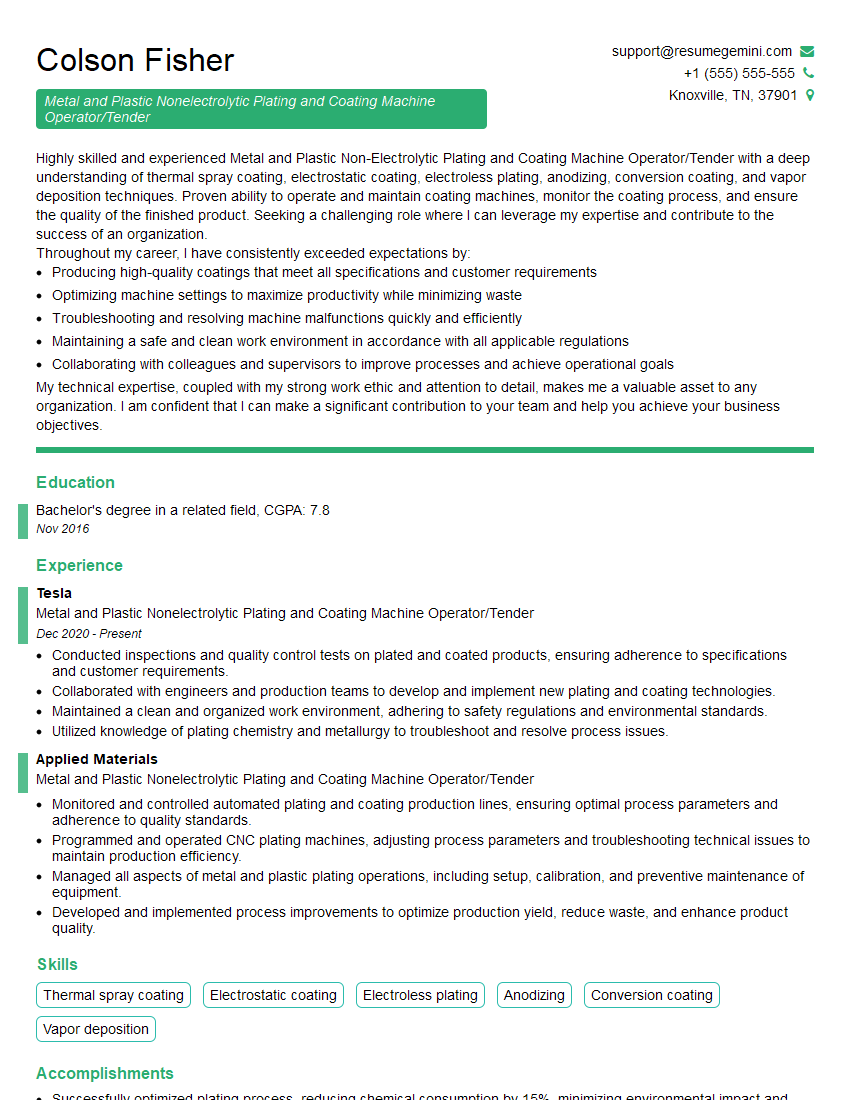

Colson Fisher

Metal and Plastic Nonelectrolytic Plating and Coating Machine Operator/Tender

Summary

Highly skilled and experienced Metal and Plastic Non-Electrolytic Plating and Coating Machine Operator/Tender with a deep understanding of thermal spray coating, electrostatic coating, electroless plating, anodizing, conversion coating, and vapor deposition techniques. Proven ability to operate and maintain coating machines, monitor the coating process, and ensure the quality of the finished product. Seeking a challenging role where I can leverage my expertise and contribute to the success of an organization.

Throughout my career, I have consistently exceeded expectations by:

- Producing high-quality coatings that meet all specifications and customer requirements

- Optimizing machine settings to maximize productivity while minimizing waste

- Troubleshooting and resolving machine malfunctions quickly and efficiently

- Maintaining a safe and clean work environment in accordance with all applicable regulations

- Collaborating with colleagues and supervisors to improve processes and achieve operational goals

My technical expertise, coupled with my strong work ethic and attention to detail, makes me a valuable asset to any organization. I am confident that I can make a significant contribution to your team and help you achieve your business objectives.

Education

Bachelor’s degree in a related field

November 2016

Skills

- Thermal spray coating

- Electrostatic coating

- Electroless plating

- Anodizing

- Conversion coating

- Vapor deposition

Work Experience

Metal and Plastic Nonelectrolytic Plating and Coating Machine Operator/Tender

- Conducted inspections and quality control tests on plated and coated products, ensuring adherence to specifications and customer requirements.

- Collaborated with engineers and production teams to develop and implement new plating and coating technologies.

- Maintained a clean and organized work environment, adhering to safety regulations and environmental standards.

- Utilized knowledge of plating chemistry and metallurgy to troubleshoot and resolve process issues.

Metal and Plastic Nonelectrolytic Plating and Coating Machine Operator/Tender

- Monitored and controlled automated plating and coating production lines, ensuring optimal process parameters and adherence to quality standards.

- Programmed and operated CNC plating machines, adjusting process parameters and troubleshooting technical issues to maintain production efficiency.

- Managed all aspects of metal and plastic plating operations, including setup, calibration, and preventive maintenance of equipment.

- Developed and implemented process improvements to optimize production yield, reduce waste, and enhance product quality.

Accomplishments

- Successfully optimized plating process, reducing chemical consumption by 15%, minimizing environmental impact and cost.

- Developed new coating technique, enhancing product durability and extending product life by 20%.

- Implemented automated control system, improving process accuracy and reducing downtime by 12%.

- Reduced scrap rate by 10% through meticulous monitoring, preventative maintenance, and prompt troubleshooting.

- Trained and mentored junior operators, fostering a productive and skilled work environment.

Awards

- Received Operator of the Year award for exceptional contributions to production efficiency and quality.

- Recognized for outstanding achievement in developing an innovative plating technique that enhanced product durability.

- Awarded for implementing a comprehensive safety program that significantly reduced workplace accidents.

- Received Excellence in Training award for mentoring and developing junior operators.

Certificates

- Certified Plating and Coating Technician (CPCT)

- Certified Coating Inspector (CCI)

- Certified Corrosion Specialist (CCS)

- Certified Manufacturing Technologist (CMfgT)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Metal and Plastic Nonelectrolytic Plating and Coating Machine Operator/Tender

- Emphasize your experience in the operation and maintenance of metal and plastic plating and coating machines.

- Highlight your knowledge of coating processes and your ability to ensure the quality of the finished product.

- Demonstrate your ability to troubleshoot and resolve machine malfunctions.

- Quantify your accomplishments and provide specific examples of how you have contributed to the success of your organization.

- Proofread your resume carefully for any errors in grammar or spelling.

Essential Experience Highlights for a Strong Metal and Plastic Nonelectrolytic Plating and Coating Machine Operator/Tender Resume

- Operate and maintain metal and plastic non-electrolytic plating and coating machines

- Monitor the coating process and make adjustments as needed

- Ensure the quality of the finished product meets customer specifications

- Troubleshoot and resolve machine malfunctions

- Maintain a safe and clean work environment

- Follow all applicable safety regulations

- May perform other duties as assigned

Frequently Asked Questions (FAQ’s) For Metal and Plastic Nonelectrolytic Plating and Coating Machine Operator/Tender

What is the job outlook for metal and plastic non-electrolytic plating and coating machine operators and tenders?

The job outlook for metal and plastic non-electrolytic plating and coating machine operators and tenders is expected to grow 4% from 2022 to 2032, faster than the average for all occupations. This growth is expected to be driven by the increasing demand for coated products in a variety of industries, including automotive, electronics, and construction.

What are the educational requirements for becoming a metal and plastic non-electrolytic plating and coating machine operator or tender?

Most employers require at least a high school diploma or equivalent. Some employers may prefer candidates with a postsecondary degree in a related field, such as chemistry or engineering.

What are the skills and experience required for becoming a metal and plastic non-electrolytic plating and coating machine operator or tender?

Metal and plastic non-electrolytic plating and coating machine operators and tenders need to have a good understanding of the coating process and the different types of coatings that can be applied to metal and plastic. They also need to be able to operate and maintain coating machines and troubleshoot any problems that may occur. In addition, metal and plastic non-electrolytic plating and coating machine operators and tenders need to be able to work independently and follow instructions carefully.

What is the average salary for a metal and plastic non-electrolytic plating and coating machine operator or tender?

The average salary for a metal and plastic non-electrolytic plating and coating machine operator or tender was $49,260 in May 2022. However, salaries can vary depending on the level of experience, the size of the company, and the location of the job.

What are the job duties of a metal and plastic non-electrolytic plating and coating machine operator or tender?

Metal and plastic non-electrolytic plating and coating machine operators and tenders perform a variety of duties, including operating and maintaining coating machines, monitoring the coating process, and ensuring the quality of the finished product. They also troubleshoot and resolve machine malfunctions, maintain a safe and clean work environment, and follow all applicable safety regulations.

What are the working conditions for a metal and plastic non-electrolytic plating and coating machine operator or tender?

Metal and plastic non-electrolytic plating and coating machine operators and tenders typically work in a manufacturing environment. They may be exposed to loud noises, fumes, and chemicals. They may also need to wear protective clothing and equipment, such as gloves, goggles, and masks.

What are the career prospects for a metal and plastic non-electrolytic plating and coating machine operator or tender?

Metal and plastic non-electrolytic plating and coating machine operators and tenders can advance to supervisory or management positions with experience and additional training. They may also be able to start their own businesses.