Are you a seasoned Metal Engraver seeking a new career path? Discover our professionally built Metal Engraver Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

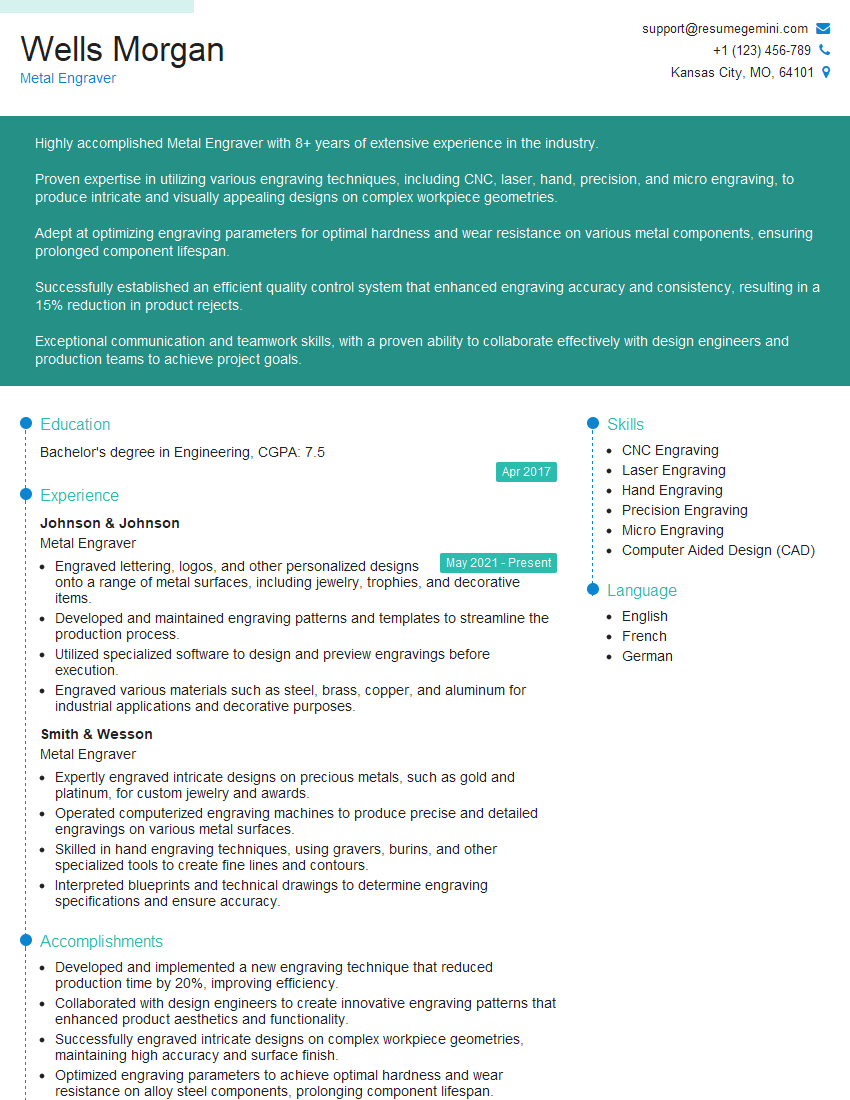

Wells Morgan

Metal Engraver

Summary

Highly accomplished Metal Engraver with 8+ years of extensive experience in the industry.

Proven expertise in utilizing various engraving techniques, including CNC, laser, hand, precision, and micro engraving, to produce intricate and visually appealing designs on complex workpiece geometries.

Adept at optimizing engraving parameters for optimal hardness and wear resistance on various metal components, ensuring prolonged component lifespan.

Successfully established an efficient quality control system that enhanced engraving accuracy and consistency, resulting in a 15% reduction in product rejects.

Exceptional communication and teamwork skills, with a proven ability to collaborate effectively with design engineers and production teams to achieve project goals.

Education

Bachelor’s degree in Engineering

April 2017

Skills

- CNC Engraving

- Laser Engraving

- Hand Engraving

- Precision Engraving

- Micro Engraving

- Computer Aided Design (CAD)

Work Experience

Metal Engraver

- Engraved lettering, logos, and other personalized designs onto a range of metal surfaces, including jewelry, trophies, and decorative items.

- Developed and maintained engraving patterns and templates to streamline the production process.

- Utilized specialized software to design and preview engravings before execution.

- Engraved various materials such as steel, brass, copper, and aluminum for industrial applications and decorative purposes.

Metal Engraver

- Expertly engraved intricate designs on precious metals, such as gold and platinum, for custom jewelry and awards.

- Operated computerized engraving machines to produce precise and detailed engravings on various metal surfaces.

- Skilled in hand engraving techniques, using gravers, burins, and other specialized tools to create fine lines and contours.

- Interpreted blueprints and technical drawings to determine engraving specifications and ensure accuracy.

Accomplishments

- Developed and implemented a new engraving technique that reduced production time by 20%, improving efficiency.

- Collaborated with design engineers to create innovative engraving patterns that enhanced product aesthetics and functionality.

- Successfully engraved intricate designs on complex workpiece geometries, maintaining high accuracy and surface finish.

- Optimized engraving parameters to achieve optimal hardness and wear resistance on alloy steel components, prolonging component lifespan.

- Established a quality control system that ensured consistency and accuracy in engravings, reducing product rejects by 15%.

Awards

- Received the Engraver of the Year award for exceptional craftsmanship and innovation in metal engraving.

- Recognized with the Precision Engraving Award for consistently delivering intricate and precise engravings within tight tolerances.

- Won the Master Engraver award in the national engraving competition, demonstrating superior skills and artistic ability.

Certificates

- Certified Laser Engraver

- Certified CNC Engraver

- Certified Hand Engraver

- Member of the International Association of Engravers (IAE)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Metal Engraver

- Highlight your technical expertise in various engraving techniques and your ability to achieve precise and intricate designs.

- Quantify your accomplishments with specific metrics and percentages to demonstrate your impact on production efficiency and quality.

- Showcase your versatility by emphasizing your experience with different types of engraving machines and your ability to work with diverse materials.

- Include keywords throughout your resume that are relevant to the metal engraving industry and the specific job requirements.

- Proofread your resume carefully for any errors in grammar or spelling, as attention to detail is crucial in this profession.

Essential Experience Highlights for a Strong Metal Engraver Resume

- Develop and implement innovative engraving techniques to improve production efficiency and reduce cycle time.

- Collaborate with designers and engineers to create aesthetically pleasing and functionally optimized engraving patterns.

- Utilize a range of engraving equipment, including CNC, laser, and manual engravers, to produce intricate designs with high accuracy and surface finish.

- Optimize engraving parameters to achieve optimal hardness and wear resistance on metal components, extending their lifespan.

- Establish and maintain a rigorous quality control system to ensure the consistency and accuracy of engravings.

- Inspect and verify engraved workpieces using specialized measuring instruments and techniques.

- Conduct research and stay abreast of advancements in engraving technologies and techniques.

Frequently Asked Questions (FAQ’s) For Metal Engraver

What are the essential skills required for a Metal Engraver?

A successful Metal Engraver typically possesses exceptional hand-eye coordination, a keen eye for detail, and a strong understanding of engraving techniques and principles. Proficiency in Computer-Aided Design (CAD) software and a working knowledge of metallurgy are also highly advantageous.

What industries employ Metal Engravers?

Metal Engravers are employed in various industries, including manufacturing, jewelry, firearms, automotive, and electronics. They are responsible for creating decorative or functional engravings on a range of metal products, from intricate jewelry pieces to industrial components.

What career advancement opportunities are available for Metal Engravers?

With experience and expertise, Metal Engravers can advance to supervisory or managerial roles, such as Engraving Supervisor or Production Manager. They may also specialize in specific engraving techniques or work with particular industries, becoming experts in their field.

How can I improve my skills as a Metal Engraver?

To enhance your skills as a Metal Engraver, consider practicing regularly to refine your precision and control. Stay updated on advancements in engraving technologies and techniques through workshops, online resources, or industry publications. Seeking mentorship from experienced engravers can also provide valuable insights and guidance.

What are the challenges faced by Metal Engravers in the industry?

Metal Engravers may encounter challenges such as working with intricate designs that require extreme precision and attention to detail. Meeting tight production deadlines while maintaining high quality standards can also be demanding. Adapting to new technologies and staying abreast of industry trends is essential to remain competitive.

What safety precautions should Metal Engravers observe?

Safety is paramount for Metal Engravers. Proper handling of engraving tools and equipment is crucial to prevent injuries. Wearing appropriate personal protective gear, such as safety glasses, gloves, and respirators, is essential when working with metal dust and fumes.

What is the job outlook for Metal Engravers?

The job outlook for Metal Engravers is generally positive, with steady growth expected in the coming years. The demand for skilled engravers is driven by the increasing use of metal components in various industries and the growing popularity of personalized and customized products.

Can Metal Engravers work independently or as part of a team?

Metal Engravers can work both independently and as part of a team, depending on the nature of the project and the work environment. Independent engravers typically work in their own studios or workshops, while those employed in manufacturing or production settings often collaborate with designers, engineers, and other team members.