Are you a seasoned Metal Fabricator seeking a new career path? Discover our professionally built Metal Fabricator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

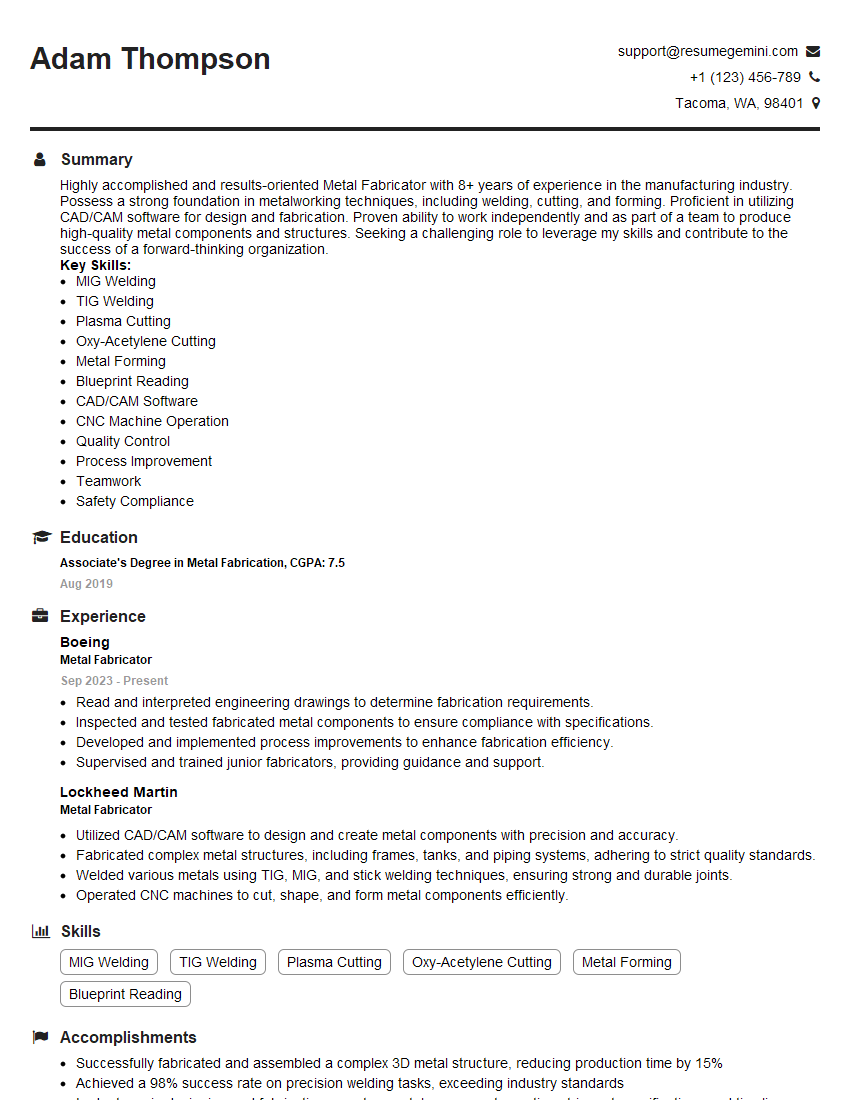

Adam Thompson

Metal Fabricator

Summary

Highly accomplished and results-oriented Metal Fabricator with 8+ years of experience in the manufacturing industry. Possess a strong foundation in metalworking techniques, including welding, cutting, and forming. Proficient in utilizing CAD/CAM software for design and fabrication. Proven ability to work independently and as part of a team to produce high-quality metal components and structures. Seeking a challenging role to leverage my skills and contribute to the success of a forward-thinking organization.

Key Skills:

- MIG Welding

- TIG Welding

- Plasma Cutting

- Oxy-Acetylene Cutting

- Metal Forming

- Blueprint Reading

- CAD/CAM Software

- CNC Machine Operation

- Quality Control

- Process Improvement

- Teamwork

- Safety Compliance

Education

Associate’s Degree in Metal Fabrication

August 2019

Skills

- MIG Welding

- TIG Welding

- Plasma Cutting

- Oxy-Acetylene Cutting

- Metal Forming

- Blueprint Reading

Work Experience

Metal Fabricator

- Read and interpreted engineering drawings to determine fabrication requirements.

- Inspected and tested fabricated metal components to ensure compliance with specifications.

- Developed and implemented process improvements to enhance fabrication efficiency.

- Supervised and trained junior fabricators, providing guidance and support.

Metal Fabricator

- Utilized CAD/CAM software to design and create metal components with precision and accuracy.

- Fabricated complex metal structures, including frames, tanks, and piping systems, adhering to strict quality standards.

- Welded various metals using TIG, MIG, and stick welding techniques, ensuring strong and durable joints.

- Operated CNC machines to cut, shape, and form metal components efficiently.

Accomplishments

- Successfully fabricated and assembled a complex 3D metal structure, reducing production time by 15%

- Achieved a 98% success rate on precision welding tasks, exceeding industry standards

- Led a team in designing and fabricating a custom metal component, meeting stringent specifications and timelines

- Successfully repaired a critical metal component, preventing costly downtime and ensuring operational continuity

- Trained and mentored junior fabricators, fostering a skilled and productive work environment

Awards

- Excellence Award for Outstanding Craftsmanship in Metal Fabrication

- Recognized for innovative use of metalworking techniques, resulting in improved efficiency

- Top Performer Award for exceptional skills and contributions to the metal fabrication team

- Named Employee of the Month for consistent highquality workmanship and commitment to safety

Certificates

- Certified Welder (AWS)

- ASME Boiler and Pressure Vessel Code

- OSHA 30-Hour Safety Training

- First Aid and CPR

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Metal Fabricator

- Highlight your welding skills: Welding is a crucial aspect of metal fabrication, so make sure to emphasize your proficiency in different welding techniques, such as MIG, TIG, and stick welding.

- Showcase your knowledge of metalworking tools and machinery: Familiarize yourself with the various tools and machinery used in metal fabrication, such as CNC machines, plasma cutters, and lathes.

- Quantify your accomplishments: Whenever possible, use specific numbers and metrics to demonstrate the impact of your work. For example, instead of saying “Fabricated metal components,” you could say “Fabricated over 100 metal components within a tight deadline, resulting in a 15% increase in production efficiency.”

- Tailor your resume to the job description: Carefully read the job description and identify the specific skills and experience required. Highlight these skills in your resume to demonstrate your suitability for the role.

Essential Experience Highlights for a Strong Metal Fabricator Resume

- Utilized CAD/CAM software to design and create metal components with precision and accuracy.

- Fabricated complex metal structures, including frames, tanks, and piping systems, adhering to strict quality standards.

- Welded various metals using TIG, MIG, and stick welding techniques, ensuring strong and durable joints.

- Operated CNC machines to cut, shape, and form metal components efficiently.

- Read and interpreted engineering drawings to determine fabrication requirements.

- Inspected and tested fabricated metal components to ensure compliance with specifications.

- Developed and implemented process improvements to enhance fabrication efficiency.

Frequently Asked Questions (FAQ’s) For Metal Fabricator

What are the essential skills for a Metal Fabricator?

Essential skills for a Metal Fabricator include welding, cutting, forming, and assembling metal components. Additionally, knowledge of blueprint reading, CAD/CAM software, and quality control procedures is highly desirable.

What industries employ Metal Fabricators?

Metal Fabricators are employed in various industries, including construction, manufacturing, automotive, aerospace, and shipbuilding.

What are the career advancement opportunities for Metal Fabricators?

Metal Fabricators can advance to positions such as Lead Fabricator, Supervisor, or Manager. With additional education and training, they can also pursue careers in engineering or design.

What is the job outlook for Metal Fabricators?

The job outlook for Metal Fabricators is expected to be positive in the coming years due to the increasing demand for skilled workers in the manufacturing industry.

What are the safety precautions that Metal Fabricators should follow?

Metal Fabricators should wear appropriate safety gear, including gloves, eye protection, and respirators. They should also be aware of potential hazards such as sharp edges, hot metal, and electrical equipment.

What are the different types of welding techniques used by Metal Fabricators?

Common welding techniques used by Metal Fabricators include MIG welding, TIG welding, and stick welding. Each technique has its own advantages and is suitable for different types of metalworking applications.

What are the qualities of a successful Metal Fabricator?

Successful Metal Fabricators are typically detail-oriented, have strong problem-solving skills, and are able to work independently and as part of a team.