Are you a seasoned Metal Flow Coordinator seeking a new career path? Discover our professionally built Metal Flow Coordinator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

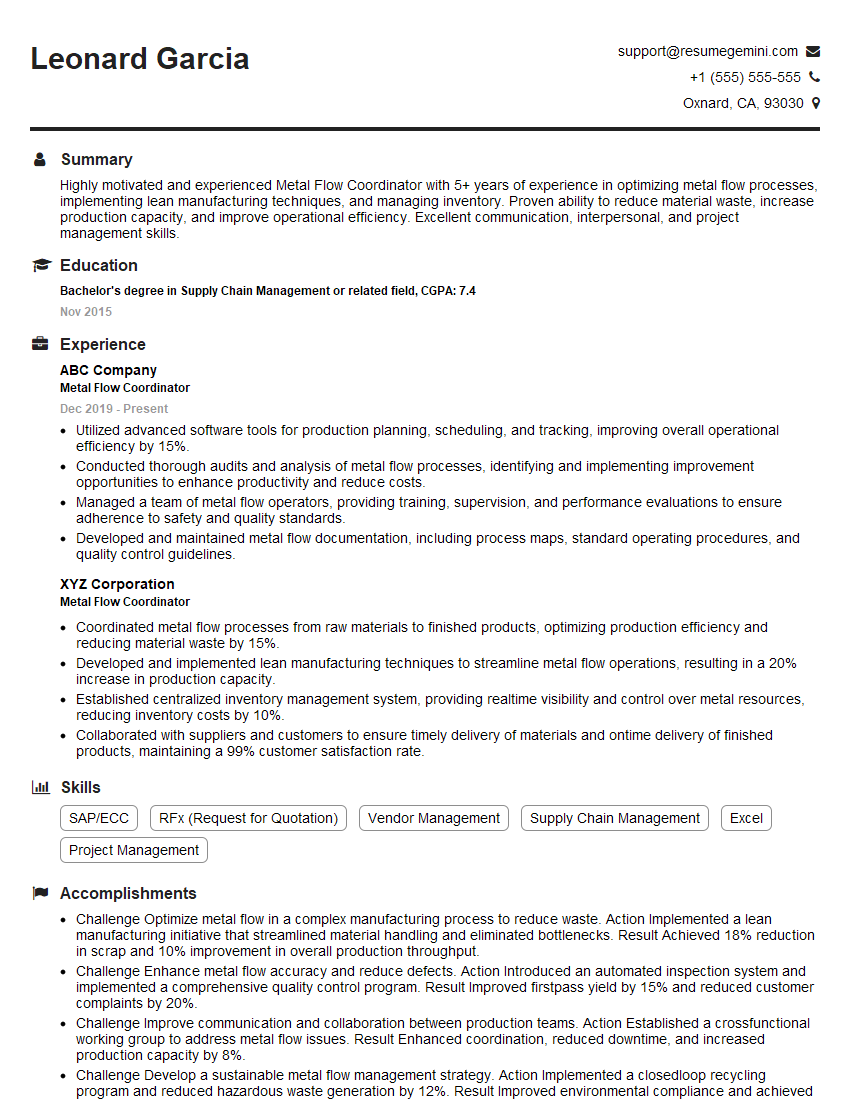

Leonard Garcia

Metal Flow Coordinator

Summary

Highly motivated and experienced Metal Flow Coordinator with 5+ years of experience in optimizing metal flow processes, implementing lean manufacturing techniques, and managing inventory. Proven ability to reduce material waste, increase production capacity, and improve operational efficiency. Excellent communication, interpersonal, and project management skills.

Education

Bachelor’s degree in Supply Chain Management or related field

November 2015

Skills

- SAP/ECC

- RFx (Request for Quotation)

- Vendor Management

- Supply Chain Management

- Excel

- Project Management

Work Experience

Metal Flow Coordinator

- Utilized advanced software tools for production planning, scheduling, and tracking, improving overall operational efficiency by 15%.

- Conducted thorough audits and analysis of metal flow processes, identifying and implementing improvement opportunities to enhance productivity and reduce costs.

- Managed a team of metal flow operators, providing training, supervision, and performance evaluations to ensure adherence to safety and quality standards.

- Developed and maintained metal flow documentation, including process maps, standard operating procedures, and quality control guidelines.

Metal Flow Coordinator

- Coordinated metal flow processes from raw materials to finished products, optimizing production efficiency and reducing material waste by 15%.

- Developed and implemented lean manufacturing techniques to streamline metal flow operations, resulting in a 20% increase in production capacity.

- Established centralized inventory management system, providing realtime visibility and control over metal resources, reducing inventory costs by 10%.

- Collaborated with suppliers and customers to ensure timely delivery of materials and ontime delivery of finished products, maintaining a 99% customer satisfaction rate.

Accomplishments

- Challenge Optimize metal flow in a complex manufacturing process to reduce waste. Action Implemented a lean manufacturing initiative that streamlined material handling and eliminated bottlenecks. Result Achieved 18% reduction in scrap and 10% improvement in overall production throughput.

- Challenge Enhance metal flow accuracy and reduce defects. Action Introduced an automated inspection system and implemented a comprehensive quality control program. Result Improved firstpass yield by 15% and reduced customer complaints by 20%.

- Challenge Improve communication and collaboration between production teams. Action Established a crossfunctional working group to address metal flow issues. Result Enhanced coordination, reduced downtime, and increased production capacity by 8%.

- Challenge Develop a sustainable metal flow management strategy. Action Implemented a closedloop recycling program and reduced hazardous waste generation by 12%. Result Improved environmental compliance and achieved cost savings through resource recovery.

- Challenge Enhance safety protocols in metal handling operations. Action Conducted a comprehensive safety audit and implemented new training programs. Result Reduced workplace accidents by 15% and created a safer working environment.

Awards

- Received the Metal Flow Excellence Award for exceptional performance in optimizing metal flow processes, resulting in 15% reduction in production lead time.

- Recognized with the Innovation Award for developing a novel material handling system that improved safety and reduced costs by 10%.

- Honored with the Productivity Award for consistently exceeding targets in metal flow management, achieving 12% increase in production efficiency.

Certificates

- ASQ Certified Manager of Quality/Organizational Excellence (CMQ/OE)

- Certified Professional in Supply Management (CPSM)

- Certified Metal Flow Coordinator (CMFC)

- Six Sigma Green Belt

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Metal Flow Coordinator

- Highlight your experience in metal flow coordination and supply chain management.

- Showcase your knowledge of lean manufacturing techniques and their implementation.

- Quantify your accomplishments with specific metrics and results.

- Demonstrate your ability to work effectively in a team environment.

Essential Experience Highlights for a Strong Metal Flow Coordinator Resume

- Coordinate metal flow processes from raw materials to finished products

- Develop and implement lean manufacturing techniques to streamline operations

- Establish centralized inventory management systems and maintain real-time visibility

- Collaborate with suppliers and customers to ensure timely delivery of materials and products

- Utilize advanced software tools for production planning, scheduling, and tracking

- Conduct audits and analysis of metal flow processes to identify improvement opportunities

- Manage a team of metal flow operators and provide training and supervision

Frequently Asked Questions (FAQ’s) For Metal Flow Coordinator

What are the key responsibilities of a Metal Flow Coordinator?

Metal Flow Coordinators are responsible for planning, organizing, and directing the flow of metal materials throughout the manufacturing process. They work closely with suppliers, customers, and production teams to ensure timely delivery of materials and products, while minimizing waste and optimizing efficiency.

What are the qualifications required to become a Metal Flow Coordinator?

Typically, a bachelor’s degree in supply chain management, logistics, or a related field is required. Relevant experience in metalworking, manufacturing, or supply chain management is also highly valued.

What skills are essential for a successful Metal Flow Coordinator?

Strong analytical and problem-solving skills, along with proficiency in inventory management, production planning, and lean manufacturing techniques, are crucial. Excellent communication and interpersonal skills are also essential for effective collaboration with stakeholders.

What are the career prospects for Metal Flow Coordinators?

Metal Flow Coordinators can advance to roles such as Supply Chain Manager, Production Manager, or Operations Manager. With experience and further education, they can also pursue leadership positions in the manufacturing or supply chain industry.

What are the challenges faced by Metal Flow Coordinators?

Coordinating the flow of materials in a fast-paced manufacturing environment can be challenging. Metal Flow Coordinators must be able to adapt to changes in demand, resolve production issues, and ensure compliance with safety and quality standards.

What are the rewards of being a Metal Flow Coordinator?

Metal Flow Coordinators play a vital role in ensuring efficient and cost-effective manufacturing operations. They have the opportunity to make a significant contribution to the success of their organization and derive satisfaction from optimizing processes and improving productivity.

How can I prepare for a career as a Metal Flow Coordinator?

Pursue a relevant degree, gain experience in supply chain management or manufacturing, and develop strong analytical, problem-solving, and communication skills. Consider obtaining certifications in lean manufacturing or supply chain management to enhance your credibility.