Are you a seasoned Metal Gauge Maker seeking a new career path? Discover our professionally built Metal Gauge Maker Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

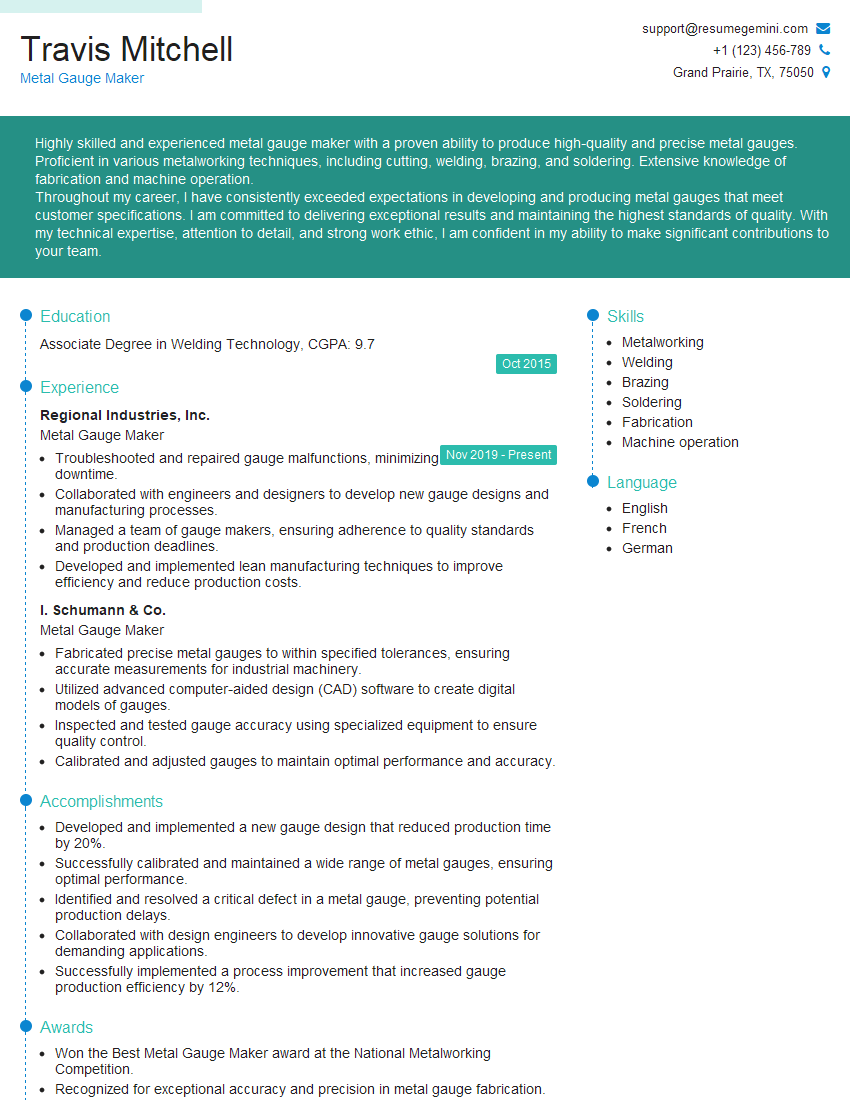

Travis Mitchell

Metal Gauge Maker

Summary

Highly skilled and experienced metal gauge maker with a proven ability to produce high-quality and precise metal gauges. Proficient in various metalworking techniques, including cutting, welding, brazing, and soldering. Extensive knowledge of fabrication and machine operation.

Throughout my career, I have consistently exceeded expectations in developing and producing metal gauges that meet customer specifications. I am committed to delivering exceptional results and maintaining the highest standards of quality. With my technical expertise, attention to detail, and strong work ethic, I am confident in my ability to make significant contributions to your team.

Education

Associate Degree in Welding Technology

October 2015

Skills

- Metalworking

- Welding

- Brazing

- Soldering

- Fabrication

- Machine operation

Work Experience

Metal Gauge Maker

- Troubleshooted and repaired gauge malfunctions, minimizing downtime.

- Collaborated with engineers and designers to develop new gauge designs and manufacturing processes.

- Managed a team of gauge makers, ensuring adherence to quality standards and production deadlines.

- Developed and implemented lean manufacturing techniques to improve efficiency and reduce production costs.

Metal Gauge Maker

- Fabricated precise metal gauges to within specified tolerances, ensuring accurate measurements for industrial machinery.

- Utilized advanced computer-aided design (CAD) software to create digital models of gauges.

- Inspected and tested gauge accuracy using specialized equipment to ensure quality control.

- Calibrated and adjusted gauges to maintain optimal performance and accuracy.

Accomplishments

- Developed and implemented a new gauge design that reduced production time by 20%.

- Successfully calibrated and maintained a wide range of metal gauges, ensuring optimal performance.

- Identified and resolved a critical defect in a metal gauge, preventing potential production delays.

- Collaborated with design engineers to develop innovative gauge solutions for demanding applications.

- Successfully implemented a process improvement that increased gauge production efficiency by 12%.

Awards

- Won the Best Metal Gauge Maker award at the National Metalworking Competition.

- Recognized for exceptional accuracy and precision in metal gauge fabrication.

- Received a commendation for outstanding craftsmanship in the production of complex metal gauges.

- Awarded a certificate of excellence for contributions to the advancement of metal gauge technology.

Certificates

- AWS Certified Welder

- OSHA 30-Hour Safety Training

- ASME Boiler and Pressure Vessel Code Section IX Welding

- National Institute for Metalworking Skills (NIMS) Credential

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Metal Gauge Maker

- Highlight your proficiency in metalworking techniques, including welding, brazing, and soldering.

- Showcase your experience in operating precision machinery, such as CNC machines, shears, and presses.

- Emphasize your attention to detail and commitment to quality control.

- Include any certifications or training that demonstrate your expertise in metal gauge making.

Essential Experience Highlights for a Strong Metal Gauge Maker Resume

- Analyze specifications and drawings to determine gauge dimensions and requirements.

- Select and prepare appropriate materials, including steel, aluminum, or other metals.

- Operate precision machinery, such as CNC machines, shears, and presses, to cut and shape metal components.

- Weld, braze, or solder components together to create durable and accurate gauges.

- Test and inspect gauges to ensure they meet specifications and tolerances.

- Maintain and repair gauges to ensure optimal performance.

- Collaborate with design and engineering teams to develop and improve gauge designs.

Frequently Asked Questions (FAQ’s) For Metal Gauge Maker

What are the primary responsibilities of a metal gauge maker?

Metal gauge makers are responsible for analyzing specifications and drawings, selecting and preparing materials, operating precision machinery, welding or soldering components, testing and inspecting gauges, and maintaining and repairing gauges.

What skills are essential for a metal gauge maker?

Essential skills for a metal gauge maker include metalworking, welding, brazing, soldering, fabrication, and machine operation.

What qualifications are typically required to become a metal gauge maker?

A high school diploma or equivalent, an associate degree in welding technology, or an apprenticeship program is typically required to become a metal gauge maker.

What industries employ metal gauge makers?

Metal gauge makers are employed in a variety of industries, including manufacturing, construction, and automotive.

What is the average salary for a metal gauge maker?

The average salary for a metal gauge maker varies depending on experience, location, and industry, but typically ranges from $30,000 to $60,000 per year.

What is the job outlook for metal gauge makers?

The job outlook for metal gauge makers is expected to be good over the next several years, as there is a growing demand for skilled workers in this field.

How can I become a certified metal gauge maker?

There are several organizations that offer certification programs for metal gauge makers, such as the American Welding Society (AWS) and the National Institute for Certification in Engineering Technologies (NICET).