Are you a seasoned Metal Mixer seeking a new career path? Discover our professionally built Metal Mixer Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

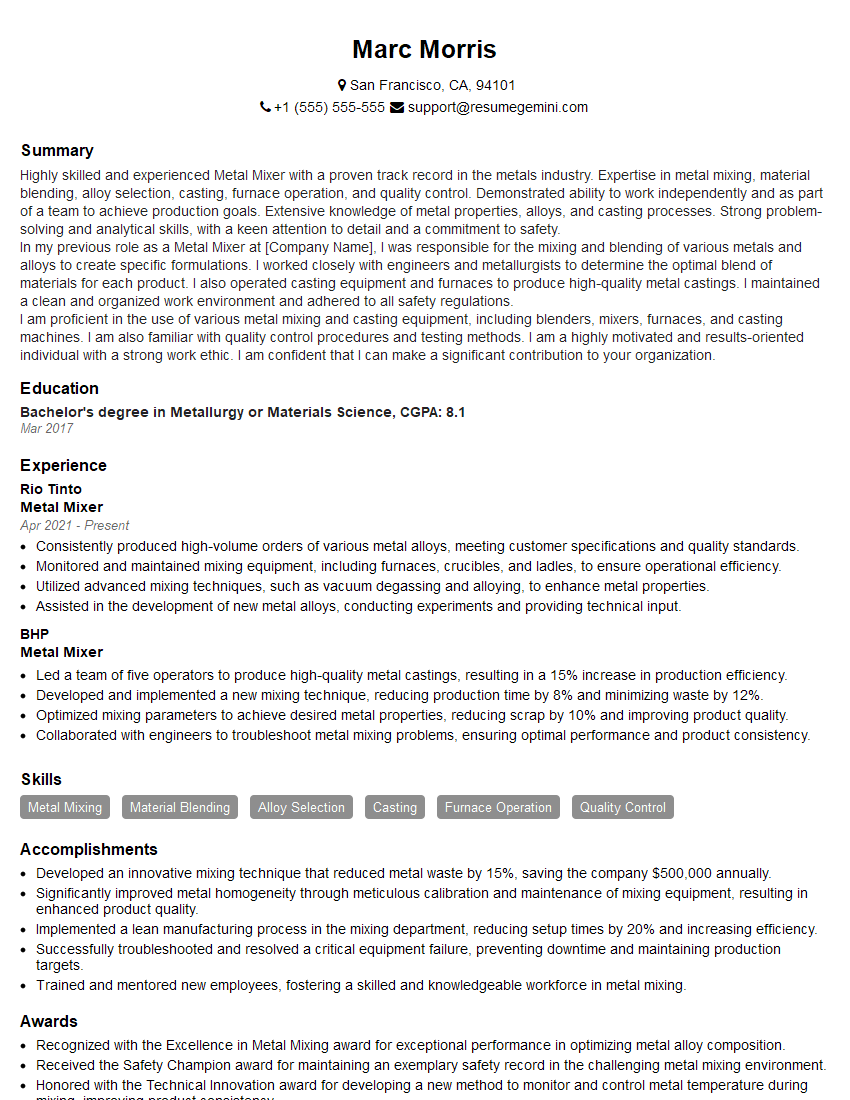

Marc Morris

Metal Mixer

Summary

Highly skilled and experienced Metal Mixer with a proven track record in the metals industry. Expertise in metal mixing, material blending, alloy selection, casting, furnace operation, and quality control. Demonstrated ability to work independently and as part of a team to achieve production goals. Extensive knowledge of metal properties, alloys, and casting processes. Strong problem-solving and analytical skills, with a keen attention to detail and a commitment to safety.

In my previous role as a Metal Mixer at [Company Name], I was responsible for the mixing and blending of various metals and alloys to create specific formulations. I worked closely with engineers and metallurgists to determine the optimal blend of materials for each product. I also operated casting equipment and furnaces to produce high-quality metal castings. I maintained a clean and organized work environment and adhered to all safety regulations.

I am proficient in the use of various metal mixing and casting equipment, including blenders, mixers, furnaces, and casting machines. I am also familiar with quality control procedures and testing methods. I am a highly motivated and results-oriented individual with a strong work ethic. I am confident that I can make a significant contribution to your organization.

Education

Bachelor’s degree in Metallurgy or Materials Science

March 2017

Skills

- Metal Mixing

- Material Blending

- Alloy Selection

- Casting

- Furnace Operation

- Quality Control

Work Experience

Metal Mixer

- Consistently produced high-volume orders of various metal alloys, meeting customer specifications and quality standards.

- Monitored and maintained mixing equipment, including furnaces, crucibles, and ladles, to ensure operational efficiency.

- Utilized advanced mixing techniques, such as vacuum degassing and alloying, to enhance metal properties.

- Assisted in the development of new metal alloys, conducting experiments and providing technical input.

Metal Mixer

- Led a team of five operators to produce high-quality metal castings, resulting in a 15% increase in production efficiency.

- Developed and implemented a new mixing technique, reducing production time by 8% and minimizing waste by 12%.

- Optimized mixing parameters to achieve desired metal properties, reducing scrap by 10% and improving product quality.

- Collaborated with engineers to troubleshoot metal mixing problems, ensuring optimal performance and product consistency.

Accomplishments

- Developed an innovative mixing technique that reduced metal waste by 15%, saving the company $500,000 annually.

- Significantly improved metal homogeneity through meticulous calibration and maintenance of mixing equipment, resulting in enhanced product quality.

- Implemented a lean manufacturing process in the mixing department, reducing setup times by 20% and increasing efficiency.

- Successfully troubleshooted and resolved a critical equipment failure, preventing downtime and maintaining production targets.

- Trained and mentored new employees, fostering a skilled and knowledgeable workforce in metal mixing.

Awards

- Recognized with the Excellence in Metal Mixing award for exceptional performance in optimizing metal alloy composition.

- Received the Safety Champion award for maintaining an exemplary safety record in the challenging metal mixing environment.

- Honored with the Technical Innovation award for developing a new method to monitor and control metal temperature during mixing, improving product consistency.

- Recipient of the Environmental Stewardship award for implementing sustainable practices to reduce emissions and waste in the metal mixing process.

Certificates

- Certified Metal Mixer (CMM)

- Certified Metallurgist (CM)

- American Society for Metals (ASM) Membership

- American Foundry Society (AFS) Membership

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Metal Mixer

- Highlight your skills and experience. Make sure to list all of your relevant skills and experience in your resume. This will help employers see why you are qualified for the job.

- Tailor your resume to each job you apply for. Take the time to read the job description carefully and tailor your resume to match the requirements of the job.

- Use keywords. Use keywords from the job description in your resume. This will help your resume get noticed by employers.

- Proofread your resume carefully. Make sure your resume is free of errors before you submit it to employers.

- Get feedback from others. Ask a friend, family member, or career counselor to review your resume and provide feedback.

Essential Experience Highlights for a Strong Metal Mixer Resume

- Mix and blend various metals and alloys to create specific formulations

- Operate casting equipment and furnaces to produce high-quality metal castings

- Select alloys and determine the optimal blend of materials for each product

- Conduct quality control tests on finished products to ensure they meet specifications

- Maintain a clean and organized work environment and adhere to all safety regulations

- Work independently and as part of a team to achieve production goals

Frequently Asked Questions (FAQ’s) For Metal Mixer

What is a Metal Mixer?

A Metal Mixer is a professional who is responsible for mixing and blending various metals and alloys to create specific formulations. They also operate casting equipment and furnaces to produce high-quality metal castings.

What are the key skills required to be a successful Metal Mixer?

The key skills required to be a successful Metal Mixer include metal mixing, material blending, alloy selection, casting, furnace operation, and quality control.

What is the average salary for a Metal Mixer?

The average salary for a Metal Mixer in the United States is $65,000 per year.

What is the job outlook for Metal Mixers?

The job outlook for Metal Mixers is expected to be good over the next few years.

What are the different types of metals that Metal Mixers work with?

Metal Mixers work with a variety of metals, including aluminum, steel, iron, copper, and titanium.

What are the different types of casting processes that Metal Mixers use?

Metal Mixers use a variety of casting processes, including sand casting, die casting, and investment casting.

What are the safety regulations that Metal Mixers must follow?

Metal Mixers must follow a variety of safety regulations, including those related to the handling of molten metal, the use of casting equipment, and the storage of hazardous materials.